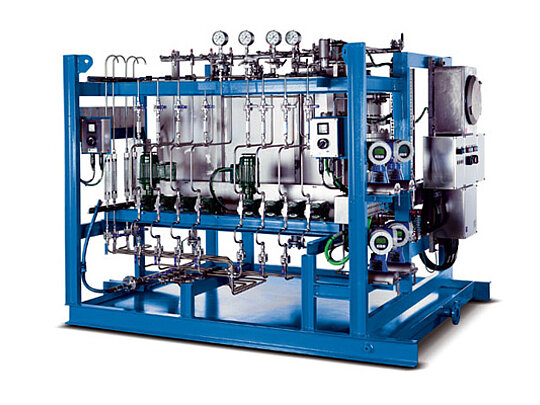

LEWA Chemical Injection Packages

The ideal injection system for every application.

Injection systems for chemicals are subject to stringent requirements, with custom designs usually needed for the application in question. There is also enormous demand for reliability and easy maintenance on off-shore platforms and in extremely hot or cold environments.

LEWA thrives on challenges just like these: Thanks to our expertise, we are able to offer Chemical Injection Packages that are not only custom-made, but also feature unsurpassed reliability and quality. We develop skids and packages that comply with both your specifications and international standards (such as ASME, API, and ATEX), and coordinate processing with our global project management team and production facilities.

From the initial sketch through to the finished system – with LEWA, you get everything from a single source.

Good reasons to choose a LEWA Chemical Injection Package

A LEWA Chemical Injection Package is a complete system that includes an optimized pump design featuring a tank, accessories, and instrumentation

Complete development from a single source

LEWA operates its own in-house development department for hydraulics, mechanics, electrical engineering, and instrumentation. These individual specialisms are perfectly synchronized to develop and implement your custom solution. This means that we can guarantee efficient order processing while complying with the most stringent of quality standards.

Over 60 years of industry experience

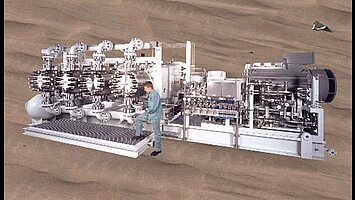

From the Arctic Circle to the Arabian desert: Virtually every oil and gas producer throughout the world puts its trust in LEWA systems. The enormous wealth of experience we have accumulated over more than 60 years in business allows us to provide expert advice and work with you to develop and implement the perfect solution for your needs.

Production sites all over the world

LEWA has a global network of branch offices and production centers. This allows us to ensure that your project will be implemented quickly and economically. Your local contacts are always close by and ready to offer you expert advice on any question.

Outstanding service around the clock

There for you when you need us: Our global commissioning and consultancy services are available 24/7. You'll have constant access to a qualified contact person who will take the time to give you expert advice on anything you need to know about.

Videos about Chemical Injection Packages

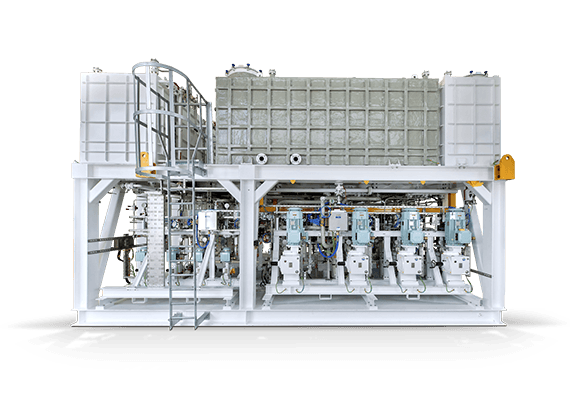

The biggest Chemical Injection Package ever built by LEWA

Over 40 diaphragm pumps, 120 chemical injection points, over 3,000 valves and instruments, 18 chemical storage tanks – LEWA’s biggest Chemical Injection Package ever is a sophisticated record project realized by the highly skilled LEWA engineers. The German manufacturer of world-class pumps invested 7,500 engineering hours to realize the 715 ton weighing package. The Chemical Injection Package with its enormous dimensions of 21 x 21 x 11 meters was a showcase project in terms of engineering as well as project management and organization.

