Geveke Nitrogen Generation Packages.

Onsite nitrogen generation for oil and gas applications.

In the oil and gas industry and in refineries there is a wide range of applications where pure nitrogen is used. The gas to minimizes dangers of fire and explosion risk as well as unwanted oxidation. Spots of use are piping systems, tank ventilation, dry gas seals or tank blanketing.

In many cases, the nitrogen is recovered from nitrogen bottles. This, however, means dependencies from external suppliers. If large amounts of nitrogen are required or the production plant is in a remote location (or offshore), the regular replenishment of the nitrogen bottle is not only difficult, but also expensive and time consuming. Geveke Nitrogen Generation Packages produce high purity nitrogen directly from the air, so that an independent supply is ensured locally.

Good reasons for Geveke Nitrogen Generation Packages

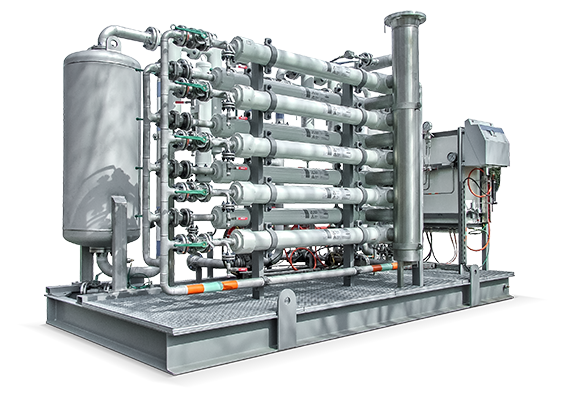

Geveke Nitrogen Generation Packages are optimized for the respective application and are constructed from the highest quality materials.

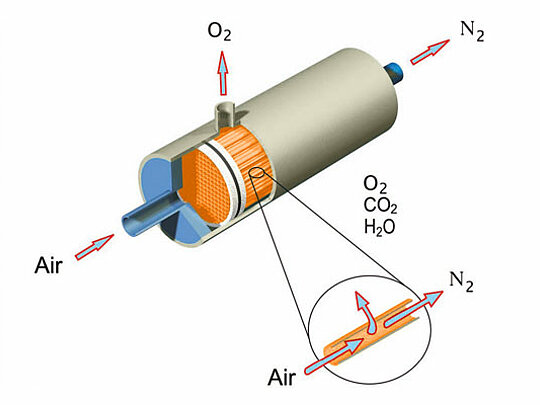

Nitrogen purity to 99.5 % thanks to advanced membrane technology

The SmartFluxx membrane technology is based on the use of hollow fibers with a permeable structure. Thousands of these delicate plastic fibers are packed together in a tube of stainless steel (316) or coated aluminum. During gas-separation, the air is compressed and forced through the tube. Here, the nitrogen molecules remain adhered to the hollow fibers while other substances are filtered out. Geveke Nitrogen Generation Packages produce nitrogen with a purity of 95% -99.5%. This technology does not require additional heating modules and thus provides not only the most efficient but also the most cost-effective solution for producing nitrogen.

Individual equipment sizing

The packages are suitable in the safe area and the Ex-zones. Main factors for the construction is the required nitrogen purity, capacity, available input air pressure and the intake air flow. The basic components are the filter section, the diaphragm portion and the control portion. Variable elements are compressors, filters, instrumentation, automatic valves, controls, buffer tank, gas booster for filling the cylinder and nitrogen bottle racks.

Highest safety through touch control panel

The local control panel includes a programmable logic controller (PLC) with touchscreen. All functions of the Nitrogen Generation Package are controlled and monitored by the panel. Thus the nitrogen generator can also be operated as a stand-alone unit. The unit is fully automatic. Local start and stop functions are included.

Oxygen Analyzer

To ensure the quality of the nitrogen, all Nitrogen Generation Packages are equipped with an oxygen analyzer. The analyzer measures the residual proportion of oxygen in the air generated and thus determines the quality of the nitrogen produced. If the produced nitrogen does not reach the required purity, the off-spec mix can be routed to the outside or the package will be shut down immediately.

Flow Control Valve

Behind the nitrogen membranes there is a flow control valve to adjust the nitrogen purity. The pressure in the nitrogen-membranes can be adjusted by throttling the gas flow.

Pure, high quality compressed air through activated carbon filters

The activated carbon filter is an essential element of Nitrogen Generation Package. It absorbs oil moisture and ozone in order to prevent contamination of the nitrogen and the membranes. All oil aerosols, vapors, odorant and flavoring substances are removed by the active surface of highly porous carbon.

Dust filter with high filter fineness

The filter cartridges determine the fineness of the respective filter. In Nitrogen Generation Packages quality filter cartridges having a fineness of 0.01 microns are in use.

Testing, commissioning and inspections

All components are individually tested and certified. A final functional test of the complete package is carried out before starting up, in which the nitrogen generator must have a completely error-free operation. Inspections are part of the regular maintenance schedule.

Space-saving, simple design

Nitrogen Generation Packages are compact and designed simply. The membrane modules are very compact and thus particularly well suited for applications offshore.

Videos for Geveke Nitrogen Generation Package

LEWA oil & gas

LEWA offers pumps and systems for different applications in the oil and gas industry, regardless whether offshore, onshore or in refineries. In this video, we show typical products for the oil and gas market with numerous products working in various extreme climatic conditions.

LEWA oil & gas

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA - The 40 Million Dollar Job

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

Industries

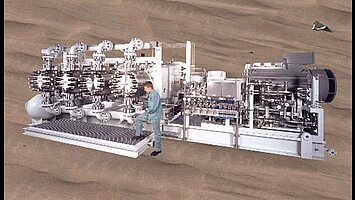

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsPumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More Details