Energy Utilities

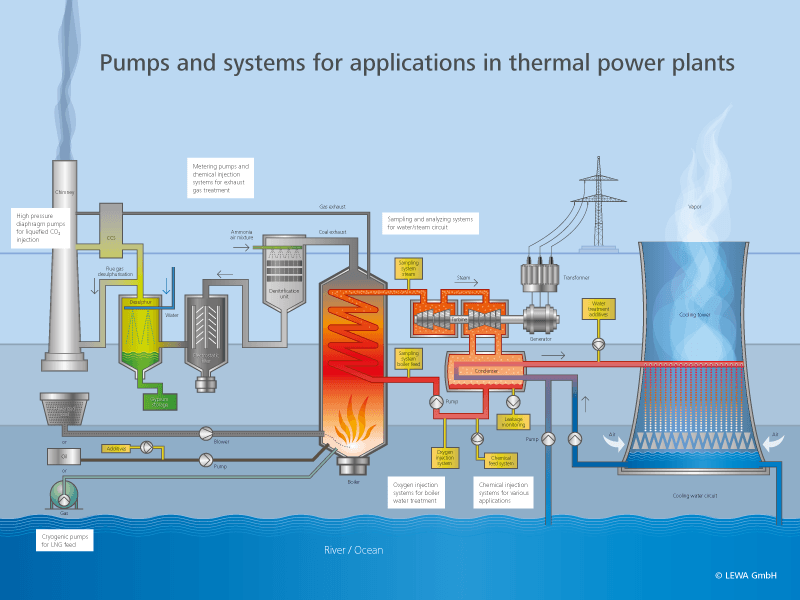

LEWA Pumps and Systems for Power Producers and Distributors

LEWA offers the world's most advanced diaphragm metering pumps, widely utilized across various applications in the energy utilities sector. If you're seeking a reliable pump solution for a power plant or require expert advice on energy utility system solutions, don’t hesitate to contact us and benefit from our seasoned experts’ guidance.

The energy utilities industry encompasses the essential processes of generating, transporting, distributing, and storing energy. Our clientele includes operators, suppliers, plant construction companies, and planners—all of whom have relied on our products and extensive industry knowledge for over 60 years. Since 2009, our product range has expanded to include Nikkiso's innovative offerings, such as cryogenic pumps and canned motor pumps.

Areas of Application for LEWA Pumps and Systems for the Energy Utilities Industry

The LEWA portfolio encompasses a diverse range of applications tailored to different customer segments within the energy utilities sector. We are eager to assist with your specific inquiries and further explore other potential applications. Our experts are dedicated to developing custom solutions tailored to your needs or designing the ideal pump system for your power plant.

| User segments | Typical applications for our customers |

|---|---|

| Fossil fuel power plants, thermal power plants, combined-cycle power plants |

|

| Biofuel producers (1st to 3rd generation) |

|

| Biogas producers |

|

| Battery manufacturers |

|

| Wastewater treatment plants |

|

| Gas bottle fillers |

|

| Catalyst manufacturers |

|

| Natural gas/vehicle gas filling stations |

|

| Ship yards, ship suppliers double-hulled tankers, LNG/LPG tankers gas terminals |

