Description

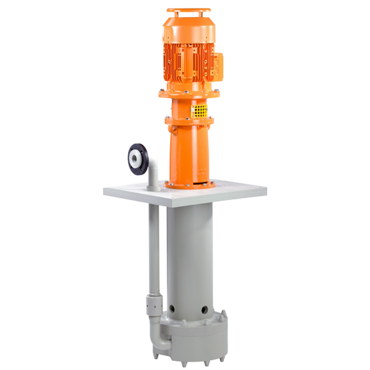

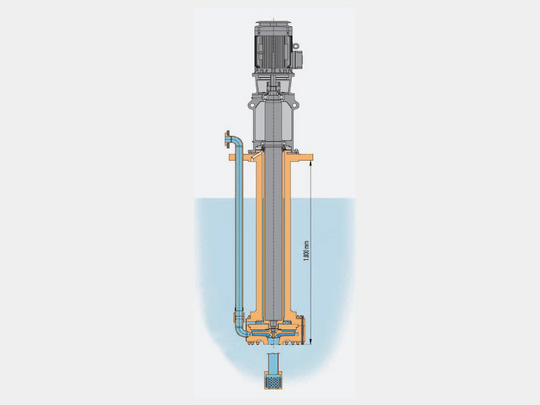

Vertical chemical pump TPC and TPC-M

The heavy-duty type TPC vertical cantilever pump without bottom bearing is designed with run-dry capabilities to pump solids-carrying acids, alkalis and chemically contaminated effluents directly from pump sumps, pump tanks, storage tanks or basins. The standard vertical setting depths of 1,000 and 1,800mm respectively can be extended to 3,400mm by a suction pipe.

Advantages

Numerically optimized hydraulics

The fluid dynamics of MUNSCH pumps are calculated, visualized and optimized using the latest numerical techniques (Computational Fluid Dynamics). The result is a hydraulic design with a virtually ideal flow profile.

This means:

- higher pump capacity at unchanged differential head

- reduced energy costs

- improved suction behaviour through low NPSH requirements

- minimized wear in abrasive service conditions

- reduced running noise

Reduced lifecycle cost

The numerically optimized hydraulic design is a key factor in minimizing the lifecycle costs of Munsch pumps. Capital and maintenance costs are reduced through the selection of the best suited hydraulic design and optimum motor sizes. Smaller cable cross-sections and lower-rated motor breakers keep down installation costs. The high pump efficiencies directly translate into energy savings.

The pump adapts to the task at hand – impeller designs

MUNSCH has the right impeller design for your specific pumping application. Wear, suction behaviour and efficiency are key factors determining the choice of the impeller. The right combination of impeller (hydraulics), material and shaft seal is all-decisive for a successful pump design and long service lives. MUNSCH pumps are available with closed, semi-open and vortex impellers.

Pump characteristic

Munsch chemical pumps feature a steep performance characteristic. This means that the pumps can be adjusted exactly to the operating point.

Options

- Set extendable depth via suction tube

- Suction filter

- Single plate according to customer specifications

- Suction side flange position and design, according to customer specifications

Technical Data

| Series | Pump capacity [Q] | Differential head [H] | Operating temperature [t] | Operating pressure [p] | Discharge nozzle | Motor rating |

|---|---|---|---|---|---|---|

| TPC | up to 600 m³/h | up to 65 m | from 0°C to +100 °C | up to 10 bar | DN 32 to DN 150 | up to 45kW |

| TPC-M | up to 250 m³/h | up to 65 m | from 0°C to +100 °C | up to 10 bar | DN 32 to DN 150 | up to 45kW |

Industries

Pumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsApplications

Additive metering for plastics

LEWA provides system solutions for metering additives for plastics. Ask our additive metering experts for more information!

More DetailsProduction of biodiesel

LEWA provides metering systems for producing biodiesel and other biofuels. Consult us!

More DetailsDilution of surfactants

Dilution of surfactants such as sodium lauryl ether sulfate (SLES) with LEWA pumps during production of detergents.

More Details