Solution

For metering filter aids during filtration, the LEWA ecodos sanitary/hygienic design is an optimum solution, because it is designed for handling diatomite suspensions.

- LEWA ecodos sanitary/hygienic without a stuffing box has a surface quality of 0.5 µm and is suitable for continuous operation

- Valves are of the SA design with valve seat inserts made of VA 80 and equipped with dairy pipe connections

- Hermetic seal of the pump prevents contamination of the product

- Patented 4-fold safety diaphragm made of PTFE, diaphragm and seal are FDA-compliant

- During the filtration process, the pump continuously pushes the liquid with the diatomite suspension through, so that the filter cake remains porous at the filter plates

- Extremely small dead space makes it easy to clean the entire pump and provides for sterility of the product

- Cleanable with CIP/SIP

Background

How are filter aids metered in the beverage industry?

Before the bottling, beverages like beer, wine or fruit juices have to be filtered, which means, undesired solids have to be separated from the fluid. For successful filtration, a filter aid is needed. An example for such a filter aid is kieselguhr, which filters out yeast and protein components of high molecular weight. The filtration process begins with a precoating of the filter plates.

A consistently distributed kieselguhr suspension is metered into a water flow or directly into the product. From then, kieselguhr has to be added constantly, so that the filter cake remains porous. Because of the added filter aid, the filter cake grows continuously and increases the filter depth. If enough kieselguhr is dosed, the lifetime of the filter can be optimized.

Industries

Pumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsProducts

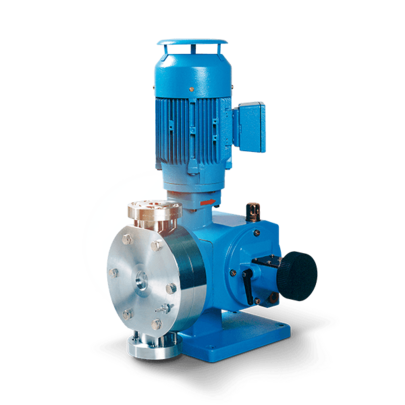

LEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

More DetailsLEWA ecodos®: Sanitary / Hygienic Diaphragm Metering Pumps

The LEWA ecodos is also offered in a sanitary/hygienic version, expertly meeting all operational standards for pharmaceutical and food production metering pumps.

More Details