Solutions for the mining industry and metal and mineral processing

Our specialized equipment for mining and metal and mineral processing meets all industry requirements. LEWA provides EPC companies, operators, and end-users with a comprehensive portfolio of advanced metering, process, and centrifugal pumps and pumping systems.

In developing our solutions, we consider industry standards alongside your specific needs and operational conditions. Our products feature a wide range of pressures and flows, hermetically sealed units, and high-efficiency designs to ensure utmost safety. LEWA pumps and systems, such as those equipped with sandwich PTFE diaphragms, offer enhanced pumping safety for handling hazardous materials like cyanides and sulfuric acids, ensuring maximum cost-efficiency.

With decades of experience, LEWA delivers international engineering and project expertise, supporting you through every phase of your project. Trust an experienced supplier—trust LEWA!

Background

Ores are typically extracted from formations such as orebodies, lodes, veins, seams, reefs, or placer deposits. The materials recovered through mining operations include a variety of resources such as metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clay.

LEWA pumps and pumping systems are expertly designed to handle any chemical fluid used in the extraction, processing, and finishing of valuable minerals or other geological materials from the earth.

For more detailed information on how our solutions can support your operations, please contact us!

Applications

| Process | Chemicals | Purpose |

|---|---|---|

| Size Reduction Processes | ||

| Spray drying | Mineral itself in suspension | Atomize, dry and homogenize the mineral into thin powder |

| Separation Processes | ||

| Leaching | Acid water | Lixiviant for copper, nickel and other metals |

| Activated Carbon | Gold extraction via adsorption of gold cyanide solution | |

| Anhydrous Ammonia | Lixiviant for nickel. Precipitant in uranium extraction | |

| Acqua Regia | Melting of palladium, gold and platinum | |

| Caustic Soda (Liquor & Pearl) | Elution stripping of gold adsorbed onto activated carbon | |

| Ferrous Sulphate | Cyanide detoxification in gold mining process | |

| Hydrochloric Acid | Pre‑elution treatment of activated carbon in gold mining | |

| Lead Nitrate | Accelerator in gold cyanidation | |

| Sodium Bisulphite (SBS) | Cyanide detoxification in gold mining | |

| Sodium Chlorate | Oxidant in uranium extraction | |

| Sodium Cyanide | Gold extraction using cyanidation heap leach, CIP or CIL processes | |

| Sodium Metabisulphite (SMBS) | Cyanide detoxification in gold mining | |

| Sulfuric Acid | Lixiviant in copper and nickel mining. Cyanide destruction in gold mining | |

| Flotation | Copper Sulphate Pentahydrate | Activator for sphalerite (ZnS), pyrite (FeS2) in base metal ores |

| Lead Nitrate | Activator for stibnite (Sb2S3) in antimony ores | |

| DSPcollectors | Range of specialty collectors | |

| Potassium Amyl Xanthate (PAX) | Strong, unselective collector | |

| Sodium Ethyl Xanthate (SEX) | Weak, highly selective collector | |

| Sodium Isobutyl Xanthate (SIBX) | Good general purpose collector | |

| Carboxymethyl Cellulose (CMC) | Selective collector with higher recovery than SEX | |

| Dextrin | Depressant for talc and gangue minerals in base metal ores | |

| Guar Gum | Organic Acid gangue depressant for orescontaining oxide minerals Depressant for carbon and galena (PbS) minerals in base metal ores Depressant for gangue minerals, particularly silicate in base metal ores | |

| Sodium Cyanide | Depressant for base metal ores | |

| Sodium Metabisulphite (SMBS) | Dispersant and pH control | |

| Sodium Sulphite | Range of specialty frothers | |

| Zinc Sulphate | Wide application general purpose frother | |

| Soda Ash | Sulfidising agent for oxide minerals | |

| DSF Frothers | Sulfidising agent and depressant for base metal ores | |

| Sodium Hydrosulphide | Gold precipitation | |

| Dewatering | Aluminium Sulphate | Inorganic flocculant for water treatment |

| Ferric Chloride | Inorganic flocculant for water treatment | |

| Ferric Sulphate | Inorganic flocculant for water treatment | |

| Polyacrylamide Flocculants | Range of nonionic, anionic and cationic polymers for thickening applications | |

| Refining Processes | ||

| Converting | Coal in suspension | Coal refinement through liquefaction |

| Solvents | Vehicle for suspension | |

| Oil | Vehicle for suspension | |

| Phenols | By-product of the conversion process | |

| Ammonia | By-product of the conversion process | |

| Hydrogen sulfide | By-product of the conversion process | |

| Hydrocyanic acid | By-product of the conversion process | |

| H2S scavenger | Agent to reduce the presence of sulfur(corrosive)in the process | |

| Paraffin | Final product | |

| Alcohols | Final product | |

More LEWA reference applications – In-depth information

Coal refinement with remote-head metering pumps in condensing systems

When coal is refined, it is ground as fine as dust and mixed into a suspension kept at a high temperature. LEWA metering pumps with a remote pump head are used for this.

