Global Supply of Pumps and Packages for Onshore and Offshore Oil & Gas Industries

Optimized Solutions for Oil and Gas Industry Needs

Across the globe, the oil and gas production industry depends on LEWA for unmatched expertise and comprehensive operational solutions. Our diverse lineup, encompassing everything from cutting-edge antifouling agents to effective wax inhibitors, guarantees the secure and proficient handling of chemicals with our advanced pump systems and customized packaging options.

LEWA's pumps are meticulously designed for precision metering of essential substances like corrosion inhibitors and oxygen scavengers, as well as handling hazardous and aggressive chemicals, maintaining the utmost standards in process safety.

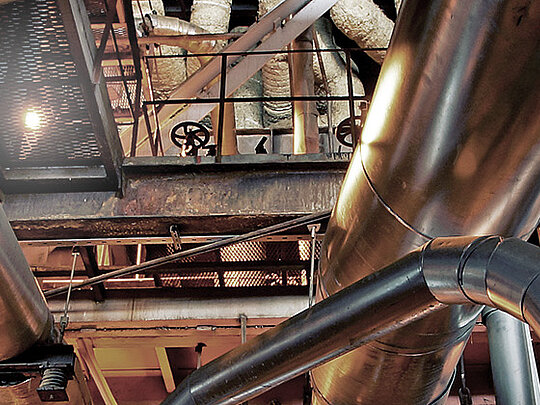

Furthermore, LEWA sets the benchmark for reliable high-pressure injection systems and pioneering sealless pump technology in the crude oil and natural gas sectors. Our robust systems are engineered to perform under the most demanding conditions — whether in the severe cold of Siberia, the extreme heat of the Middle Eastern deserts, or the unpredictable conditions at sea. Opt for LEWA for assured operational efficiency and secure performance for your oil and gas ventures, delivering peak productivity in any environment.

Key Applications for Pumps and Packages Across the Oil & Gas Industry

LEWA's specialized pumps and packaged systems are engineered for optimal performance in the oil and gas industries, facilitating the conveyance and advanced treatment of raw materials. Our products provide comprehensive solutions tailored to streamline every process in oil and gas production.

| Product applications | Chemicals | Purpose |

|---|---|---|

| Treating oil, gas, and water | Foam inhibitors | Reduce foam to ensure maximum flow rate |

| Asphalt inhibitors, antifouling agents | Prevent asphalt formation | |

| Biocides | Minimize the growth of aerobic and anaerobic bacteria | |

| Calcium nitrates | Prevent the formation of dissolved sulfides and H2S | |

| Corrosion inhibitors | Reduce corrosion in pipelines | |

| Demulsifiers, emulsion breakers | Split stable oil-water emulsions | |

| Oil separators/flocculants | Separate oil and production water | |

| Friction reducers, flow rate improvers | Reduce friction losses in pipelines | |

| H2S binders | Prevent corrosion by hydrogen sulfide | |

| Hypochlorites | Prevent the growth of organisms | |

| Hydrate inhibitors with low density/LDHI | Hydrate inhibitors with low metering rate | |

| Oxygen binders | Remove residual oxygen | |

| Paraffin inhibitors | Prevent paraffin formation | |

| PH control agents | Reduce glycol decomposition | |

| Polyelectrolytes | Filter aids | |

| Crust inhibitors, crust reducers | Prevent process equipment crusting | |

| Clarifiers for water | Remove oil particles in production water | |

| Wax inhibitors | Prevent wax formation | |

| Solar-powered systems for injecting chemicals | Corrosion inhibitors, methanol | Inject chemicals in remote and unmanned production sites or pipelines |

| Gas-powered systems for injecting chemicals | Corrosion inhibitors, methanol | Inject chemicals without emitting (acid) gas in remote or unmanned production sites or pipelines |

| High-pressure injection | Carbon dioxide CO2 | Injection underground |

| Hydrogen sulfide H2S | Injection underground | |

| Methanol/ethanol | Prevents the formation of hydrate in gas production sites | |

| Glycol (MEG/TEG) | Gas dehydration | |

| Sealless conveying | Condensate | Leak-free pumping of separated product with low feed pressure (high vapor pressure) |

