Solutions

Above a daily consumption of 1,000 kg of LES, it is worth to calculate the amortization of a conversion to on-site dilution with the LES continuous blender from LEWA.

In this case a highly concentrated LES is purchased and then diluted to the desired process concentration and stored. Depending on daily consumption, the investment in a LEWA continuous blending system can be amortized within a few months.

The advantages of the LEWA continuous blending system are:

- Verifiable cost savings

- More flexibility in the production

- Individual selection of preservatives

- Low consumption of preservatives

- More independence

- Inventory keeps significantly longer

Two typical versions with/without LES continuous blender

LES (70% concentration), water, and an optional preservative are simultaneously conveyed, driven by pumps or differential pressure into the feed of a dynamic mixer and mixed. Synchronous control of the drive motors of the respective pumps ensures continuous uniform quality of the diluted solution via the flow monitoring.

The desired concentration as well as production output can be set using a control panel on the control cabinet on site, or optionally via remote signal.

Available system capacity: 1-15 t/h diluted LES.

Background

Sodium lauryl ether sulfate (LES) is an oil and fat soluble detergent.

Due to its foaming property, LES is used in many body hygiene products and as a fat solvent. For the production of these products, LES is mainly used in an initial concentration of 27%.

LES is usually obtained in the commercial concentration of 27%. When purchasing the pre-diluted surfactant, a large volume of diluting water is purchased as well, resulting in high transport costs.

LES can also be purchased with a 70% detergent substances content and, at the start of the process, diluted in a stirring tank to the desired concentration. This comes with additional time and energy expenditure and has a negative impact on system productivity.

Industries

Pumps and Systems for the Manufacture of Detergents and Cleaners

LEWA offers continually operating, formula-controlled systems for the manufacture of household and industrial cleaners in all commercially available surfactant concentrations – from raw product to end product. Contact our experts and let us advise you – we will work with you to configure pumps and systems for the manufacture of detergents and for the production of other cleaners.

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsProducts

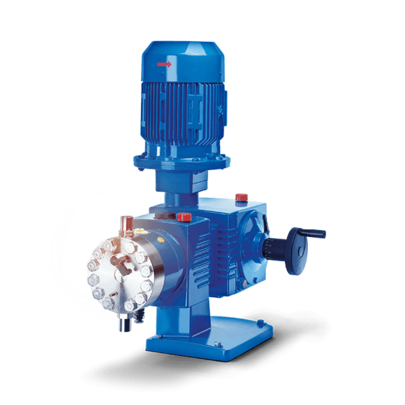

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

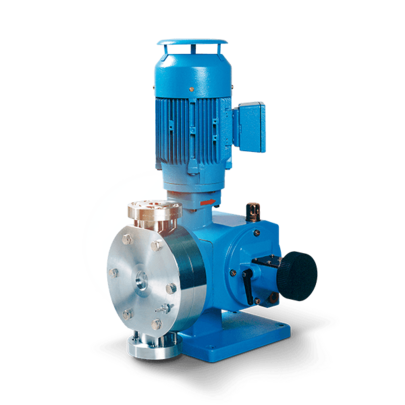

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

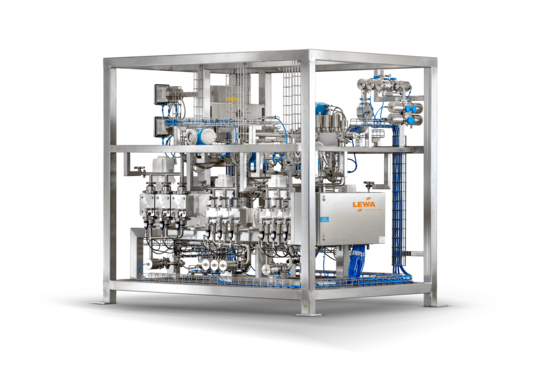

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsMunsch - Standardized NPC and NPC-B chemical pump

The armoured pumps of the NPC and NPC-B series are designed to meet chemical process industry standards and are ideally suited to pumping chemicals and solvents.

More DetailsMunsch - Standardized CM & CM-B Type chemical pump

Munsch CM/CM-B Type standardized chemical pumps with magnetic are designed to meet chemical process industry standards. Their hermetically sealed design makes them a safe pumping solution for problematic chemicals and solvents.

More DetailsMunsch CS/CS-B Standardized chemical pump

The CS/CS-B series armoured pumps meet the standards of the chemical process industry and are ideal for pumping chemicals and solvents. They are manufactured in a back pull-out design for easy maintenance.

More DetailsMunsch - Standardized chemical pump ECM & ECM-B

The armoured magnetically-coupled pumps of the ECM series are designed to meet chemical process industry standards. Their hermetically sealed design makes them a safe pumping solution for problematic chemicals and solvents.

More DetailsStandardized chemical pump NP and close-coupled chemical pump NP-B

The NP pump series is excellently suited to pumping tasks in the chemical industry, electroplating plants, metallurgical industries, steel and stainless steel pickling lines, evaporation and regeneration units, wet flue gas cleaning systems downstream of waste incinerators as well as in exhaust air scrubbing and industrial waste water treatment.

More DetailsChemical centrifugal pump NPC Mammut

The armoured pump is designed to meet chemical process industry standards and can handle high delivery rates and pump heads.

More DetailsVertical chemical pump TNP-KL

The type TNP-KL vertical chemical pump is specifically designed to pump acids, alkalis, chemically contaminated fluids, corrosive media and effluents - in the presence or in the absence of solids - directly from pump sumps, pump tanks, storage tanks or basins.

More DetailsMunsch - Vertical cantilever pump TPC and TPC-M

The heavy-duty type TPC and TPC-M vertical cantilever pump without bottom bearing is designed with run-dry capabilities to pump solids-carrying acids, alkalis and chemically contaminated effluents directly from pump sumps, pump tanks, storage tanks or basins.

More Details