|

| Chemical plants Solar cell manufacturers |

|

| Public utility companies, regional power suppliers, and new energy companies |

|

| Hydrogen producers |

|

Solutions with LEWA Pumps and Systems for Energy Utilities

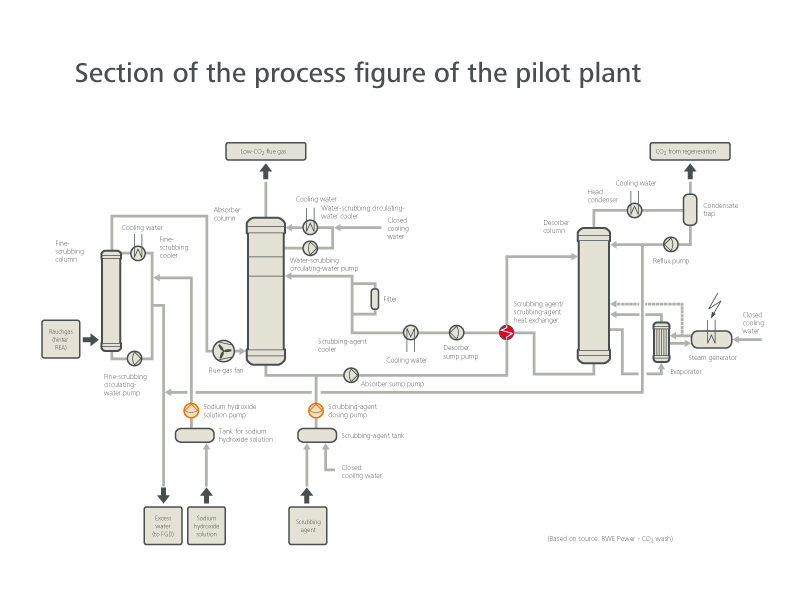

With 60 years of experience in the energy utilities industry, LEWA has developed expertise in a vast array of applications, enabling us to provide you with specialized metering pumps and customized pump solutions for power plants. Beyond individual pumps, we design, build, and deliver complete system solutions.

Our in-depth knowledge extends to pulsation effects and the behavior of various fluids, not just within pumps, but also in pipelines and systems.

Measurement, instrumentation, and control technology have been key components of the LEWA portfolio for over 40 years. Additionally, LEWA plays a significant role in various energy transition projects, such as biofuel production, biogas odorization, and thermal solar power plant circulation systems. Our pioneering expertise in CO2 handling further sets us apart.

Leveraging decades of experience, LEWA offers comprehensive international engineering and project expertise, supporting you throughout all project phases.

We work with you to develop the ideal solution that meets your expectations exactly, e.g., a pump for use in a power plant.

In particular, we can offer you:

- A comprehensive knowledge base in diverse applications

- Fluid evaluation and pipeline inspections

- Detailed engineering and global project management

- Globally leading pump technologies for maximum safety and cost-effectiveness

- Compliance with international standards such as DVGW G280, WHG, pressure equipment directives, ISO 9001, ASME, GOST-R, ATEX, TA-Luft (German Technical Instructions on Air Quality Control)

- Compliance with special power plant regulations and the preparation of comprehensive documentation when integrating a new pump into your power plant

- Commissioning, on-site training, and spare parts service

- Maintenance, repair, retrofitting, and global services for optimizing your systems

