(copy 4)

Diaphragm pumps in oil and gas industry

Most applications in oil and gas industry run with diaphragm pumps. Their characteristics make them more suitable for the special requirements in this area than most other pump types. This whitepaper refers to several applications and devices in the oil and gas industry that are run with diaphragm pumps such as chemical injection packages.

Pulsation studies: Unsteady Friction Models in 1-dim CFD

The pump piping system has to be designed carefully if positive reciprocating displacement pumps with high hydraulic power are installed. Improper layout can lead to abnormal high-pressure pulsation, cavitation and fatigue failure of pump, piping or components. In this whitepaper, Dipl.-Phys. Marco Klinkigt (LEWA) explains the advantages of LEWA developed 1-dim CFD software. The software tools give us the opportunity to design an efficient pump-piping and dampener device layout for economic and reliable operation.

Safety Matters – How to implement a safety and environmental management system to reduce risks in cryogenic pump testing

LNG facilities are built with state-of-the-art equipment and safety controls. The industry’s highest priority has always been safety and security, which is reflected in its impressive safety record. NIKKISO Cryo’s cryogenic pump testing facility is utilized to provide performance and mechanical tests for submerged motor cryogenic pumps for engineering purposes for development, engineering tests for production and Factory Acceptance Tests (FAT) for customers. Furthermore, NIKKISO Cryo uses an integrated management system to improve quality, safety and environmental performance in a process and systems approach.

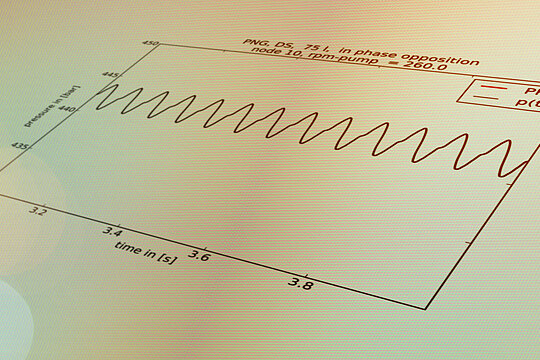

Pump Synchronization - Harmonization of osciliating pumps

LEWA pump synchronization is a technology that harmonizes oscillating pumps feeding the same piping system. This does more than just reduce pressure pulsation and vibrations in the piping. Synchronized operation of multiple pumps also makes it possible to add and remove individual pumps without changing the overall flow rate. As a result, various application scenarios are possible, such as flexible load distribution across multiple pumps or maintenance during ongoing operation.

More Energy efficiency for industrial pumps - Comparison and advantages

Industrial pump manufacturers are supposed to increase the energy efficiency of their technology by about 2.1 percent as well as substantially reduce the environmental impact—for example, caused by CO₂ emissions. In order to achieve this, it is advisable to consider a system comprehensively and compare the individual parameters of the respective pump type before deciding on a pump solution.

Condition Monitoring - Detect and avoid failures at an early stage.

Pump and plant availability are key factors for success in manufacturing companies. Production standstills mean sales losses. Due to more complex production systems and increasingly rigorous requirements for specific operator know-how, support from digital monitoring and analysis systems is necessary now in order to remain competitive in the future.

Production of biomolecules for pharmaceuticals - Diaphragm metering pumps prove their worth for critical mixing tasks in industrial oligonucleotide production.

Production facilities for the manufacture of oligonucleotides must be able to handle flammable, toxic compounds as well as meet hygienic standards to ensure biological integrity. Above all, however, they must be flexible and able to be scaled up from pilot plants so that they can ideally synthesize and purify a wide variety of drugs.