Solution

Metering silanes with LEWA systems has the following advantages:

- Closed and weatherproof systems for outdoor installation (frost and rain proof)

- Open system for indoor installation (stationary or mobile)

- Safe for installation in ex-zone

- System can be adjusted to supply voltage, system hierarchy as well as metering quantity and pressure

- System is adapted to meet requirements regarding flammability, toxicity, and corrosiveness of various silane types. (Already metered silanes include: trichlorosilane, tetrachlorosilane, vinyltrimethoxysilane, dimethyldichlorsilane)

- Metering of silane with inert gas blanketing (nitrogen) to avoid humidity of air and crystallization

- If required, the system can heat up or cool down the silane in the metering process

- Metering with diaphragm pump technology (hermetically tight and resistant to abrasion)

- Safety valve protects the system from overpressure and damage

- Pressure gauge for the surveillance of pipes on suction and pressure side

- Mass flow meter

- Integrated diagnostic function indicates deviations and disturbances

- High system availability; even wear of pump is recognized to enable timely maintenance

- Exact metering through continuous monitoring: LEWA smart control conducts plausibility tests between the signal of the mass flow meter (actual value) and guide signal (setpoint value). Thus, the silane flowrate is adjusted to the speed of the extruder or the plastic melt mass

- LEWA smart control makes it possible to choose between centralized (multiple extruders controlled by one operating terminal) or decentralized (multiple separate smart control units) operation

Areas of application

Silanes are used in the following industries and products:

- Production of chemical intermediates or chemicals for laboratories

- Adhesion promoters for varnish and paint: for high solid paint with few solvents as well as solvent free powder coating and water-based paint, environmentally friendly paints produced by emulsion polymerization with non-toxic organosilanes (silane-modified acrylate coating)

- Grafting and crosslinking additives for polyethylene in the production of PEX-pipes und XLPE-cables

- Flame retardant compounds that require crosslinked insulation and coating

Background

What is important when metering silane?

In order to meet the production requirements (reproducibility, consistency, product purity etc.) of plastic cables and plastic pipe compounds for the manufacture of cable and/or wire insulation, metering must be precise, easily adjustable, and unaffected by external influences.

The extremely precise metering is effected via a hopper into the extruder (almost pressureless in laboratory applications) or into the process zone of the extruder by an injection pipe which places silane in the melt polymer. The choice of silane type depends on polymers. Special type organosilanes open new possible applications because they are important components of paints and coatings and their adhesion to various grounds is guaranteed for years.

The speed of silane crosslinking in polyethylene of cables can be influenced by:

- Silane type

- Size of the component that has to be crosslinked

- Temperature

- Pressure

- Amount of existing water molecules

- Efficiency of grafting

- Amount of catalyst

Source: Wacker Chemie AG, EVONIK Industries

Industries

Pumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsProducts

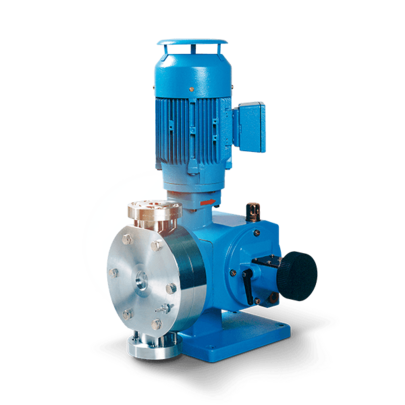

LEWA ecosmart®: Diaphragm Metering Pumps

Experience the innovative LEWA ecosmart, a compact diaphragm metering pump offering multiplex capabilities at a competitive price. We assure the renowned LEWA quality, backed by our 70 years of market expertise. Choose LEWA ecosmart for smart metering pump solutions without compromising on quality or performance.

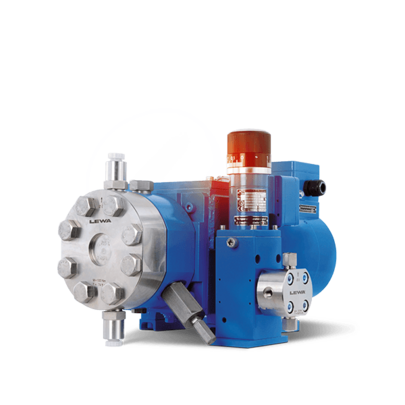

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

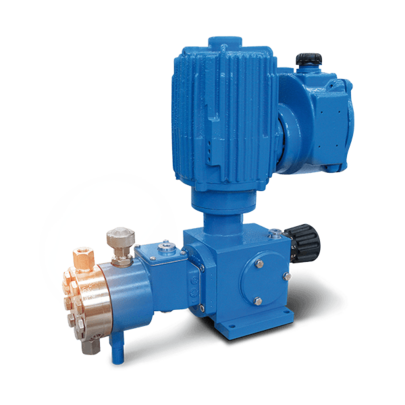

More DetailsLEWA MAH, MBH, MLM Series: Micro-Metering Pumps

Discover our metering pumps designed for ultra-low flow rates, offering an exceptionally cost-effective solution for proportional metering of fluid components to variable reference values. Ideal for precision applications.

More DetailsLEWA FC: High-Precision Laboratory Metering Pumps

Explore our precision metering pumps designed for micro-flow rates. The FC series, capable of handling pressures up to 400 bar, is tailor-made for laboratory and test center applications, offering unparalleled accuracy for small-scale fluid management.

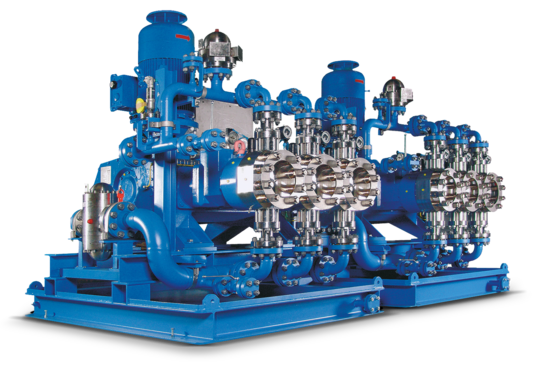

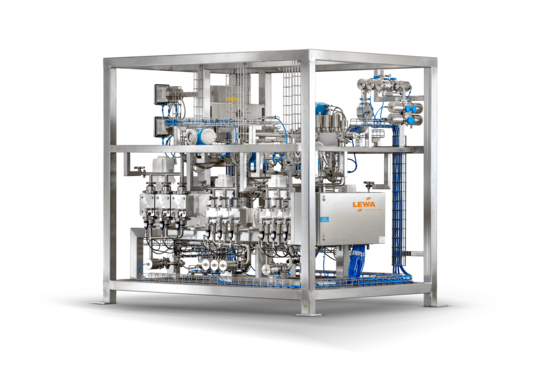

More DetailsLEWA Pump Skids

Ready-to-operate, custom-designed pump units with a small-footprint design. We choose all the pumps, materials, and accessories for these pump skids.

More DetailsLEWA ecofoam® Blowing Agent Metering System

Redundantly designed, absolutely leak-proof system working in combination with extruders for metering various blowing agents in plastic production.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details