More DetailsSulfuric acid injection in copper heap leaching

LEWA process pumps are used to reinject sulfuric acid at 98% into the main pipelines that go to the heap leach sprinklers.

More DetailsProducts

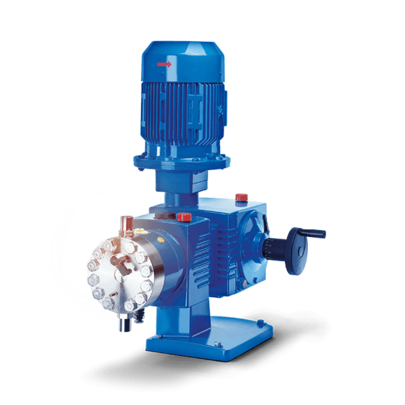

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

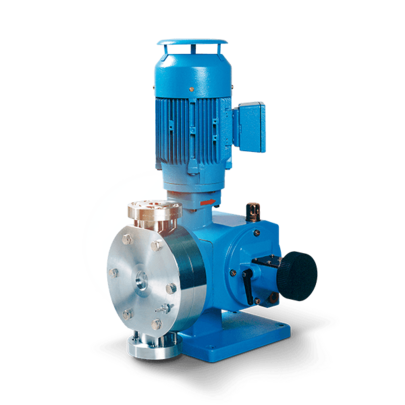

More DetailsLEWA ecosmart®: Diaphragm Metering Pumps

Experience the innovative LEWA ecosmart, a compact diaphragm metering pump offering multiplex capabilities at a competitive price. We assure the renowned LEWA quality, backed by our 70 years of market expertise. Choose LEWA ecosmart for smart metering pump solutions without compromising on quality or performance.

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

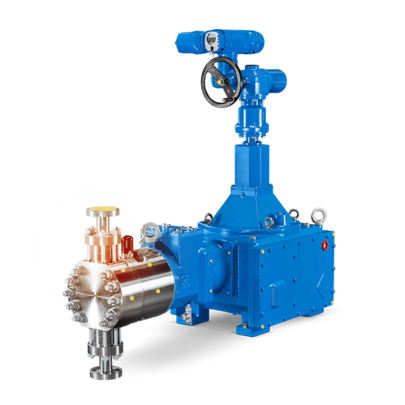

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

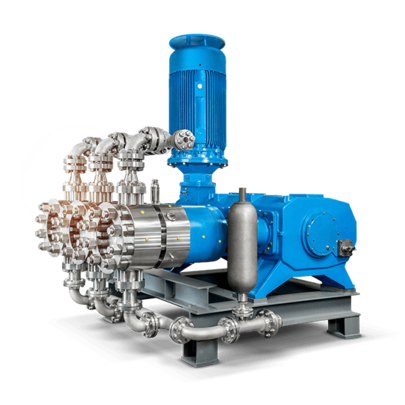

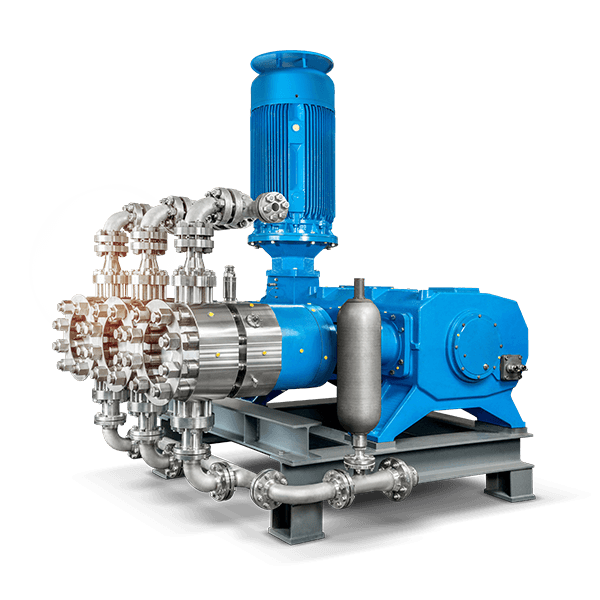

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

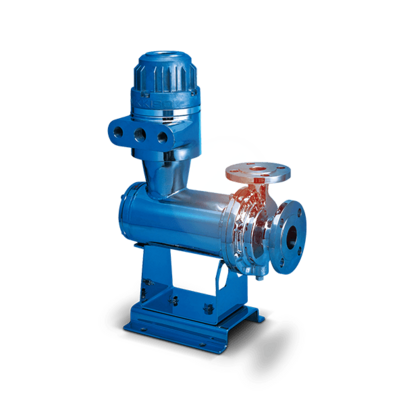

More DetailsNIKKISO NON-SEAL canned motor pump

The NIKKISO NON-SEAL canned motor pump has been designed specifically for the chemical industry. To do this, the centrifugal pump is designed in accordance with API 685.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details