Crucial Pumps and Metering Systems for Crude Oil Distillation in Refineries

Distillation of crude oil with LEWA pumps, systems and plants

Refining crude oil demands meticulous cleaning, separation, and conversion processes to produce market-ready fuels such as gas, diesel, heating oil, lubricants, propane, and butane.

LEWA's role is pivotal in the intricate distillation stages within refineries, where precision and dependability are non-negotiable. With a global reach, LEWA provides not just advanced pumps and metering systems but also a robust support network of consultants and technicians for seamless installation and operational management of distillation plants.

Tailor-made to suit diverse operational demands, our proven pumps and metering systems are integral to refineries' metering infrastructure, ensuring that your project is up and running with optimal efficiency and tailored precision.

Pump and Metering System Applications in Crude Oil Distillation at Refineries

From extraction to the advanced refinement stages, LEWA's comprehensive range of products and systems provides integrated solutions for the entire spectrum of crude oil processing and refining.

The accompanying diagram details all vital refining operations, illustrating the breadth of applications for LEWA's custom-engineered plants and metering systems. For further details on optimizing your refinery's processes with our technology, our experts are ready to assist.

Benefits of LEWA Pumps and Metering Systems for Crude Oil Distillation in Refineries

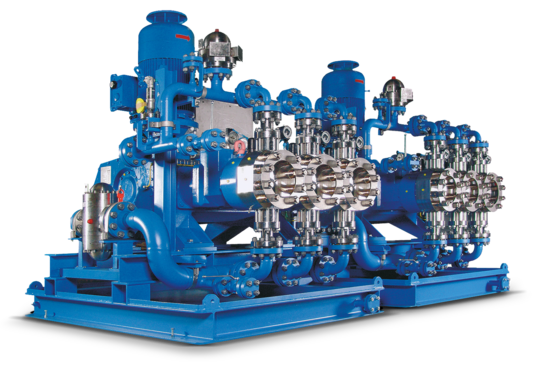

High end pumps, equipment and systems

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.

Complete documentation

Receive supporting documents and certificates, including the operating instructions, as well as design and test details in different languages.

Global commissioning

With our global service network, we take your equipment into operation and provide technical service directly at your location - both onshore and offshore.

International standards

LEWA is ISO 9001 certified. Pumps, systems and units are compliant with all major international standards such as, API, ASME, TÜV and many more.

Calculation of fluid dynamics

When designing pumps and systems, we rely on computer-based calculations of the fluid dynamics in the pipelines and on appropriate integration of pulsation dampers.

CAD-based engineering

Complete documentation: you will get CAD-based P&IDs as well as isometric drawings and construction plans of all pumps used in your system.

Flexible design

You can rely on over 60 years of experience in the design of pumps, systems and units: During the project phase, we respond flexibly to design changes or adjustments required.

Spare parts information in your language

You will get all available information about spare parts (including subcontractors) in your preferred language. Our spare parts service functions quickly and smoothly.

Tests according to your specifications

Before starting up the system, we conduct well-documented test runs according to relevant international standards or to your specifications.

Applications

Amine treatment

At LEWA, you receive pumps and systems for amine treatment in power plants. Ask our experts for more information.

More DetailsChemical metering in high-pressure cleaning systems

LEWA metering and process diaphragm pumps meet the specific demands for the production of melamine (trimerization of urea). Consult us!

More DetailsProduction of biodiesel

LEWA provides metering systems for producing biodiesel and other biofuels. Consult us!

More DetailsProduction of biofuels

Biofuels are produced using metering and process pumps from LEWA in the remote-head design. Learn more about these and other applications!

More DetailsCoal refinement with remote-head metering pumps in condensing systems

When coal is refined, it is ground as fine as dust and mixed into a suspension kept at a high temperature. LEWA metering pumps with a remote pump head are used for this.

More DetailsAdding antistatic agents to improve the conductivity of fuel

Antistatic additives or antistatic agents prevent the electrostatic charging of fuels which occurs due to the friction in the pipelines during transport. Use LEWA metering systems for this application!

More DetailsHydroconversion in refinery processes

With its remote-head metering pumps, LEWA offers the optimum solution for hydroconversion in refinery processes.

