Solutions

LEWA ecoflow diaphragm metering pumps and LEWA triplex process diaphragm pumps in the remote-head design provide the following benefits for producing biofuels:

- Reliable operation thanks to spatial separation of the valve head and pump drive gear, which drives the displacement system

- Various options for the spatial separation: Depending on the maximum pressure, temperature and solids content, the valve head can be positioned geodetically higher or lower than the displacement system.

- Pressure-controlled opening and closing of the fluid valves in alternation forces the fluid in the valve head to move in only one direction in a pulsating flow.

- Pumps that operate with optimum thermodynamics enable the diaphragm pumps to be used at temperatures up to over 400 °C, which can arise when the biomass is processed in the high-pressure reactor.

- The hermetic seal of our pump technology ensures reliable conveyance of potentially hazardous, explosive or toxic substances that are necessary for the chemical reaction.

- The diaphragm pump with sandwich diaphragm made of pure PTFE guarantees process reliability with a long product life cycle.

- Depending on the properties of the biomass, processing with plunger pumps is also possible.

Background

How are BtL fuels produced?

BtL (biomass to liquid) fuels are synthetic fuels produced out of biomass. As part of the energy turnaround, the focus has moved to biofuels such as biodiesel, bioethanol and various synthetic fuels. Today, there are different pilot plants for the production of biofuels out of biomass in use. The first step in the production process of BtL fuels is the gasification of the biomass (pyrolysis). In a more or less heavy reacting thermal splitting at temperatures varying from 200 to more than 1000 °C, the chemical structure of the mass is modified. Long molecular chains split up due to the influence of heat. A synthesis gas is produced, which contains hydrocarbons with shorter molecular chains, carbon monoxide and dioxide as well as pure carbon and water vapor. The subsequent step is the synthesis: The synthesis gas is chemically processed, often by using the classic Fischer-Tropsch method.

As a result of this proceeding, different gaseous and liquid hydrocarbons remain, which are used as low-sulfur synthetic fuels in industry. The final products differ chemically from regular fuels like gasoline but still can be used in gasoline or diesel engines, and they can be distributed via already existing gas stations. BtL fuels are second generation biofuels. That means they can be made from a wider spectrum of raw materials than biodiesel or bioethanol. For example, cellulose-rich biomass like straw or wood can be used. Fuel yields per hectare could thus be increased. If slurry, waste wood, compost, dairy or natural waste from food services are used, there are fewer problems because of the scarcity of areas of cultivable land used for food crops and forages.

Source: Wikipedia.de; June, 2014

Industries

Pumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsProducts

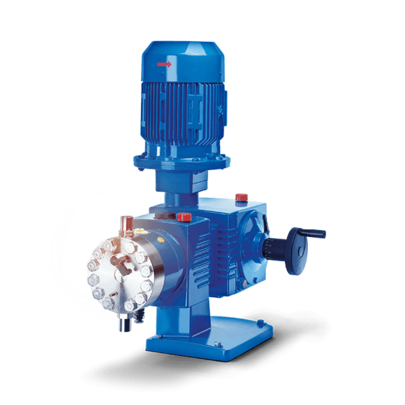

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

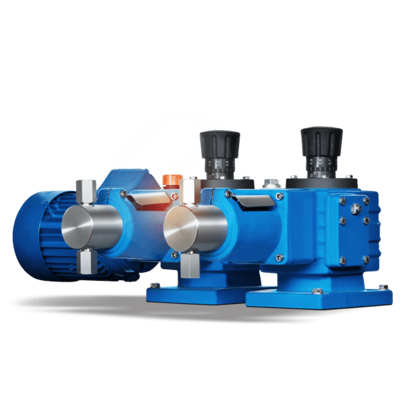

More DetailsLEWA ecoflow® Packed Plunger Metering Pumps

Opt for the LEWA ecoflow packed plunger metering pump, a robust and reliable choice for hassle-free fluid metering. Available in multiple models to suit diverse processes, it's the metering pump trusted by industry leaders for consistent performance.

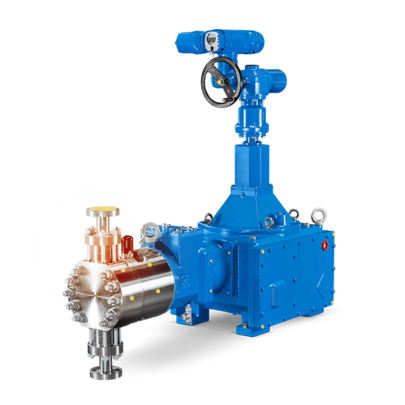

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

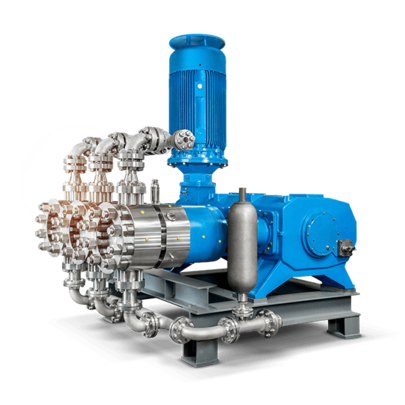

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

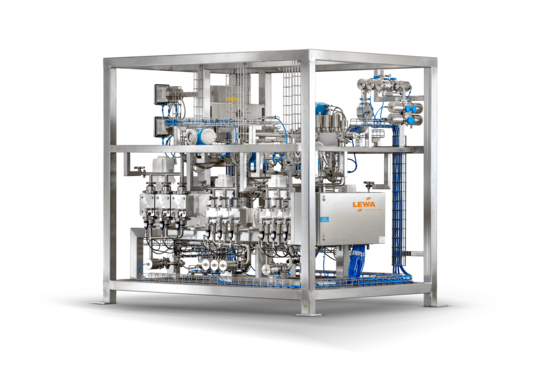

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details