Our customers are the focus of everything we do.

LEWA Solitions GmbH is your contact partner in Germany for metering pumps, process diaphragm pumps, odorizing systems, customer-specific metering systems, NIKKISO centrifugal canned motor pumps, pumps and fittings from Richter Chemie-Technik GmbH*, hygienic pumps from Pomac and Wilden air-double-diaphragm-pumps.

Ingenieurbüro Schmedding is a subsidiary of LEWA Solutions GmbH that is located in Erkrath, a town in the German state of North Rhine-Westphalia. Through this subsidiary, we are also able to offer you gear pumps from WITTE Pumps & Technology GmbH, Bungartz special centrifugal pumps, Hammelmann process plunger pumps and PFJ progressive cavity pumps. Get in touch with us! We would be happy to talk to you about your custom solution.

* Please contact us regarding availability in your region.

Facts LEWA Solutions GmbH

| About LEWA Solutions GmbH |

|---|

| Managed by: Eric Rottiers |

| Founded in: 2017 |

| Headquarters: Leonberg, Germany |

| Pump design in accordance with: Directive 2006/42/EC (Machinery Directive) Directive 2014/34/EU (ATEX) API 674 • API 675 |

| Hygiene certifications*: EHEDG • FDA • QHD |

| Memberships*: VDMA • Europump • Hydraulic Institute • ISPE |

| Your direct contact to LEWA Solutions GmbH | ||

|---|---|---|

Michael Klöpper, Ingenieurbüro Schmedding Niederlassung der LEWA Solutions GmbH Tel. +49 211 92485-0 Responsible for post code area: 32000-32839 33000-33829 44000-44899 45000-45771 45773-45999 46000-46699 47000-47279 48000-48739 49460-49549 57000-57500 59000-59969 | Heinz Woldering, LEWA Solutions GmbH Tel.: +49 4957-8996-15 Responsible for post code area: 20000-28999 29000-34999 37000-38999 48450-48469 48480-48484 48488-48489 49000-49469 49560-49999 | Ingo Dunker, LEWA Solutions GmbH Tel. +49 8742 422758 Responsible for post code area: 81000-87999 |

Eike Dylla, Ingenieurbüro Schmedding Niederlassung der LEWA Solutions GmbH Tel +49 211 92485-0 PLZ-Gebiete:41000-41537 41541-41999 45772 47819 47199 47226-47229 47239 47441-47929 | Alfred Marko, LEWA Solutions GmbH Tel. +49 6252 672900 Responsible for post code area: 64600-64689 64700-64759 66000-66990 67000-67169 67056 67200-67259 67320-67379 67400-67489 67600-67999 68000-68809 69000-69519 76000-76359 76600-76709 76710-76779 76800-76899 | Björn Pfizenmayer, LEWA Solutions GmbH Tel. +49 7452 60031-55 Responsible for post code area: 70000-74429 74700-74749 74800-74869 74870-74939 75008-75059 75100-75249 75300-75999 76400-76599 77000-79999 88000-89199 89200-89999 |

Kurt Mattis, Ingenieurbüro Schmedding Niederlassung der LEWA Solutions GmbH Tel +49 211 92485-0 PLZ-Gebiete: 41538-41540 50000-50999 52000-52539 53000-53399 53580-53613 53700-53949 | Markus Hillenbrand, Ingenieurbüro Schmedding Niederlassung der LEWA Solutions GmbH Tel: +49 211 92485-0 PLZ-Gebiete: 41000-41537 41541-41999 45772 47819 47199 47226-47229 47239 47441-47929 | Dirk Berger, LEWA Solutions GmbH Tel. +49 9572-603018 Responsible for post code area:34000-34999 36000-36999 74500-74699 90000-97799 97800-97859 97860-97959 97960-97999 |

Ingo Janßen, LEWA Solutions GmbH Tel. +49 172 7205754 Responsible for post code area: 20000-25999 29000-29999 27400-2769927711-27729 | Oliver Gall, LEWA Solutions GmbH Tel. +49 6405 502-119 Responsible for post code area: 35000-35799 53400-53579 54000-56999 57500-57649 60000-60549 61100-61389 63000-63699 63700-63939 64200-64297 64320-64331 64332-64589 64800-64859 65000-65939 67260-67319 67500-67599 | |

Industry Expertise

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsGas Odorization with LEWA Pumps and Metering Packages

Natural gas, oxygen, and nitrogen are odorless but potentially dangerous. This is why these gases are "odorized" with as strong a smelling substance as possible. For more than 40 years, LEWA has been developing systems for the odorization of gases such as natural gases, biogases, and liquefied gases. This process is enormously important, so the odorizing system has to operate precisely and reliably.

More DetailsPumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsPumps and Systems for the Manufacture of Detergents and Cleaners

LEWA offers continually operating, formula-controlled systems for the manufacture of household and industrial cleaners in all commercially available surfactant concentrations – from raw product to end product. Contact our experts and let us advise you – we will work with you to configure pumps and systems for the manufacture of detergents and for the production of other cleaners.

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsPumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsMetering Packages and Pumps for Power Plants and Power Suppliers

LEWA supports power plant operators and power suppliers with pumps and systems for conveying, metering, and mixing different fluids. We not only provide power plants with our products, but also develop solutions for wastewater treatment plants, gas bottlers, biogas producers, regional power suppliers, and hydrogen producers.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsPumping solutions for mining and metal and mineral processing

From the explosives manufacturing, ore extraction and metal and mineral recovery to effluents treatment and final product finishing, our solutions have helped our clients to save energy and consumables while keeping high operational safety and low cost of ownership.

More DetailsPartner Product brands

Pomac rotary lobe pump

The flexible and economical positive-displacement pump for hygienic standard applications all the way to complex sterile applications with low-viscosity, viscous and/or shear-sensitive media.

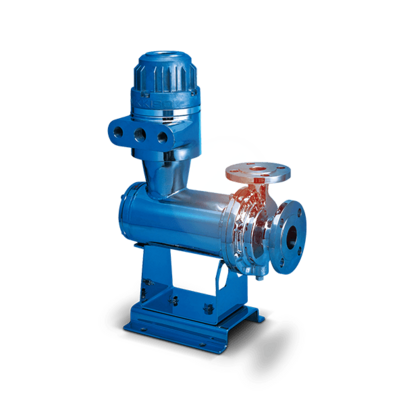

More DetailsNIKKISO NON-SEAL canned motor pump

The NIKKISO NON-SEAL canned motor pump has been designed specifically for the chemical industry. To do this, the centrifugal pump is designed in accordance with API 685.

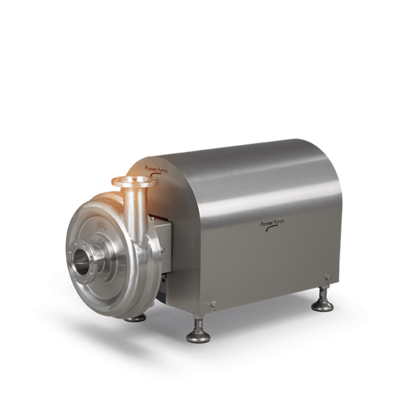

More DetailsPomac centrifugal pump

The stainless-steel Pomac centrifugal pumps for low-viscosity media feature optimum hydraulic data, a unique modular design and numerous options available in the area of shaft seals. It is available in various versions.

More DetailsRichter magnetic coupling and mechanical seal process pumps

The Richter centrifugal pump is particularly suited for pumping corrosive, hazardous or highly pure media and is qualified for medium and heavy working operating conditions. Numerous model versions complete the profile for various uses.

More DetailsWilden standard air-operated diaphragm pump

As the inventor of the compressed air-operated double-diaphragm pump, Wilden Pump & Engineering Co. introduced the first pump of this design in 1955.

More DetailsWilden sanitary/hygienic air operated diaphragm pump

Wilden's Saniflo FDA and Hygienic HS AODD pumps were developed to meet the highest standards and requirements in the industry.

More DetailsRichter shut-off, control, and safety valves

The Richter product range is practically seamless for corrosion-resistant shut-off, safety, sampling, check and sight-glass valves as well as control devices for control and shut-off tasks.

More Details