More DetailsProducts

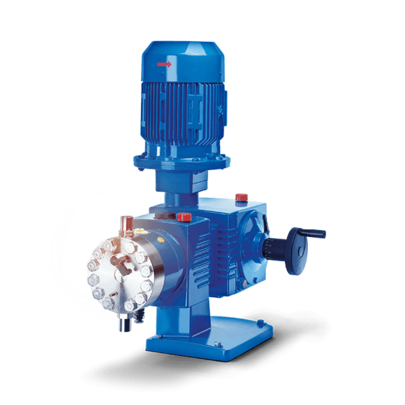

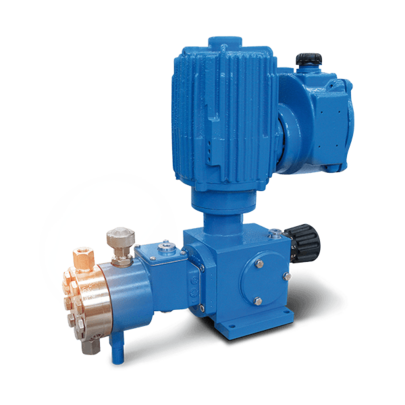

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecoflow® Packed Plunger Metering Pumps

Opt for the LEWA ecoflow packed plunger metering pump, a robust and reliable choice for hassle-free fluid metering. Available in multiple models to suit diverse processes, it's the metering pump trusted by industry leaders for consistent performance.

More DetailsLEWA ecosmart®: Diaphragm Metering Pumps

Experience the innovative LEWA ecosmart, a compact diaphragm metering pump offering multiplex capabilities at a competitive price. We assure the renowned LEWA quality, backed by our 70 years of market expertise. Choose LEWA ecosmart for smart metering pump solutions without compromising on quality or performance.

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

More DetailsLEWA MAH, MBH, MLM Series: Micro-Metering Pumps

Discover our metering pumps designed for ultra-low flow rates, offering an exceptionally cost-effective solution for proportional metering of fluid components to variable reference values. Ideal for precision applications.

More DetailsLEWA FC: High-Precision Laboratory Metering Pumps

Explore our precision metering pumps designed for micro-flow rates. The FC series, capable of handling pressures up to 400 bar, is tailor-made for laboratory and test center applications, offering unparalleled accuracy for small-scale fluid management.

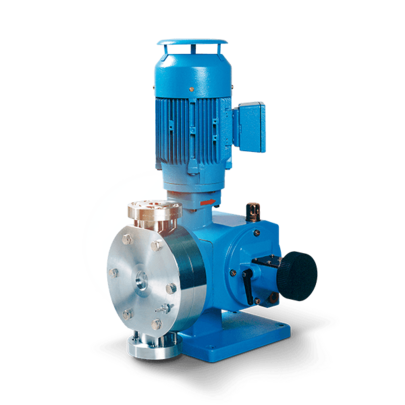

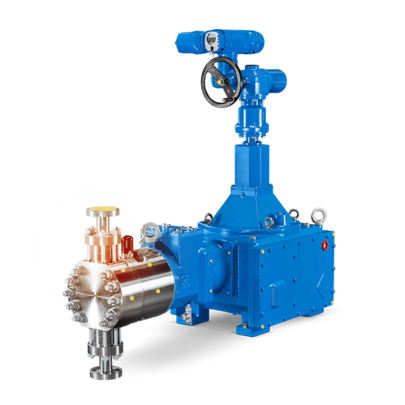

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

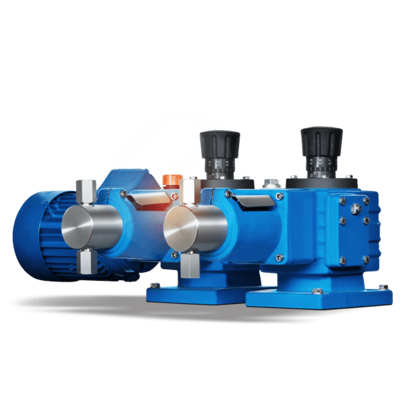

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

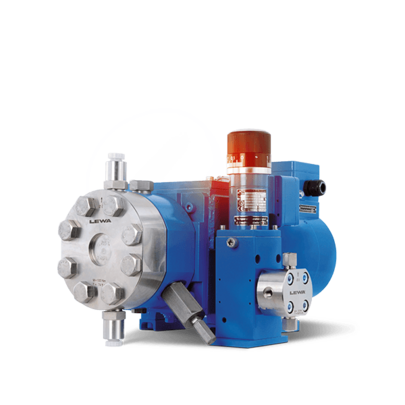

More DetailsLEWA Chemical Injection Packages

Developed and manufactured by the leading pump manufacturer. Customer-specific packages for chemical injection in the oil and gas industry.