The biggest Chemical Injection Package ever built by LEWA

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA - The 40 Million Dollar Job

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

LEWA oil & gas

This content is provided by YouTube. If you activate the content, personal data may be processed and cookies set.

Options

Different drive types

We flexibly react to environmental conditions: Pumps in our Chemical Injection Packages are driven by electric (solar energy), compressed air, gas or diesel engines.

Flexible construction of storage tanks

The storage tanks are constructed in rectangular or cylindrical design. If necessary, we use a multi-chamber system, depending on your requirements.

Pressure-dependent piping

At higher pressures, we recommend obtuse or socket welded pipes. Up to a pressure of 20,000 psi, we use tubing for the supply and the outflow of liquids if required.

High-alloy construction materials

In the construction of a Chemical Injection Packages, we use high alloy materials such as Incoloy, monel, titanium, and Hastelloy. Other options are available on request.

Calculation of fluid dynamics

When designing pumps and systems, we rely on computer-based calculations of the fluid dynamics in the pipelines and on appropriate integration of pulsation dampers.

Assembly on site

From engineering to commissioning – all from a single source: Our systems are suitable for sea transport and can be completely disassembled and reassembled at the destination.

Testing, acceptance and inspection

We make sure that everything works: LEWA offers numerous services, including factory acceptance test (FAT) at the manufacturing site or at your site (SAT), NDT and PMI.

Global commissioning

With our global service network, we take your equipment into operation and provide technical service directly at your location - both onshore and offshore.

High reliability

No matter if offshore in rough seas or onshore in the hot Arabian desert: Our systems are characterized by exceptional reliability and availability even under extreme conditions.

Technical data

Our Chemical Injection Packages are designed for a range of applications. Thanks to the modular assembly concept that can incorporate different types of pumps, we are able to guarantee maximum flexibility.

Adjustable flow rates and discharge pressures

Our packages are suitable for flow rates from 5 ml/h to 180 m3/h. With diaphragm pumps, the system is able to operate pressure levels of up to 1200 bar. Plunger pumps, meanwhile, enable discharge pressure levels of as much as 3500 bar to be achieved. The injection system can store a maximum volume of 50 m3.

Pumps used compliant with API standards

The metering pumps used in our Chemical Injection Packages are all API 675-compliant and our plunger pumps all meet API 674 standards. Each of the two pump types is available in a single-pump head or multiple-pump head configuration. This means we can guarantee maximum flexibility when designing your Chemical Injection Package.

Industries

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsPumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsApplications

Injection of corrosion inhibitor

Do you require systems for the injection of corrosion inhibitor? At LEWA, you can find expert consultation, detailed information and support!

More DetailsMethanol injection

Use skids and packages by LEWA for methanol injection in the oil and gas industry. Ask our experts for more information!

More DetailsGas drying with glycol

LEWA provides reliable injection pumps and systems for gas drying with glycol. Ask our experts for more information today.

More DetailsInjection of demulsifiers

Injection of demulsifiers with LEWA packages in the oil and gas industry. We provide you with advice tailored to your application.

More DetailsSolar pump for onshore production

For more than 30 years LEWA has been providing autonomous chemical injection systems with solar-powered metering pumps.

More DetailsProcessing of produced water

Produced water packages from LEWA can be used to purify produced water during oil drilling. They are hermetically sealed and have options for exact control.

More DetailsDownloads

LEWA Lösungen für die Öl- & Gasindustrie. (DE)

High-end Dosier- und Prozesspumpen sowie Systeme und Packages für spezifische Funktionalitäten zum Einsatz in der On- und offshore Förderung.

4 MB

| pdf |

18.10.2022

LEWA Solutions for the Oil & Gas Industry. (EN)

High-end metering and process pumps as well as systems and packages for specific functions for use in onshore and offshore production.

4 MB

| pdf |

18.10.2022

Soluciones de LEWA para la industria del petróleo y gas. (ES-SA)

Bombas de dosificación y de proceso de alto nivel, así como sistemas y paquetes para funciones específicas para su uso en producción tanto en la tierra como en el mar.

3 MB

| pdf |

18.02.2022

LEWA Solutions for the Oil & Gas Industry. (USA)

High-end metering and process pumps as well as systems and packages for specific functions for use in onshore and offshore production.

4 MB

| pdf |

06.11.2022