Solutions

Advantages of LEWA diaphragm metering pumps for pharmaceutical spray dryers:

- Hermetically sealed, no contaminants can get in or out

- Easy-to-clean design, easy accessibility for maintenance purposes

- High security thanks to 4-layer sandwich diaphragm with diaphragm monitoring and signaling without product contamination

- Clean operation – no particle abrasion in the LEWA pump

- Hygienic design, specially developed with and for the pharmaceutical industry (GMP-compliant)

- Coating of spray dryer nozzles with constant pressure through a rigid pump curve

- Gentle conveyance, no high shear forces

- Low hold-up in the pump head thanks to design with minimized dead space

- CIP; SIP; DIP

- FAT, SAT and global service

Options:

- Material 1.4435 (AISI 316L) with a surface roughness of Ra < 0.5µm

- Inert and FDA compliant construction materials

- Ex-proof protection, ATEX conformity

- According to ASME BPE

- Comprehensive documentation for qualification

LEWA is a member of leading committees for the hygienic design of pumps and systems.

QHD Certificate

Areas of application

LEWA metering pumps are used, for example, for:

- Aqueous solutions, suspensions and emulsions

- Compositions based on organic solvents, such as ethanol, isopropanol, acetone or methylene chloride

Filler, binder, disintegrants, sliding agents can thus be dissolved or suspended and transferred with the active material in defined, dry, free flowing, uniform particles.

Background

The fundamental concept of spray drying

The production of finely dispersed powder from a wet charging fluid by vaporizing the liquid:

- A solution /suspension is sprayed via nozzles or rotating disk atomizers into a hot air or nitrogen flow

- The supply to the spray drying system uses suitable pumps. Drying and particle formation are done simultaneously in the spraying process during this process. Due to these higher requirements on the pharmaceutical technology, the demands which are put on the bioavailability of a drug also increase. The effectiveness of a drug also depends on the generated particle size, after all.

Important customer requirements for this are:

- Particle size distribution

- Percentage of residual moisture

- Bulk density and particle shape

- Maintaining exact and consistent quality standards

- Precise, continuing, safe and

- low-pulsation fluid supply

Industries

Pumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsPumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsProducts

LEWA ecoflow®: Hygienic Diaphragm Metering Pumps

Discover the LEWA ecoflow® in its hygienic version, designed for sanitary applications. This versatile metering pump maintains its renowned all-around performance while meeting the stringent hygienic standards required in pharmaceutical and food production industries.

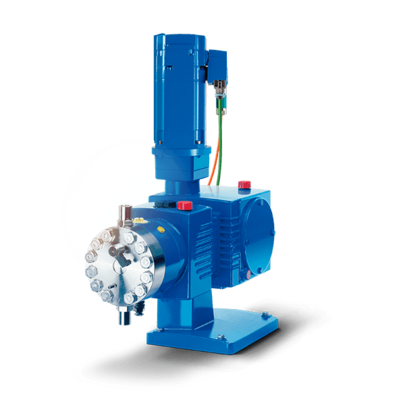

More DetailsLEWA ecodos®: Sanitary / Hygienic Diaphragm Metering Pumps

The LEWA ecodos is also offered in a sanitary/hygienic version, expertly meeting all operational standards for pharmaceutical and food production metering pumps.

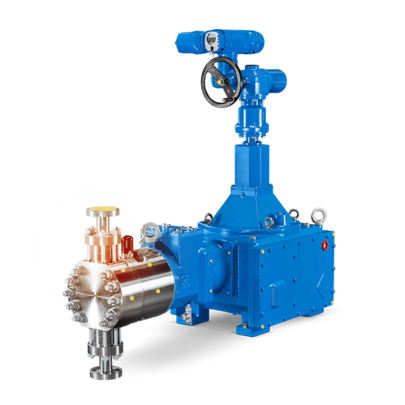

More DetailsLEWA intellidrive®:Mechatronic Diaphragm Metering Pump Technology

Customize both suction and discharge strokes to fit your precise specifications with the LEWA intellidrive® diaphragm metering pump. This technology allows you to individually shape pumping characteristics, ensuring optimal metering for your applications.

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

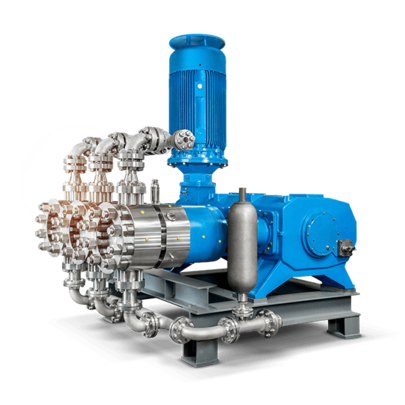

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

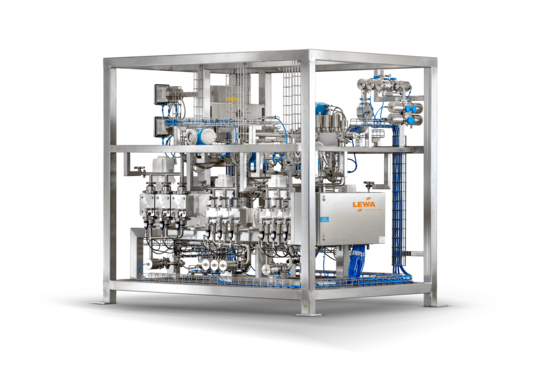

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More DetailsLEWA triplex®: High-Pressure Homogenizing Process Pumps

The LEWA triplex homogenizing pump utilizes hermetic diaphragm technology, making it ideal for sensitive applications such as ready-to-drink products, infant food, nutraceuticals, and enteral nutrition. Designed to handle demanding fluids, it finds optimal use in the food, beverage, and pharmaceutical industries.

More Details