Cleaners and detergents

Precise, formula-controlled systems with LEWA

LEWA designs continuously operating, formula-controlled systems for manufacturing household and industrial cleaners, accommodating all commercially available surfactant concentrations—from raw material to finished product.

Surfactants, utilized as the main active ingredients, exhibit unique properties: each molecule features a hydrophobic and a hydrophilic end, making them essential in various applications. LEWA not only provides these systems but also supports the production and processing of surfactants. For more in-depth information, please refer to our Chemical Industry overview and the example application in Systems for Surfactant Processing.

LEWA Pumps and Systems In the Manufacture of Detergents and Cleaners

Our experts are readily available to provide support and guidance, collaborating with you to develop custom systems and plants tailored for manufacturing cleaners and detergents. With many years of industry expertise, you can trust LEWA to deliver high-quality solutions.

We place particular emphasis on the typical process steps involved in the manufacture of detergents and various other end products using LEWA pumps and systems.

| Example process steps | Examples of end products |

|---|---|

|

|

Solutions for the Manufacture of Cleaners and Detergents

We collaborate with you to design and implement fully automated, formula-controlled systems and support you in transitioning from batch to continuous processing in detergent production.

From concept development, engineering, and construction to the delivery of your detergent manufacturing system—including instrumentation, control systems, and automation—everything is provided by a single source.

Even after commissioning, LEWA continues to offer comprehensive services. We assist in process technology, providing support in process optimization, mechanical maintenance and repair, as well as in instrumentation and control technology.

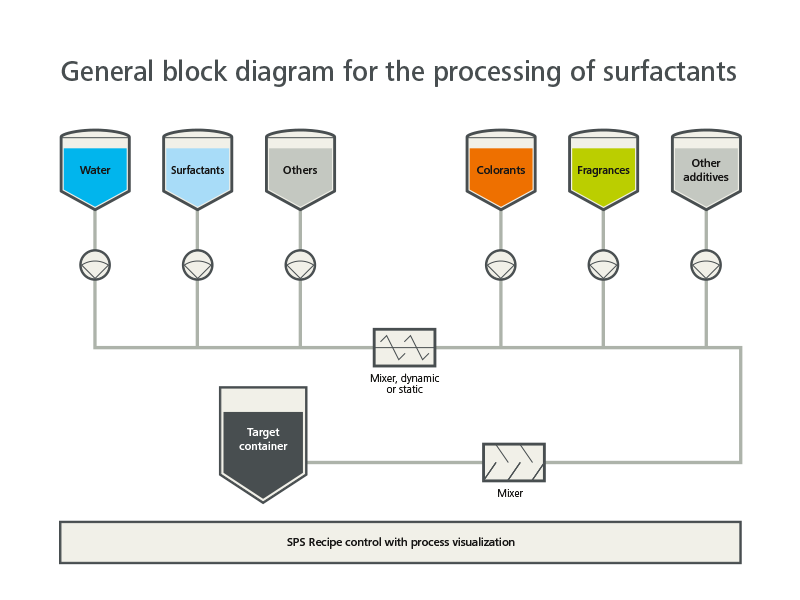

The accompanying diagram illustrates the basic setup of a surfactant processing system.

Advantages of the LEWA Pumps and Metering Packages for the Production of Cleaners & Detergents

High end pumps, equipment and systems

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.

Economic solutions

We always deliver economic pumps, systems and units with minimized energy consumption, high efficiency, low maintenance and a long lifetime.

Flexible application

High variability in operation in terms of pressure, temperature, flow rate and fluid properties with high metering accuracy guarantee a wide range of applications.

Tried and tested modular system

We design our systems and units in modular design with numerous engine and pump head combinations for different applications.

Special materials

On request, we can build systems with special materials such as Hastelloy, titanium, duplex stainless steel or further materials. If you are interested, please contact our product manager.

Patented sandwich diaphragm

Our patented diaphragm metering pumps use metal or PTFE sandwich diaphragms with Diaphragm Protection System (DPS) for maximum operational safety.

Easy to clean

An especially important advantage for pharmaceutical and food industry is that our systems can be quickly and easily cleaned with cleaning chemicals or hot steam.

International standards

LEWA pumps, systems and units are compliant with major international standards such as DVGW G280, WHG, PED, ISO 9001, ASME, ATEX and TA-Luft. Of course, you can also define your own standards.

