Solutions

Advantages of LEWA process diaphragm pumps

- Hermetically tight (important for isocyanates)

- High working pressures are possible

- Suspension capability (nickel-raney catalyst)

- Safe in continuous operation

- Very high availability and reliability (optimized for continuous operation)

- Low life cycle costs

Source graphics/diagrams: www.fsk-vsv.de February 2012

Areas of application

Polyurethanes (PUR) belong to the most important polymers.

The technical area of application of PUR goes from "PUR soles" to "PUR foam". The main area of application of polyurethane is the use of foam, e.g., for upholstered furniture, mattresses, sponges, winter clothing, coating for carpets, constructional foam for thermal insulation, packing material, etc.

They are also used as paint and adhesives, as thermoplastic plastics for the production of rollers, rolls, and as elastomers and fibers, e.g. as elastane.

Industries

Chemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsProducts

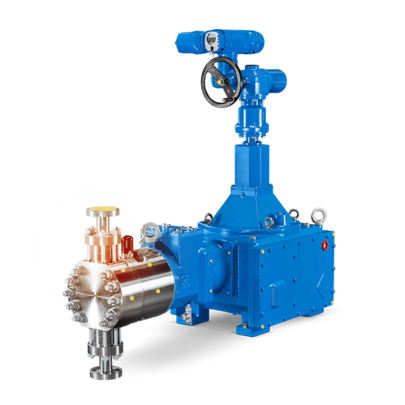

LEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

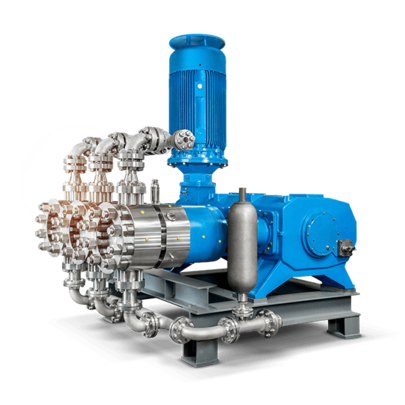

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More DetailsLEWA ecofoam® Blowing Agent Metering System

Redundantly designed, absolutely leak-proof system working in combination with extruders for metering various blowing agents in plastic production.

More Details