Advantages of the LEWA Pumps and Metering Packages for Energy Utilities

High end pumps, equipment and systems

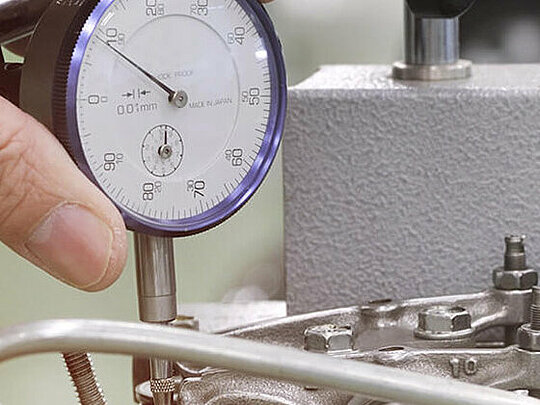

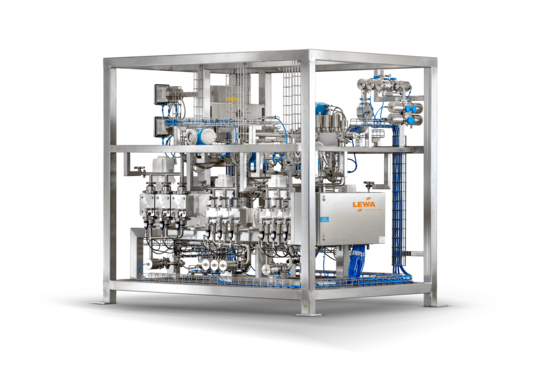

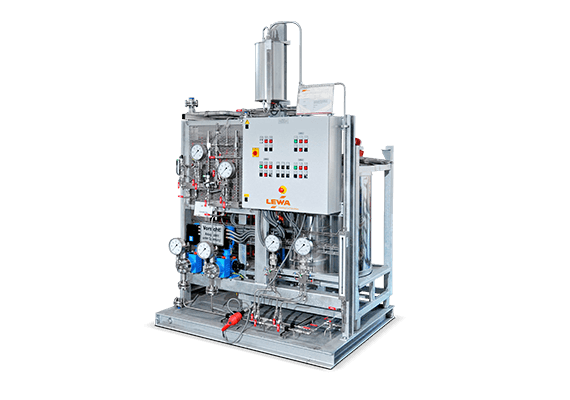

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.

Economic solutions

We always deliver economic pumps, systems and units with minimized energy consumption, high efficiency, low maintenance and a long lifetime.

Tried and tested modular system

We design our systems and units in modular design with numerous engine and pump head combinations for different applications.

Special materials

On request, we can build systems with special materials such as Hastelloy, titanium, duplex stainless steel or further materials. If you are interested, please contact our product manager.

Patented sandwich diaphragm

Our patented diaphragm metering pumps use metal or PTFE sandwich diaphragms with Diaphragm Protection System (DPS) for maximum operational safety.

Flexible design

You can rely on over 60 years of experience in the design of pumps, systems and units: During the project phase, we respond flexibly to design changes or adjustments required.

Global commissioning

With our global service network, we take your equipment into operation and provide technical service directly at your location - both onshore and offshore.

Complete documentation

Receive supporting documents and certificates, including the operating instructions, as well as design and test details in different languages.

International standards

LEWA pumps, systems and units are compliant with major international standards such as DVGW G280, WHG, PED, ISO 9001, ASME, ATEX and TA-Luft. Of course, you can also define your own standards.

Applications

Downstream processing

LEWA systems and gradient mixers are used in downstream processing of chemicals and biotechnology. We look forward to receiving your inquiry!

More DetailsProduction of biodiesel

LEWA provides metering systems for producing biodiesel and other biofuels. Consult us!

More DetailsFlue gas cleaning by means of metering sulfur | LEWA

When using an electrofilter for flue gas cleaning, metering sulfur improves the filtration efficiency. LEWA has the solution!

More DetailsAutonomous energy utilities

Supplying energy to production plants in remote areas of application is often difficult. Ensure an autonomous fuel supply with diaphragm pumps.

More DetailsContinuous metering of extremely small quantities with LEWA intellidrive

Minimum flow rates down to 1 ml/h: With LEWA intellidrive technology, we already have created solutions for many applications with very small flow rates.

More DetailsGas odorization in the natural gas distribution grid

At hubs in the gas distribution network, big amounts of natural gas are forwarded. LEWA odorization unit OD 4200 is able to odorize gas amounts of up to 1.000.000 m³/h.

