Solutions

Solutions for the extraction of nickel

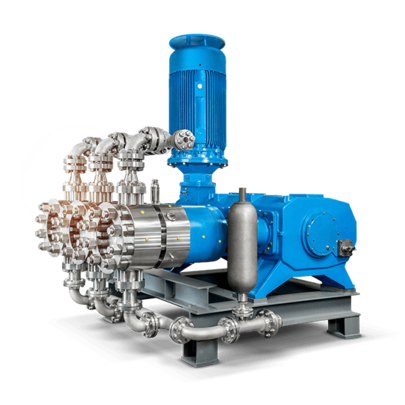

LEWA triplex process diaphragm pumps possess optimum properties for metering sulfuric acid in nickel production: they are robust and durable. Thanks to their hermetic tightness, they enable corrosive sulfuric acid to be metered safely.

Advantages of LEWA triplex pumps for nickel mining at a glance:

- Designed for continuous operation: One-piece drive housing with vertically flanged motor and dual -bearing crankshaft.

- Monoblock design: Required components such as bearings and seals are reduced to an absolute minimum, resulting in an extremely compact, space-saving design.

- The flow rate can be controlled by a frequency converter which regulates the number of strokes per minute and thus the flow rate.

- The pump heads with hydraulically actuated sandwich diaphragms made of pure PTFE are designed for discharge pressures up to 350 bar or flow rates up to 19 m³/h. They are protected against incorrect operation and against impermissible operating conditions.

- An integrated, individually adjustable pressure relief valve in the hydraulic section prevents possible overload situations during operation.

- The patented DPS protection system and the diaphragm monitoring system report any damage before leakage can occur. The risk of sulfuric acid leakage is thus minimized.

- Maintenance is very low because the metered sulfuric acid does not come into contact with rotating components: all moving parts operate in a protective and lubricating hydraulic fluid.

- Special cone valves with valve seats and plugs made of Hastelloy for trouble-free continuous operation.

- The pumps are smooth running and have a low pulsation flow. Therefore, pulsation dampeners are often not needed.

This makes them ideally suited for use in the HPAL process.

Background

The high pressure acid leaching (HPAL) process is used to process the nickel ore.

In HPAL, nickel laterite reacts with sulfuric acid in the autoclaves and nickel in the form of sulfate is leached at both a high temperature and high pressure, while iron in the form of hematite enters the leached residue. By washing and thickening, the leached solution is precipitated to produce an intermediate product of nickel-cobalt sulfide or nickel-cobalt hydroxides. This product can then be leached, extracted and electrolytically recovered to produce stainless steels or be used in battery production.

Industries

Soluciones de bombeo para minería y procesamiento de metales y minerales.

Desde la fabricación de explosivos, la extracción de minerales y la recuperación de metales y minerales hasta el tratamiento de efluentes y el acabado del producto final, nuestras soluciones han ayudado a nuestros clientes a ahorrar energía y consumibles al tiempo que mantienen una alta seguridad operativa y un bajo costo de propiedad.

More DetailsProducts

Bombas de proceso LEWA triplex® para proceso de alta presión

La bomba de membrana de proceso LEWA triplex® cuenta entre las bombas de alta presión más compactas del mundo y puede incluso montarse en los lugares más angostos, cuando el ahorro de espacio es vital. Este pack de potencia ha demostrado sus cualidades en numerosos procesos de alta presión y en distintos sectores. Icono de petróleo y gas Icono de olor a gas gris Icono de refinería Icono de petroquímicos Icono de químicos Icono de plásticos icono gris Icono de limpieza Icono de cosméticos Icono de farmacéutico Icono de alimentos Icono de energía Otro icono

More Details