In 2018 alone, the shipping industry caused a total of 1,076 million tons of greenhouse gas emissions, including 1,056 million tons of CO2. Compared to 2008, this represents an increase of around 90 percent. If the industry does not change, levels are expected to rise to up to 130 percent of those from 2008 over the next 25 years. To improve these forecasts, the International Maritime Organization (IMO) developed a greenhouse gas strategy in 2018 that aims to reduce the shipping industry's carbon dioxide emissions by 40 percent by 2030 and by a total of 70 percent by 2050. In addition to the ECAs defined in the MARPOL agreement, which are to be further expanded in the future, the Energy Efficiency Design Index for New Ships (EEDI) and the Ship Energy Efficiency Management Plan (SEEMP) regulate the energy efficiency and CO2 emissions of newly built ships. Older models with more than 400 GT, on the other hand, have had to comply with the new regulations of the Energy Efficiency Design Index for Existing Ships (EEXI) since 2023.

Liquid ammonia as a sustainable marine fuel

With the aim of reducing emissions and fuel consumption while increasing performance and ensuring cost-efficient operation, dual-fuel variants of two-stroke marine diesel engines have been conquering the market for several years now. They enable a high degree of flexibility with regard to the fuels used, from pure marine diesel or heavy fuel oil operation to gas operation. On the gas side, LNG and LPG (propane/butane), which are particularly suitable for liquefied gas tankers, have mainly been used to date. However, these are fossil gases, and while they release fewer pollutants overall during combustion, they still release a considerable amount of CO2. LNG also consists predominantly of methane (CH4), which is around 25 times more harmful to the climate than CO2 and, in two-stroke marine diesel engines, small amounts inevitably escape – a phenomenon called methane slip. For this reason, LNG and LPG are merely bridging technologies on the way to completely carbon-free ship propulsion.

First used as an alternative fuel in 1943 due to a diesel shortage, ammonia (NH3) does not emit particulate matter, nitrogen oxides or CO2 during combustion and has no ozone depletion potential. Until now, it has been obtained from nitrogen (N2) and hydrogen (H2) using the Haber-Bosch process, which requires a great deal of energy. The production of hydrogen is particularly critical from an environmental point of view, as H2 has so far been split off from fossil methane gas. However, with the development of processes for the sustainable production of H2 via electrlysis using renewable energies on an industrial scale, NH3 is now becoming an attractive fuel for clean and sustainable ship propulsion systems. This also provides a positive answer to the important well-to-wake (WTW) question: When considering new fuels, it is crucial to take into account not only the combustion process in the ship's engine, but also the entire balance of fuel production. Thanks to the new processes, NH3 can also be an attractive option.

At the end of 2023, the world's first ammonia project for bulk carriers was launched. In a four-party agreement, the Belgian bulk carrier operator CMB.TECH appointed the engine manufacturer WinGD as well as CSSC Qingdao Beihai Shipbuilding (QBS) and CSSC Engine Co (CSE) to produce the first eight 210,000 DWT bulk carriers powered by NH3. These are to be delivered over the next three years.

Hermetically tight pump technology in NH3 dual-fuel drives

Engine manufacturer MAN Energy Solutions also anticipates a rapid increase in the fuel to around 40 percent of the total fuel mix for dual-fuel two-stroke engines by 2030. Given these promising forecasts, it is hardly surprising that the order for the first ammonia cargo ships has already been placed, even though the marine engines for this application are still under development. Compared to LPG or LNG, NH3 poses its own challenges as a fuel: Even in very small quantities, the odorous gas is highly toxic to humans and animals, and it reacts with other air pollutants to form unwanted particulate matter in the atmosphere.

Fail-safe, hermetically tight pump technology is therefore required to move NH3 safely and reliably within the ship and inject it precisely into the engine. The challenge: Conventional plunger pumps, which are usually used for these kinds of high-pressure applications, have a natural leakage at the plunger seal due to their design. For the fuel gas supply systems (FGSS) in dual-fuel ship propulsion systems with NH3, only high-pressure diaphragm pumps designed without dynamic seals can therefore be considered. This creates a hermetically tight working chamber that rules out the possibility of emissions.

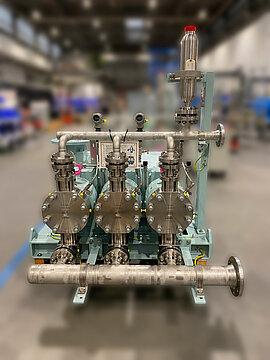

LEWA triplex diaphragm pumps for FGSS

Thanks to their robust design with maximum operational reliability, the low-pulsation LEWA triplex diaphragm pumps have so far proven themselves as fuel pumps in FGSS, primarily for LPG – but nothing stands in the way of their use with NH3. The required pressures of approx. 85 bar can be realized very easily with LEWA triplex diaphragm pumps. For the pump heads of the M900 series, which have been proven in the field for many years, this value is even in the lower range of the possible performance spectrum, which extends up to 500 bar. Particles or oil residues in the fuel can also be conveyed without any problems. As the diaphragm pumps are dry-run safe to an unlimited degree, costly failures cannot occur even if other faults occur in the FGSS. In addition, the systems are designed in such a way that they can be maintained and repaired by the crew directly on board using simple means.

The patented sandwich diaphragm with integrated monitoring system ensures that the LEWA triplex diaphragm pumps remain hermetically tight even if the diaphragm is damaged. This guarantees that no dangerous NH3 can escape, even under extreme operating conditions. Integrated overpressure protection and optional pump monitoring by LEWA Smart Monitoring supplement the high standards of operational safety. Intelligent monitoring systems will generally become more relevant in the shipping industry over the next few years, as digitalization is also being advanced in this field. Often, newly built freighters are already being made "smarter". As NH3 is a clean and sustainable marine fuel in the long term, corresponding drives could also play a role in the development of autonomous smart ships in the coming decades.

More Information: www.lewa.com/en/applications/process-diaphragm-pumps-as-high-pressure-fuel-injection-pumps-for-marine-engines