More DetailsProducts

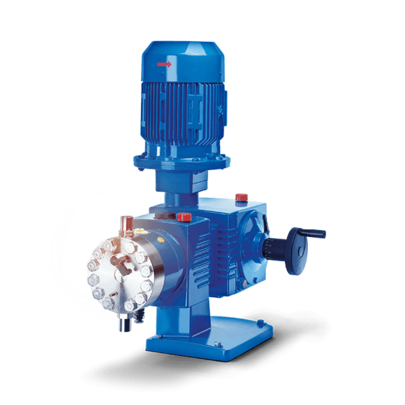

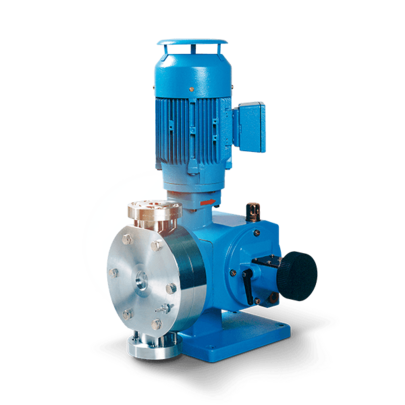

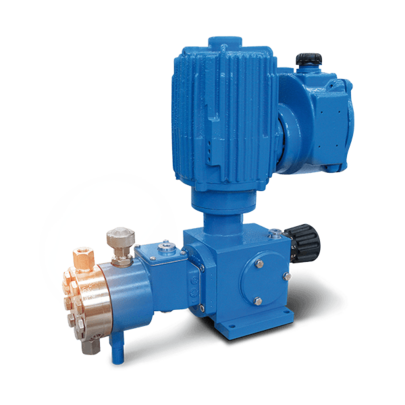

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecoflow® Packed Plunger Metering Pumps

Opt for the LEWA ecoflow packed plunger metering pump, a robust and reliable choice for hassle-free fluid metering. Available in multiple models to suit diverse processes, it's the metering pump trusted by industry leaders for consistent performance.

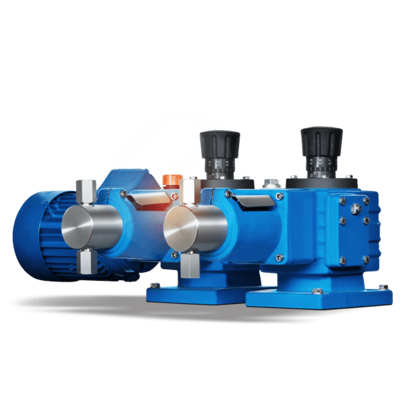

More DetailsLEWA ecosmart®: Diaphragm Metering Pumps

Experience the innovative LEWA ecosmart, a compact diaphragm metering pump offering multiplex capabilities at a competitive price. We assure the renowned LEWA quality, backed by our 70 years of market expertise. Choose LEWA ecosmart for smart metering pump solutions without compromising on quality or performance.

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

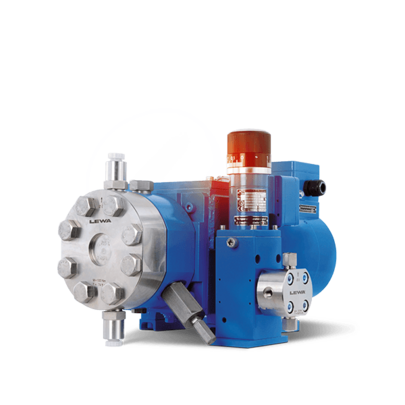

More DetailsLEWA intellidrive®:Mechatronic Diaphragm Metering Pump Technology

Customize both suction and discharge strokes to fit your precise specifications with the LEWA intellidrive® diaphragm metering pump. This technology allows you to individually shape pumping characteristics, ensuring optimal metering for your applications.

More DetailsLEWA MAH, MBH, MLM Series: Micro-Metering Pumps

Discover our metering pumps designed for ultra-low flow rates, offering an exceptionally cost-effective solution for proportional metering of fluid components to variable reference values. Ideal for precision applications.

More DetailsLEWA FC: High-Precision Laboratory Metering Pumps

Explore our precision metering pumps designed for micro-flow rates. The FC series, capable of handling pressures up to 400 bar, is tailor-made for laboratory and test center applications, offering unparalleled accuracy for small-scale fluid management.