Complete documentation

Receive supporting documents and certificates, including the operating instructions, as well as design and test details in different languages.

Applications

Fabric softeners

At LEWA, find out about plants and systems for fabric softener production. Our experts are happy to talk to you about your custom solution!

More DetailsCaustic soda production

At LEWA, find out about custom plants for producing and diluting different bases like caustic soda. Ask our experts for more information.

More DetailsChemical metering in high-pressure cleaning systems

LEWA metering and process diaphragm pumps meet the specific demands for the production of melamine (trimerization of urea). Consult us!

More DetailsDilution of surfactants

Dilution of surfactants such as sodium lauryl ether sulfate (SLES) with LEWA pumps during production of detergents.

More DetailsProducts

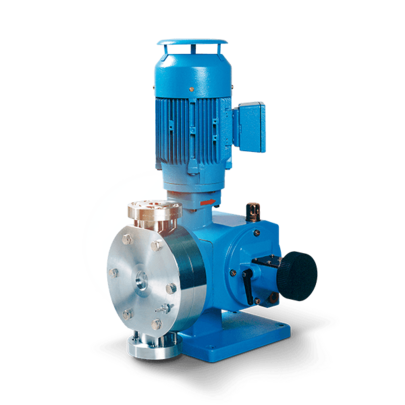

LEWA ecoflow® Diaphragm Metering Pump

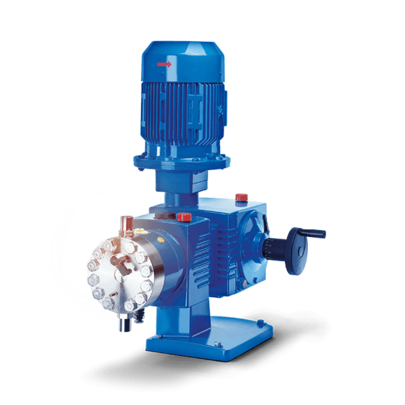

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecoflow® Packed Plunger Metering Pumps

Opt for the LEWA ecoflow packed plunger metering pump, a robust and reliable choice for hassle-free fluid metering. Available in multiple models to suit diverse processes, it's the metering pump trusted by industry leaders for consistent performance.

More DetailsLEWA ecosmart®: Diaphragm Metering Pumps

Experience the innovative LEWA ecosmart, a compact diaphragm metering pump offering multiplex capabilities at a competitive price. We assure the renowned LEWA quality, backed by our 70 years of market expertise. Choose LEWA ecosmart for smart metering pump solutions without compromising on quality or performance.

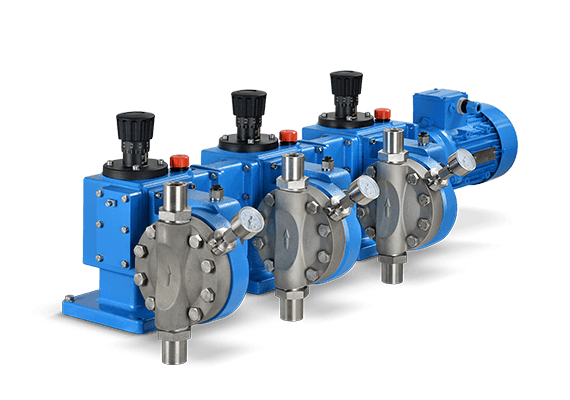

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

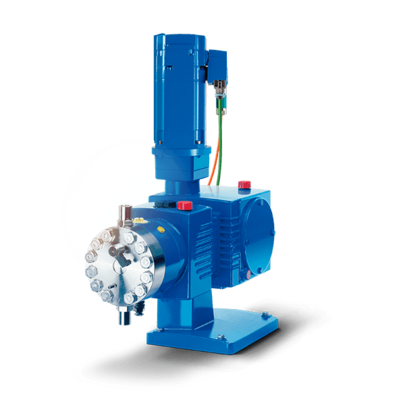

More DetailsLEWA intellidrive®:Mechatronic Diaphragm Metering Pump Technology

Customize both suction and discharge strokes to fit your precise specifications with the LEWA intellidrive® diaphragm metering pump. This technology allows you to individually shape pumping characteristics, ensuring optimal metering for your applications.

