Solution

Advantages of LEWA diaphragm pumps for glycol injection:

- Leak-free, hermetically sealed

- Very easy diaphragm replacement

- All movable parts operate in protective, lubricating hydraulic fluid

- Very long service life (often more than 10,000 hours of continuous operation)

- Convincing "Total Costs of Ownership" (TCO): LEWA offers the necessary equipment with the lowest downtimes, low maintenance, low friction losses and low energy consumption and most efficient pumps

Background

Process description

Gas dehydration using glycol

The glycol is separated from the gas and containes moisture with it. The absorbed moisture also contains contaminants, such as H2S, sulfur and solids, that make the water acidic and extremely corrosive.

The low pH value is neutralized by the injection of caustic soda. Afterwards the glycol is heated to about 120° C, vaporizing the water content. The glycol is then ready for recycling and can be injected back into the incoming gas.

In addition to the glycol injection, every large drying system always requires one or more chemical injection systems for neutralization.

There are various processes – from simple injection to so-called high speed columns (GESIP® process) – which ensure fast drying and allow a high gas flow.

Industries

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsProducts

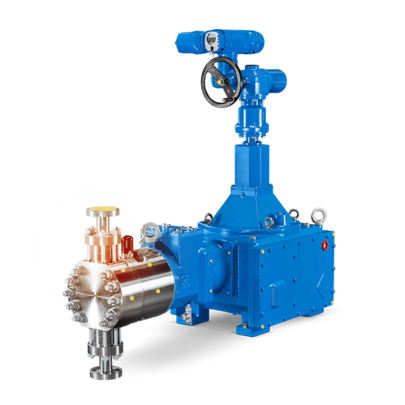

LEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

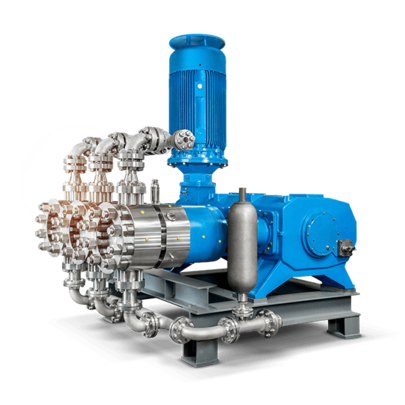

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

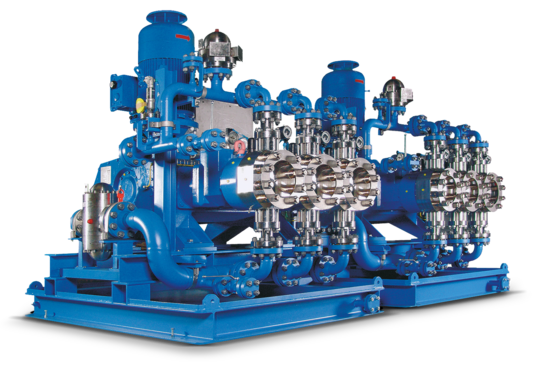

More DetailsLEWA Chemical Injection Packages

Developed and manufactured by the leading pump manufacturer. Customer-specific packages for chemical injection in the oil and gas industry.

More DetailsLEWA Pump Skids

Ready-to-operate, custom-designed pump units with a small-footprint design. We choose all the pumps, materials, and accessories for these pump skids.

More Details