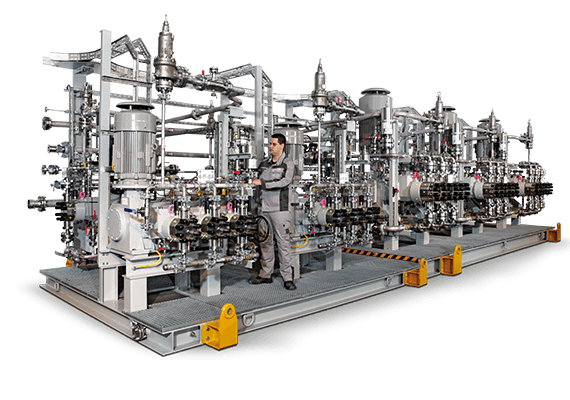

Integrated Pump and Package Solutions for Enhanced Oil & Gas Industry Operations

Choose LEWA for time-honored expertise in the oil and gas industry, delivering advanced pump and packaging equipment tailored for natural gas production. Our solutions surpass industry standards, offering EPC firms, operational teams, and end-users a comprehensive selection of superior-quality diaphragm and plunger pumps.

At LEWA, our custom-designed pumps cater to the specific demands of crude oil and natural gas extraction, aligning with industry benchmarks. We emphasize high-pressure functionality, hermetic sealing, and unmatched safety within a compact design. The innovation-driven LEWA pump head, with its robust PTFE diaphragm, can endure pressures of up to 1000 bar, epitomizing operational efficiency and cost savings.

With a history of expertise, LEWA stands out in global engineering and project management, guiding clients through each stage of their projects. For dependable and effective natural gas production solutions, LEWA is your trusted partner.

Key Benefits of Our Pumps and Packages for the Oil & Gas Industry Sector

High end pumps, equipment and systems

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.

Complete documentation

Receive supporting documents and certificates, including the operating instructions, as well as design and test details in different languages.

Global commissioning

With our global service network, we take your equipment into operation and provide technical service directly at your location - both onshore and offshore.

International standards

LEWA is ISO 9001 certified. Pumps, systems and units are compliant with all major international standards such as, API, ASME, TÜV and many more.

Calculation of fluid dynamics

When designing pumps and systems, we rely on computer-based calculations of the fluid dynamics in the pipelines and on appropriate integration of pulsation dampers.

Tests according to your specifications

Before starting up the system, we conduct well-documented test runs according to relevant international standards or to your specifications.

Flexible design

You can rely on over 60 years of experience in the design of pumps, systems and units: During the project phase, we respond flexibly to design changes or adjustments required.

Spare parts information in your language

You will get all available information about spare parts (including subcontractors) in your preferred language. Our spare parts service functions quickly and smoothly.

Certified welders

Highest quality and professionally trained staff: Welding jobs are performed by certified welders. On request, we install your system directly at your site.

Pump and Package Applications in the Oil and Gas Industries

Injection of corrosion inhibitor

Do you require systems for the injection of corrosion inhibitor? At LEWA, you can find expert consultation, detailed information and support!

More DetailsMethanol injection

Use skids and packages by LEWA for methanol injection in the oil and gas industry. Ask our experts for more information!

More DetailsCCS carbon capture and storage

Use LEWA process pumps for CCS (carbon capture & storage) processes and carry out the CO2 separation efficiently. We are happy to help.

More DetailsDisposal of hydrocarbon condensate

LEWA systems help you transport and dispose of hydrocarbon condensates (HCC) that arise when producing natural gas, both onshore and offshore.

More DetailsGas drying with glycol

LEWA provides reliable injection pumps and systems for gas drying with glycol. Ask our experts for more information today.

More DetailsInjection of demulsifiers

Injection of demulsifiers with LEWA packages in the oil and gas industry. We provide you with advice tailored to your application.

More DetailsSolar pump for onshore production

For more than 30 years LEWA has been providing autonomous chemical injection systems with solar-powered metering pumps.

More DetailsPigging technology and pig cleaning

LEWA offers packages for pigging applications in oil and gas industry. These packages are designed according to customers‘ requirements and are also available in explosion-proof design.

More DetailsProcessing of produced water

Produced water packages from LEWA can be used to purify produced water during oil drilling. They are hermetically sealed and have options for exact control.

