Solutions

Safety, efficiency and economy to harsh applications

The following advantages are offered by the LEWA process pumps for the injection of sulfuric acid in tanks and pipelines:

- Hermetically tight: reduced risks of accidents and waste of chemicals due to leakage

- High efficiency: energy in mines is a limited resource. The LEWA process pumps have a higher efficiency than centrifugal ones, demanding less power to run and smaller motors, cables and panels

- Low maintenance: pumped fluid does not have contact with rotating parts, while all movable parts operate in protective, lubricating hydraulic fluid

- Easy control: pumped volume is known and proportional to motor speed, making it easy to control the concentration of the solution

- Lowest downtime: often more than 10,000 hours of continuous operation

- Flexibility: landscape of mine sites changes all time, so does the pump installation. Our pumps keep the desired flow rate regardless the new counterpressure of the installation

Background

Copper oxide heap leaching

Copper oxide ores are processed using aqueous solutions to extract and purify copper in three steps:

Heap leaching is the use of percolating chemical solutions to leach out metals. Following mining, transporting and crushing to a consistent gravel-size, the ore is piled into a heap on top of an impenetrable layer on a slight slope. The leaching reagent (dilute sulfuric acid) is sprayed through sprinklers on top of the heap pile and allowed to trickle down through the heap, where it dissolves the copper from the ore. The resulting solution of sulfuric acid and copper sulfate is collected in a small pool. Copper concentration is around 65%.

Next step is solvent extraction. The leach solution is mixed vigorously with a solvent. The copper migrates from the leach solution into the solvent. The two liquids are then allowed to separate based on solubility, with copper remaining in solution in the solvent, and impurities remaining in the leach solution.

The leftover leach solution is then recycled by adding additional acid – the LEWA pump application – and sent back to the sprinklers in the heap leaching process.

The last step is electro winning. An electrical current passes through an inert anode (positive electrode) and through the copper solution from the previous step, which acts as an electrolyte. Positively-charged copper ions (called cations) come out of solution and are plated onto a cathode (negative electrode) as 99.99% pure copper.

Industries

Pumping solutions for mining and metal and mineral processing

From the explosives manufacturing, ore extraction and metal and mineral recovery to effluents treatment and final product finishing, our solutions have helped our clients to save energy and consumables while keeping high operational safety and low cost of ownership.

More DetailsProducts

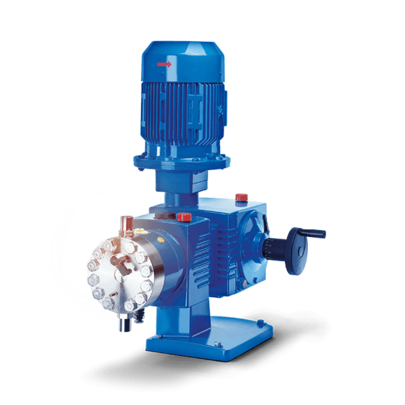

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecoflow® Packed Plunger Metering Pumps

Opt for the LEWA ecoflow packed plunger metering pump, a robust and reliable choice for hassle-free fluid metering. Available in multiple models to suit diverse processes, it's the metering pump trusted by industry leaders for consistent performance.

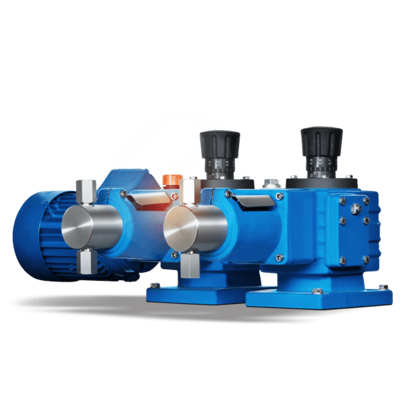

More DetailsLEWA ecosmart®: Diaphragm Metering Pumps

Experience the innovative LEWA ecosmart, a compact diaphragm metering pump offering multiplex capabilities at a competitive price. We assure the renowned LEWA quality, backed by our 70 years of market expertise. Choose LEWA ecosmart for smart metering pump solutions without compromising on quality or performance.

