Solution

Advantages of diaphragm pumps in offshore applications:

- Absolutely resistant PTFE diaphragms

- Safe sandwich diaphragm with monitoring

- Hermetically tight, no leakage of toxic and environmentally polluting components

- Fast and easy diaphragm replacement

- No wetted piston sealing

- Diaphragm pump body made of resistant solid material

- Optimum valve layout using a modular system

- Service life of over 10,000 hours is normal

- Optimum lifetime with very low service costs

The stand-by pump can be started directly and remains switched on under suction or discharge pressure in the system.

Background

Onshore disposal is really not a problem because of the storage options. Offshore, HCC is separated from gas and intermediately stored in what are called knock-out drums. Reinjection or transport runs to a central collection point for further pumping onshore and for processing at the knock-out drums.

The quantity in this process is variable; pressure and availability are important aspects: The pump must withdraw a sufficient volume to avoid triggering the LSHH of the knock-out drum, since otherwise production must be stopped. The mixing of corrosive and abrasive contents means the selection of wetted parts is highly important, especially for valves that need matching hardness and corrosion resistance.

Important points for a proper layout:

- Design of the piping system

- Sizing of the piping system

- Filter data

- Pressure drop and mesh size (filter surface, double filter with switch-over and differential pressure display/signal)

- Shut-off valves with full area

- Pulsation damper and their installation location

- Position of the knock-out drum (over the pump, if possible, so that there is a feed)

In addition it includes the following substances:

- H2S: corrosive and highly toxic

- CO2: high vapor pressure, non-lubricating, freezes when decompressed

- Mercury: highly toxic and water contaminating

- Water, that is also separated from gas and combined with H2S is very corrosive

- Diesel portions (low): not dangerous, other than possible water contamination

- Water + H2SO4: acid, very corrosive

- Sand portions in HCC (low): highly abrasive in the predominant operating pressures up to 250/300 bar

The various components of HCC are listed in the table:

| HCC | Formula | Melting point °C | Boiling point °C | State at 25°C |

|---|---|---|---|---|

| Methane | CH4 | -183 | -164 | gaseous |

| Ethane | C2H6 | -183 | -89 | gaseous |

| Propane | C3H9 | -190 | -42 | gaseous |

| Butane | C4H10 | -138 | -0.5 | gaseous |

| Pentane | C5H12 | -130 | +36 | liquid |

| Hexane | C6H14 | -95 | +69 | liquid |

| Heptane | C7H16 | -91 | +98 | liquid |

| Octane | C8H18 | -57 | +125 | liquid |

| Nonane | C9H20 | -51 | +151 | liquid |

| Decane | C10H22 | -30 | +174 | liquid |

| Undecane | C11H24 | -25 | +196 | liquid |

| Dodecane | C12H26 | -10 | +216 | liquid |

| Eicosane | C12H42 | +37 | +343 | solid |

| Triacontane | C30H62 | +66 | +450 | solid |

Industries

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsProducts

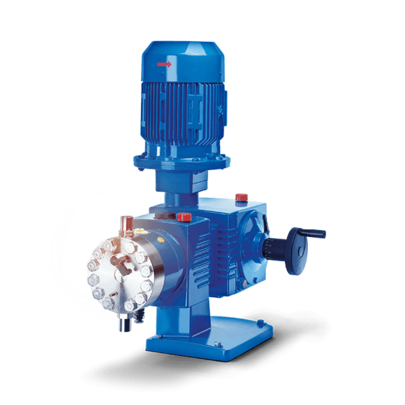

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

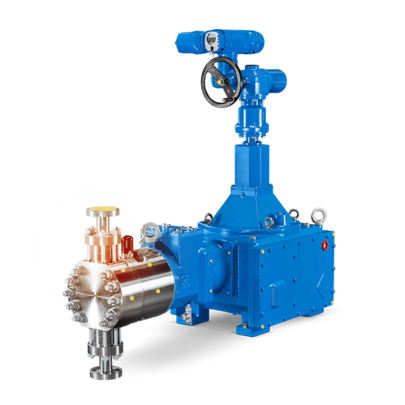

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

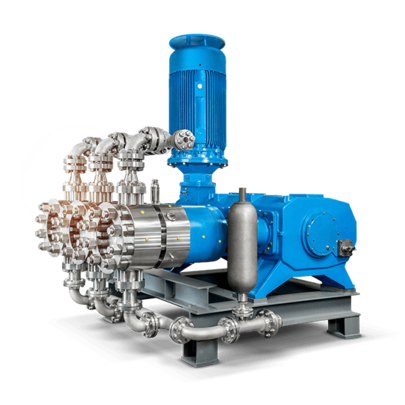

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More DetailsSundyne-Marelli horizontal and vertical process pumps

With flow rates as high as 8000 m³/h and a wide variety of different pump models, Sundyne-Marelli has a pump that will fit your application.

More DetailsSundyne & Sunflo high-speed centrifugal pumps & compressors

Sundyne process pumps in accordance with ISO-13709, API-610 (OH5 OH6) and Sunflo pumps are the best choice for applications with high heads and small flow rates. The centrifugal pumps feature a simple design and consistent performance data.

More Details