Solutions for fabric softener production

Plant concept

Example: System control - Illustration of process step "surfactant dilution"

1. Features:

- Process control via PLC

- Central operation and monitoring of the process using control panel on the unit; user prompts and input using touch display

- Recipe management and creation using laboratory PC or plant PC

- Visualization of processes using logically connected graphic displays with overlaid operating messages, measured values and graphs

2. Equipment:

- Selection of tank design and sizes according to logistic data

- Tank accessories take into account the requirements for operation and system monitoring

- The right pump is selected and designed for each component to be metered

- Separate flow recording with continually measuring, highly precise flowmeters for each conveyor line

- Blending using dynamic and static mixers and, if necessary, mixing loops

- Sampling connections for quality monitoring

- Plate heat exchanger for temperature control

- Steam sterilization possible, creating the basic prerequisites in the closed system to render use of preservatives unnecessary

- Can be split on request for a master batch application/post finishing process

LEWA supplies the entire system from a single source:

Design, engineering, construction and delivery of the system, scope of service on request, complete with:

- Tank farm / storage containers

- Material transport from storage to the plant

- Temperature control

- Metering of individual components

- Mixing of components

- Cooling / total thermotechnical concept, if required

- Cleaning concept (CIP/SIP)

- Instrumentation

- Control system / automation

- Or any of these functional groups individually

- Selection of equipment in regards to material, dimensions, and quality to achieve an optimum cost/benefit ratio

- Consideration of specific on-site features in regard to layout planning, material flow, accessibility

- Consistent implementation of environmental protection requirements using the principles of "reduce, reuse, recycle" for both materials and energy

- Continuously operating system with the basic intention of introducing only the smallest possible quantities into the production process, avoiding losses when changing recipes or keeping them as low as possible

- Reduction of flushing agent quantities during the cleaning processes

- Recycling of product volume not conforming to specifications in the recycling process

- System operation only requires instruction on the operating system and main components of the system

The most important variables influencing pricing are:

- Degree of automation

- Scope and number of functional groups

- Scope of individual additional requirements

- Number of components and recipes

Background for fabric softener production

Process description

During the production of fabric softener, the concentrate, warm water, and thickener are blended in the first dynamic mixer. After the addition of cold water, the product passes through a static mixer and then through a heat exchanger for cooling. Then the "finishing components" are metered according to the recipe and the entire mixture is passed through another mixer.

Any product produced during start up and cleaning or when changing to another recipe and that cannot be used is discharged via a 3-way valve into a rework tank and added back into the process immediately or later, via a separate pump. Typical production units have production capacities starting at 5 tons/hr.

Industries

Pumps and Systems for the Manufacture of Detergents and Cleaners

LEWA offers continually operating, formula-controlled systems for the manufacture of household and industrial cleaners in all commercially available surfactant concentrations – from raw product to end product. Contact our experts and let us advise you – we will work with you to configure pumps and systems for the manufacture of detergents and for the production of other cleaners.

More DetailsProducts

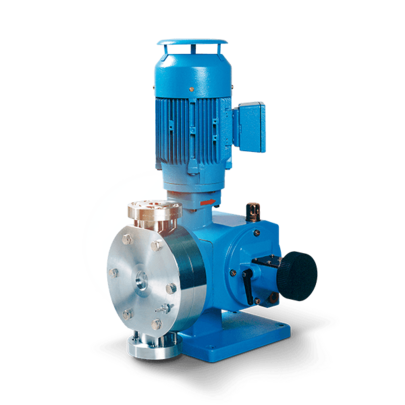

LEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

More DetailsPomac rotary lobe pump

The flexible and economical positive-displacement pump for hygienic standard applications all the way to complex sterile applications with low-viscosity, viscous and/or shear-sensitive media.

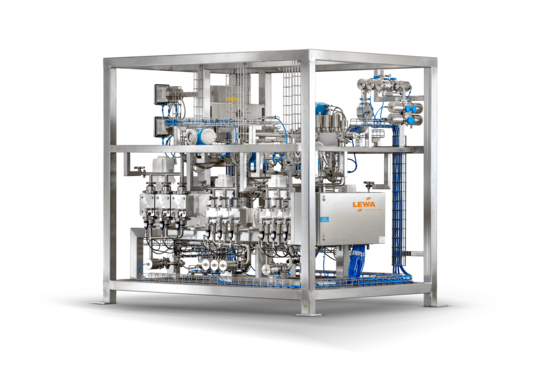

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details