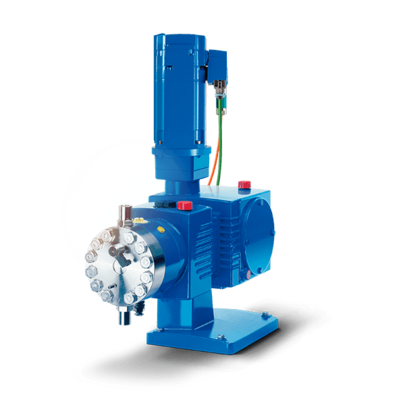

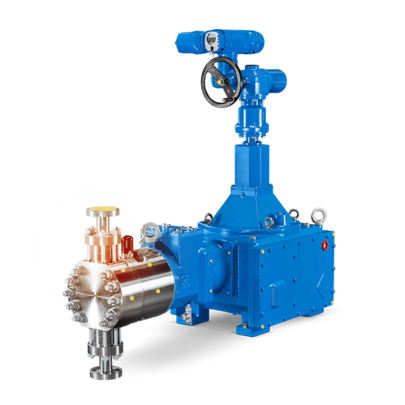

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

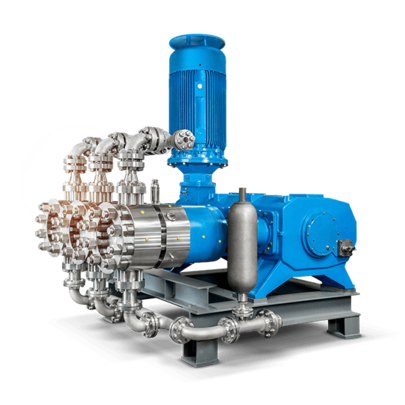

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More DetailsSundyne-Marelli horizontal and vertical process pumps

With flow rates as high as 8000 m³/h and a wide variety of different pump models, Sundyne-Marelli has a pump that will fit your application.

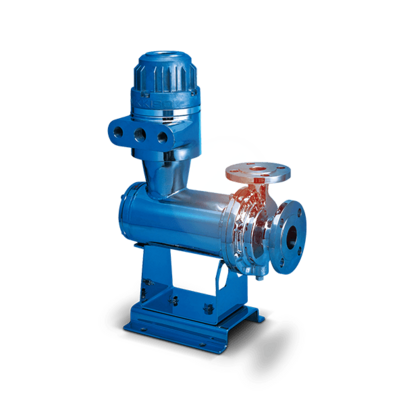

More DetailsNIKKISO NON-SEAL canned motor pump

The NIKKISO NON-SEAL canned motor pump has been designed specifically for the chemical industry. To do this, the centrifugal pump is designed in accordance with API 685.

More DetailsHMD Kontro sealless solenoid driven centrifugal pumps

HMD Kontro sealless solenoid driven centrifugal pumps are the first choice for handling toxic, aggressive, flammable, hazardous and high-value fluids. Protecting pumping fluid, people and the environment is particularly emphasized here.

More DetailsSundyne & Sunflo high-speed centrifugal pumps & compressors

Sundyne process pumps in accordance with ISO-13709, API-610 (OH5 OH6) and Sunflo pumps are the best choice for applications with high heads and small flow rates. The centrifugal pumps feature a simple design and consistent performance data.

More DetailsWernert horizontal and vertical plastic-lined centrifugal pumps

Wernert plastic-lined centrifugal pumps in process design are ideal for pumping corrosive, aggressive, toxic and abrasive fluids. Using the flexible pumping material, the centrifugal pump can be designed for various applications.

More DetailsWilden standard air-operated diaphragm pump

As the inventor of the compressed air-operated double-diaphragm pump, Wilden Pump & Engineering Co. introduced the first pump of this design in 1955.

More DetailsLEWA Odorizing Systems

LEWA has been building odorizing systems for gases such as natural gas, oxygen, nitrogen, and carbon dioxide for more than 40 years. LEWA odorizing systems meter the odorant in question reliably, proportionally, and economically.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details