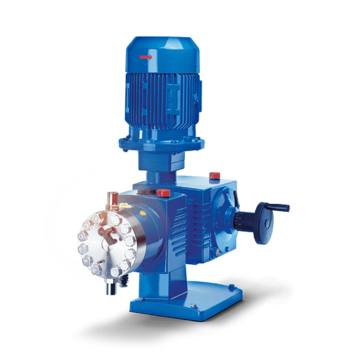

Metering pumps

Diaphragm and piston pumps

Our metering pumps (reciprocating positive displacement pumps) offer maximum metering accuracy and are the benchmark for safety, reliability and efficiency, especially when the conveyance of critical fluids is at stake. Within our selection, we offer both diaphragm and piston pumps.

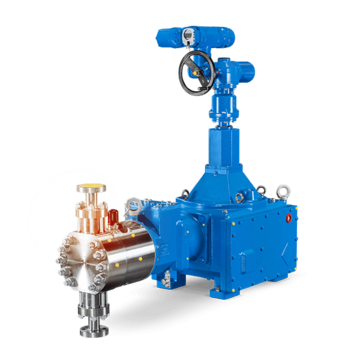

Process pumps

High performance, high pressure, high reliability

The LEWA triplex, LEWA ecoflow and LEWA plunger pumps are the industry benchmark for reliable, durable and energy-efficient pumps in high-pressure process technology. All components are designed and optimized for the appropriate application.

Rotary displacement pumps

Range of flow rates from a few l/h to several hundred m³/h

A relatively rigid compression curve makes these pumps ideal as feed pumps and metering pumps within their extensive range of flow rates. They are frequently a cost-effective alternative, especially in the food, pharmaceutical, and biotechnology industries, as well as for low pressure requirements.

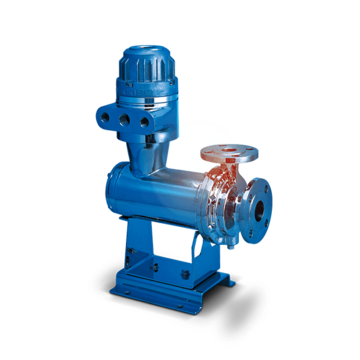

Centrifugal pumps

Are you looking for efficient, cost-effective transportation for large amounts of fluid?

If so, centrifugal pumps or rotary pumps could be the right choice for you. LEWA distributes centrifugal pumps from various manufacturers and for many different applications – the lowest temperatures (–162 °C), highest viscosities and abrasive fluids are routine for us.

What types of pumps are there?

On the basis of their functional principle, pumps can be divided into two main groups.

- Flow pumps or centrifugal pumps are characterized by fluid mechanical processes. In these industrial pumps, the medium flows through the machine without any flaps or valves. Non-return flaps, valves or slides prevent the conveyed medium from flowing back again when the machine is at a standstill. Flow pumps are usually not self-priming. Axial pumps, diagonal pumps and radial pumps are some classic examples of this type of pump.

- Positive displacement pumps are usually self-priming. The medium is conveyed through a self-contained vacuum. Valves and flaps or the force of gravity prevent a back flow at a standstill. Diaphragm pumps or piston pumps belong to this type of industrial pump.

Why should the right pump be selected for every system?

Pumps are used in different applications in various industries. In most cases, liquid should be conveyed or dosed. To ensure reliable and smooth operation at all times, the relevant pump technology must be adapted to the prevailing framework conditions.

These include:

- (not only extreme) temperatures

- pressure conditions

- Properties of the liquid to be pumped (aggressive, corrosive or solid matter)