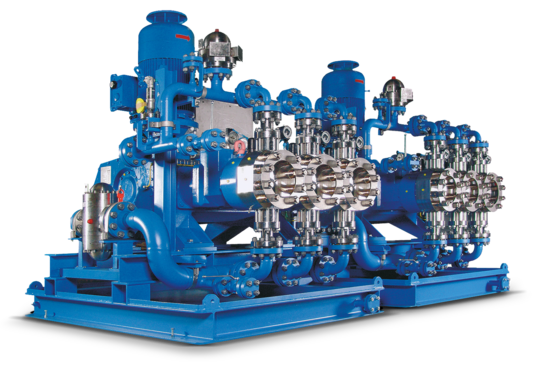

More DetailsLEWA’s biggest Chemical Injection Package

LEWA's biggest Chemical Injection Package includes 40 diaphragm pumps and has an estimated weight of 715 tons. Find out more about the record project!

More DetailsLPG fuel pumps for marine engines

LEWA offers robust and safe high-pressure diaphragm pumps for fuel gas supply systems on ships. Ask our experts for more information!

More DetailsProducts

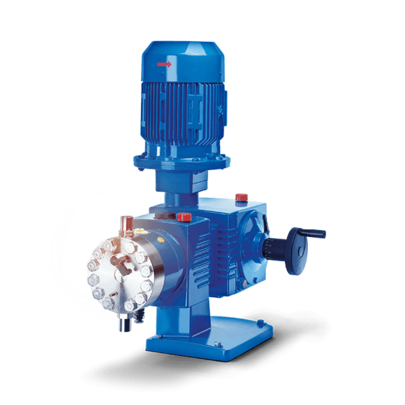

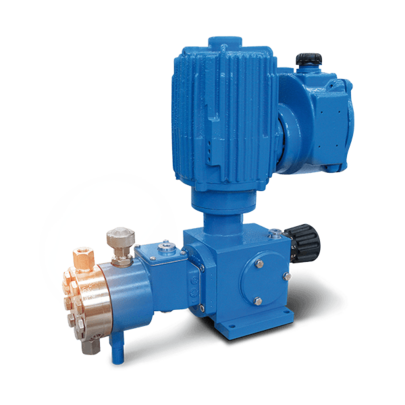

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecoflow® Packed Plunger Metering Pumps

Opt for the LEWA ecoflow packed plunger metering pump, a robust and reliable choice for hassle-free fluid metering. Available in multiple models to suit diverse processes, it's the metering pump trusted by industry leaders for consistent performance.

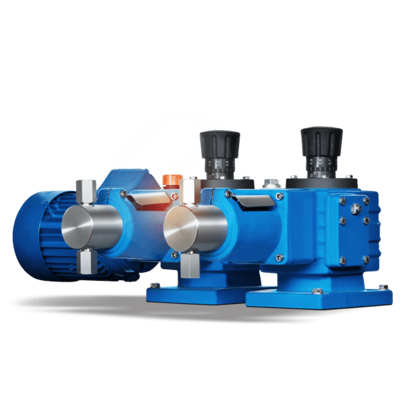

More DetailsLEWA ecosmart®: Diaphragm Metering Pumps

Experience the innovative LEWA ecosmart, a compact diaphragm metering pump offering multiplex capabilities at a competitive price. We assure the renowned LEWA quality, backed by our 70 years of market expertise. Choose LEWA ecosmart for smart metering pump solutions without compromising on quality or performance.

More DetailsLEWA MAH, MBH, MLM Series: Micro-Metering Pumps

Discover our metering pumps designed for ultra-low flow rates, offering an exceptionally cost-effective solution for proportional metering of fluid components to variable reference values. Ideal for precision applications.

More DetailsLEWA FC: High-Precision Laboratory Metering Pumps

Explore our precision metering pumps designed for micro-flow rates. The FC series, capable of handling pressures up to 400 bar, is tailor-made for laboratory and test center applications, offering unparalleled accuracy for small-scale fluid management.

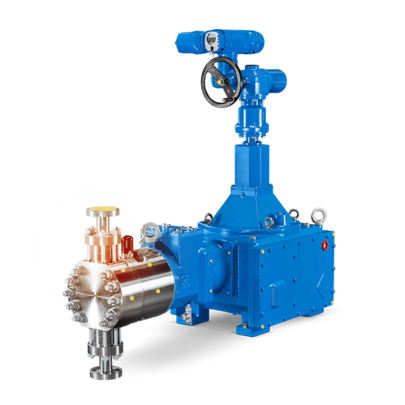

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

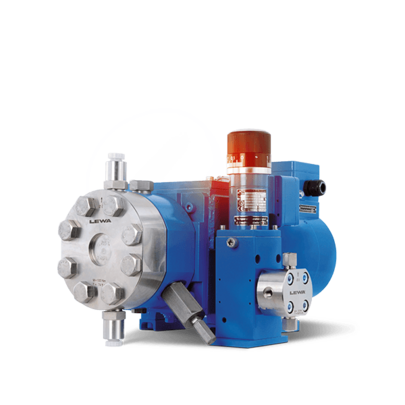

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More DetailsSundyne-Marelli horizontal and vertical process pumps

With flow rates as high as 8000 m³/h and a wide variety of different pump models, Sundyne-Marelli has a pump that will fit your application.

