Description

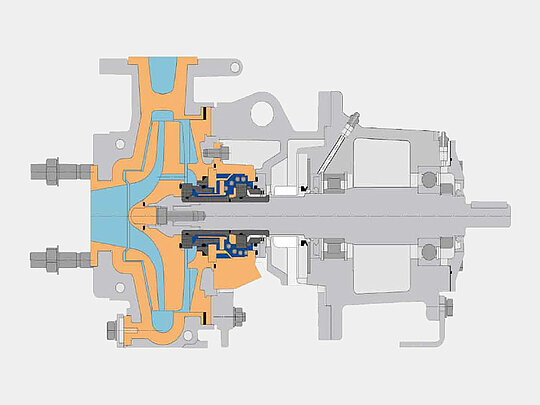

Standardized Chemical Pump CS/CS-B

Flexible all around talent

The CS Series chemical centrifugal pumps with shaft seal are the solution of choice for corrosive and abrasive service conditions and whenever it comes to pumping fluids posing a health and environmental hazard. This CS pump series has been specifically developed for applications in which the use of magnetically coupled pumps is not advisable or undesirable because of the tough service environment.

Casing dimensions, assembly dimensions and design according to SO2858 / ISO5199

Advantages

Good reasons for a Munsch CS or CS-B chemical pump

Resistant contact surface

All liquid-contacted pump components are fabricated from thick-walled PP and PVDF or universally chemical- resistant PFA plastics. The ceramic components of the mechanical seal combined with the secondary static seals manufactured from fluoroplastics make the pump quasi universally resistant.

Types of construction

The CS Series standardized pumps are designed with fitting dimensions to EN 22858, ISO 2858 and ISO 5199. For the CS-B Series close-coupled pumps, this applies only to the flange connections.

High-performance shaft seals

The CS/CS-B series can be supplied with either single- acting or double-acting metal-free mechanical seals. Ceramic components and a variety of flushing options make the pumps suitable for applications involving high solids loads.

Casing with high wear reserve

Volute casing with wall thicknesses of > 10 mm

Tolerant to solids

A solids deflector effectively keeps solids away from the shaft passage.

Options

Allowing flexibility to your application our CS pumps can be ordered with or without close-cloupling:

- Standardized CS pump

- Close-coupled CS-B pump

Further options:

- Continuous flushing

- Shutdown flushing

- Spring chamber flushing

- Volute casing drain

- Temperature sensor in volute casing

Technical Data

| Series | Pump capacity [Q] | Differential head [H] | Operating temperature [t] | Operating pressure [p] | Solids content | Particle size | Discharge nozzle | Motor rating |

|---|---|---|---|---|---|---|---|---|

| CS | up to 200 m³/h | up to 90 m | from -20°C to +180 °C | up to 16 bar | up to 5%-Vol. | up to 5 mm | DN 25 to DN 65 | up to 30kW |

| CS-B | up to 90 m³/h | up to 60 m | from -20°C to +180 °C | up to 16 bar | up to 5%-Vol. | up to 5 mm | DN 25 to DN 65 | up to 18,5kW |

Industries

Pumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsApplications

Amine treatment

At LEWA, you receive pumps and systems for amine treatment in power plants. Ask our experts for more information.

More DetailsPolymerization

LEWA manufactures metering pumps and metering systems for polymerization which optimally meet the necessary requirements. We are happy to help.

More DetailsProduction of biodiesel

LEWA provides metering systems for producing biodiesel and other biofuels. Consult us!

More DetailsDilution of surfactants

Dilution of surfactants such as sodium lauryl ether sulfate (SLES) with LEWA pumps during production of detergents.

More Details