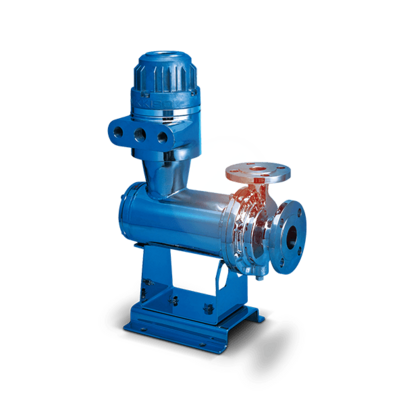

More DetailsNIKKISO NON-SEAL canned motor pump

The NIKKISO NON-SEAL canned motor pump has been designed specifically for the chemical industry. To do this, the centrifugal pump is designed in accordance with API 685.

More DetailsWilden standard air-operated diaphragm pump

As the inventor of the compressed air-operated double-diaphragm pump, Wilden Pump & Engineering Co. introduced the first pump of this design in 1955.

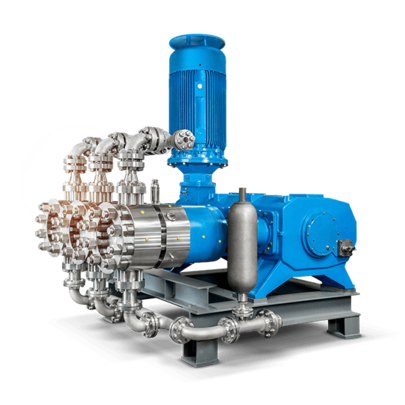

More DetailsLEWA Pump Skids

Ready-to-operate, custom-designed pump units with a small-footprint design. We choose all the pumps, materials, and accessories for these pump skids.

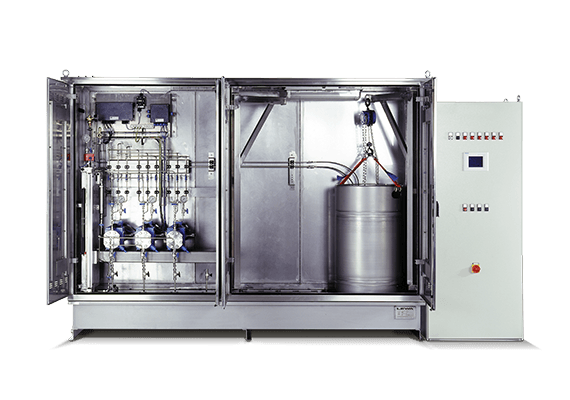

More DetailsLEWA Odorizing Systems

LEWA has been building odorizing systems for gases such as natural gas, oxygen, nitrogen, and carbon dioxide for more than 40 years. LEWA odorizing systems meter the odorant in question reliably, proportionally, and economically.

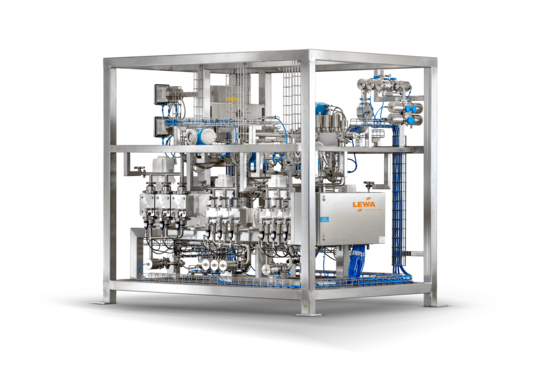

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More DetailsGeveke Nitrogen Generation Package

Complete package for continuous recovery of high purity nitrogen for oil and gas applications.

More Details