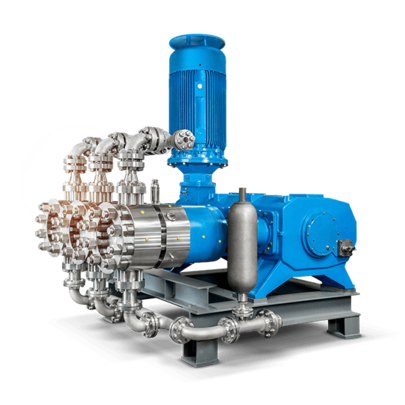

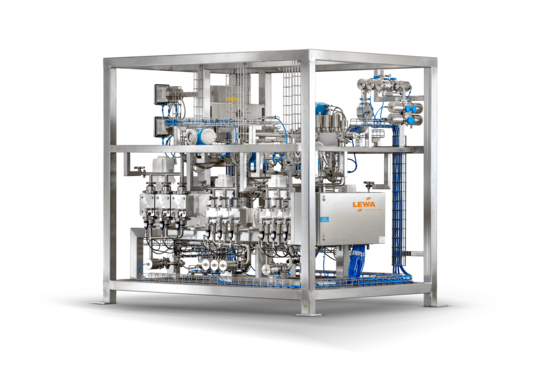

More DetailsLEWA Chemical Injection Packages

Developed and manufactured by the leading pump manufacturer. Customer-specific packages for chemical injection in the oil and gas industry.

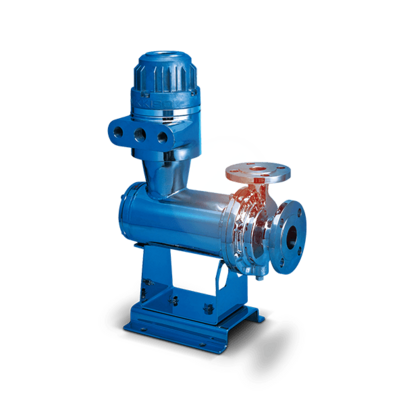

More DetailsNIKKISO NON-SEAL canned motor pump

The NIKKISO NON-SEAL canned motor pump has been designed specifically for the chemical industry. To do this, the centrifugal pump is designed in accordance with API 685.

More DetailsHMD Kontro sealless solenoid driven centrifugal pumps

HMD Kontro sealless solenoid driven centrifugal pumps are the first choice for handling toxic, aggressive, flammable, hazardous and high-value fluids. Protecting pumping fluid, people and the environment is particularly emphasized here.

More DetailsSundyne & Sunflo high-speed centrifugal pumps & compressors

Sundyne process pumps in accordance with ISO-13709, API-610 (OH5 OH6) and Sunflo pumps are the best choice for applications with high heads and small flow rates. The centrifugal pumps feature a simple design and consistent performance data.

More DetailsSundyne Ansimag sealless magnetically driven centrifugal pump

The sealless magnetically driven centrifugal pump Ansimag is simple in construction, but effective in use. All wetted parts are lined with ETFE. With the Ansimag pumps, it is possible to meter different types of fluids, even aggressive acids and solutions at temperatures up to 121 ° C. The Ansimag series meets the ASME / ANSI B73.3 standards for sealless magnetically driven centrifugal pumps.

More DetailsWilden standard air-operated diaphragm pump

As the inventor of the compressed air-operated double-diaphragm pump, Wilden Pump & Engineering Co. introduced the first pump of this design in 1955.

More DetailsLEWA Pump Skids

Ready-to-operate, custom-designed pump units with a small-footprint design. We choose all the pumps, materials, and accessories for these pump skids.

More DetailsLEWA Flow Distribution Systems (FDS)

With the help of LEWA Flow Distribution Systems and several Injection Rate Control Devices (IRCDs), a fluid can be metered to the process at several points.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More DetailsGeveke Nitrogen Generation Package

Complete package for continuous recovery of high purity nitrogen for oil and gas applications.

More Details