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

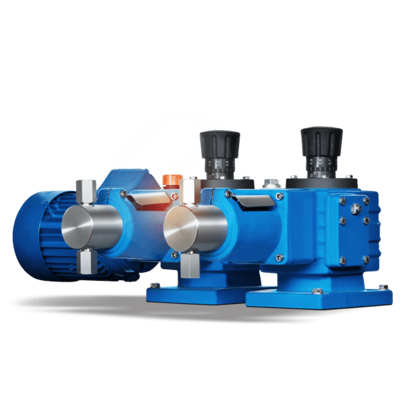

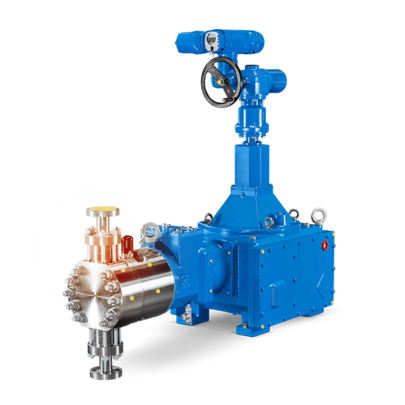

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More DetailsPomac rotary lobe pump

The flexible and economical positive-displacement pump for hygienic standard applications all the way to complex sterile applications with low-viscosity, viscous and/or shear-sensitive media.

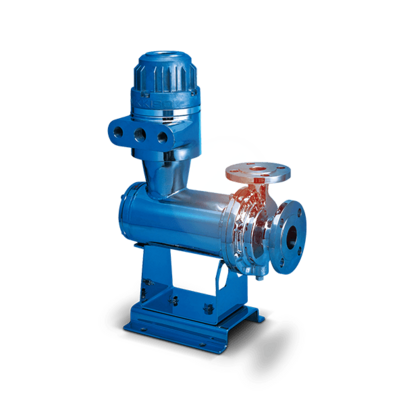

More DetailsNIKKISO NON-SEAL canned motor pump

The NIKKISO NON-SEAL canned motor pump has been designed specifically for the chemical industry. To do this, the centrifugal pump is designed in accordance with API 685.

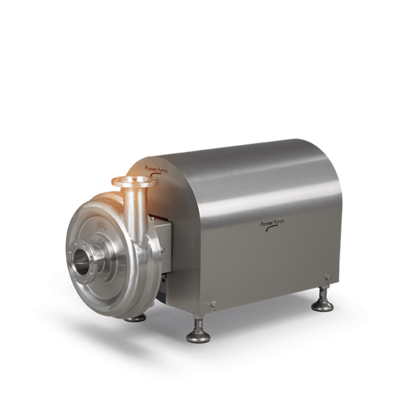

More DetailsPomac centrifugal pump

The stainless-steel Pomac centrifugal pumps for low-viscosity media feature optimum hydraulic data, a unique modular design and numerous options available in the area of shaft seals. It is available in various versions.

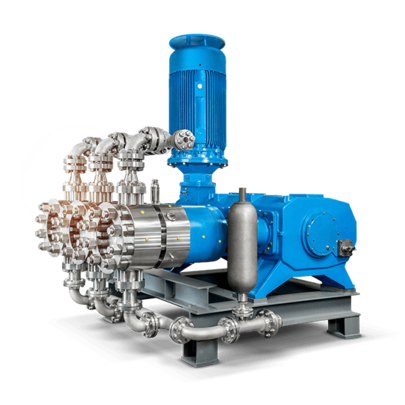

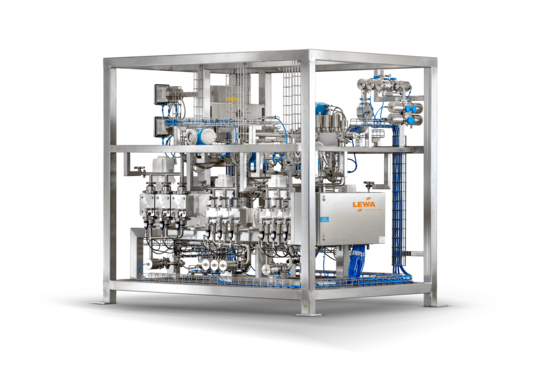

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details