LEWA Switzerland AG

The best choice for metering pumps and systems

We work closely with you to find the best solutions using tried-and-tested cutting-edge technology. The best technology is the basis; proximity to customers and process expertise are the challenge.

We place importance not only on outstanding technology, but also the intelligent design of the entire process. To reach this goal, we don't hesitate to think outside the box and question the traditional way of doing things. Because synergies are important, we also provide you with advice in the name of renowned manufacturers in the range of neighboring products and carry the following products:

- Compressed-air-driven double-diaphragm pumps

- Gear pumps

- Centrifugal pumps

- Rotary lobe pumps

- Magnetic drive pumps

- High-pressure centrifugal pumps

- Piston and diaphragm compressors

Even after delivery, we are there for you and provide comprehensive services and maintenance for your products in Reinach or at your location. Our experienced and trained personnel is available for finding the solution to your problem.

Facts about LEWA Switzerland AG

LEWA Switzerland AG is active in numerous European countries and fulfills all important requirements and certifications for pumps and systems.

| About LEWA Switzerland |

|---|

| Managing Director: Pietro Pettoruto |

| Company founded: 1976 |

| Headquarters: Reinach, Switzerland |

| Certified Modular Workshop for successful workshop quality audit and excellence in service practices |

| Certified in accordance with*: DIN EN ISO 9001 • GOST R • AEO-C |

| Pump design in accordance with*: API 674 • API 675 • 94/9 EC (ATEX) |

| Hygiene certifications*: EHEDG • FDA • QHD |

| Members of*: VDMA • Europump • Hydraulic Institute • ISPE • 3-A • EHEDG |

*Certifications of LEWA GmbH

Industry Expertise

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsGas Odorization with LEWA Pumps and Metering Packages

Natural gas, oxygen, and nitrogen are odorless but potentially dangerous. This is why these gases are "odorized" with as strong a smelling substance as possible. For more than 40 years, LEWA has been developing systems for the odorization of gases such as natural gases, biogases, and liquefied gases. This process is enormously important, so the odorizing system has to operate precisely and reliably.

More DetailsPumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsPumps and Systems for the Manufacture of Detergents and Cleaners

LEWA offers continually operating, formula-controlled systems for the manufacture of household and industrial cleaners in all commercially available surfactant concentrations – from raw product to end product. Contact our experts and let us advise you – we will work with you to configure pumps and systems for the manufacture of detergents and for the production of other cleaners.

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsPumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsMetering Packages and Pumps for Power Plants and Power Suppliers

LEWA supports power plant operators and power suppliers with pumps and systems for conveying, metering, and mixing different fluids. We not only provide power plants with our products, but also develop solutions for wastewater treatment plants, gas bottlers, biogas producers, regional power suppliers, and hydrogen producers.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsPartner product brands

Pomac rotary lobe pump

The flexible and economical positive-displacement pump for hygienic standard applications all the way to complex sterile applications with low-viscosity, viscous and/or shear-sensitive media.

More DetailsPomac PDSP double screw pump

Pomac PDSP double-screw pumps are ideally suited for a variety of processes in the food, beverages, cosmetics and pharmaceutical industries. They are extremely economical because they are suitable for conveying and for sterilizing/cleaning (2 in 1).

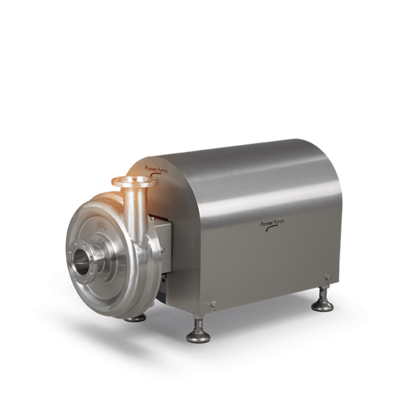

More DetailsPomac centrifugal pump

The stainless-steel Pomac centrifugal pumps for low-viscosity media feature optimum hydraulic data, a unique modular design and numerous options available in the area of shaft seals. It is available in various versions.

More DetailsVersa-Matic air-operated double diaphragm pump

Versa-Matic pumps feature easy handling, reliable operation, high performance, small size and low weight. They are also dry-run safe, self-priming over 7.5 m, submersible and capable of stepless adjustment using compressed air.

More Details