Solutions for additive metering

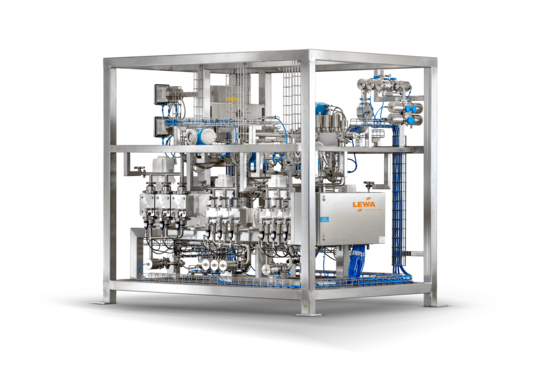

LEWA supplies complete, ready to use solutions fitting your application. All combinations of the LEWA modules offer a completely automatic, clean, reliable and flexible extrusion.

The scope of services ranges from the supply of system assemblies through engineering and the start up of complex metering and mixing systems with custom system control, process display, logging of operational data, as well as interfaces to the process control system. The scope, including the process control, is done from one source and guarantees the optimal safety and functionality of the system.

Advantages of LEWA heated systems:

- Suitable for all additives

- Costs for compounding and master batches are

reduced or even eliminated - Available in all control configurations

- Guaranteed reliable and flexible process by

the control/regulation of the mass flow - No deterioration of the additive by local overheating

- No coagulation due to cold spots

Operator and service friendly complete system:

- Clever arrangement and good accessibility of the piping

- Hinged locking doors that open wide

- Easy removal of side parts (service)

- Fine filters operated alternately, which can also be switched over externally during operation

Areas of application in additive metering

| LEWA metering systems process the following additives, for example: |

|---|

| Flame retardant |

| Sliding agents |

| Anti-fog agents |

| Anti-static agents |

| Lubricants |

| Wetting agents |

| Plasticizers |

| Anti-oxidation agents |

| Stabilizers |

Background information for additive metering

Extrusion is an important process in the plastics industry. Extruders must be heated, in order to melt the filled plastic granules or powder.

Some process related tasks make it necessary to cool the plasticized melt. Depending on the plastic used, other equipment is necessary, e.g., for pumping gases, which leave bubbles in the end product.

Normally other machines are required after the nozzle in the production of plastic products.

| They are subject to the following requirements: | In addition, there are the requirements for all raw materials: |

|---|---|

| Specific effectiveness | Good environmental compatibility |

| Lasting effect, e. g. for light stabilizers | Low health risks |

| High efficiency | |

| High stability | |

| No negative influences |

In general, the quantity used is very low and includes less than 1% of the total recipe.

Source: Wikipedia, February 2012

Industries

Pumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsProducts

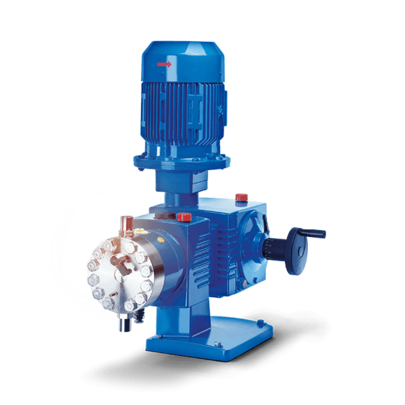

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecosmart®: Diaphragm Metering Pumps

Experience the innovative LEWA ecosmart, a compact diaphragm metering pump offering multiplex capabilities at a competitive price. We assure the renowned LEWA quality, backed by our 70 years of market expertise. Choose LEWA ecosmart for smart metering pump solutions without compromising on quality or performance.

More DetailsLEWA ecofoam® Blowing Agent Metering System

Redundantly designed, absolutely leak-proof system working in combination with extruders for metering various blowing agents in plastic production.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More DetailsMunsch - Vertical cantilever pump TPC and TPC-M

The heavy-duty type TPC and TPC-M vertical cantilever pump without bottom bearing is designed with run-dry capabilities to pump solids-carrying acids, alkalis and chemically contaminated effluents directly from pump sumps, pump tanks, storage tanks or basins.

More Details