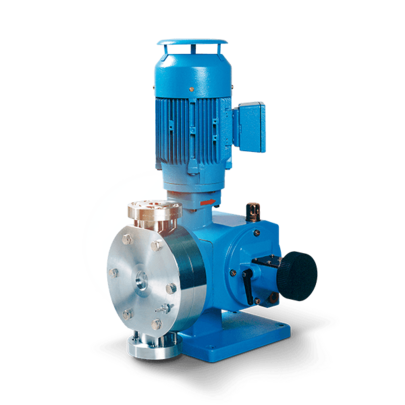

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

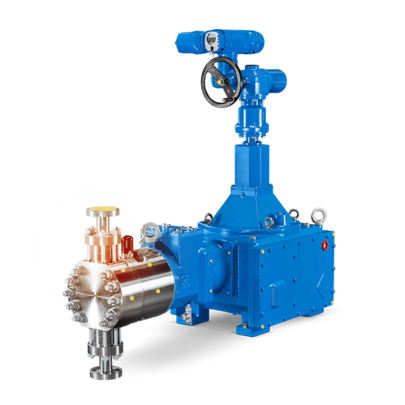

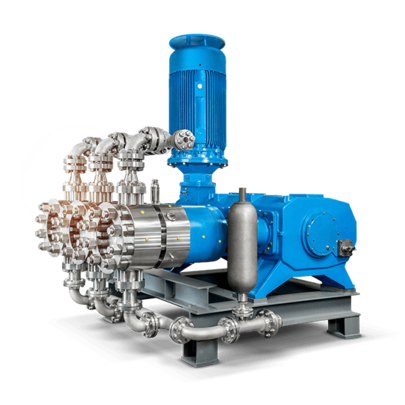

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

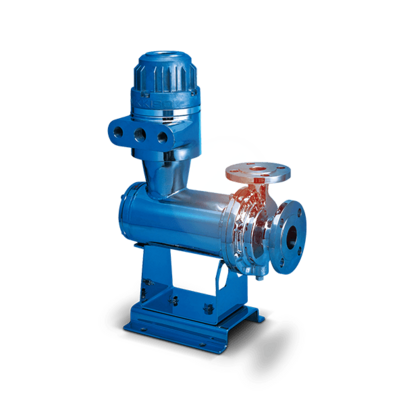

More DetailsNIKKISO NON-SEAL canned motor pump

The NIKKISO NON-SEAL canned motor pump has been designed specifically for the chemical industry. To do this, the centrifugal pump is designed in accordance with API 685.

More DetailsVersa-Matic air-operated double diaphragm pump

Versa-Matic pumps feature easy handling, reliable operation, high performance, small size and low weight. They are also dry-run safe, self-priming over 7.5 m, submersible and capable of stepless adjustment using compressed air.

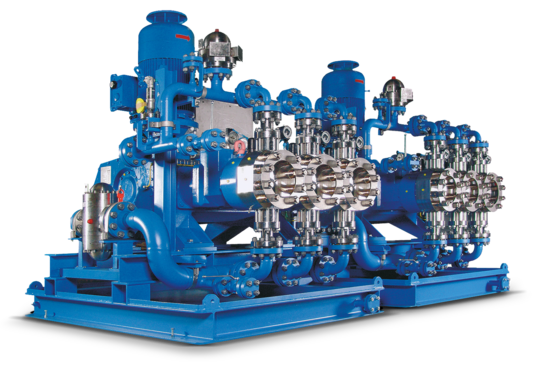

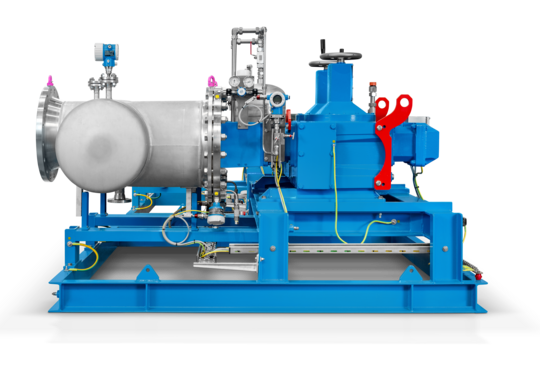

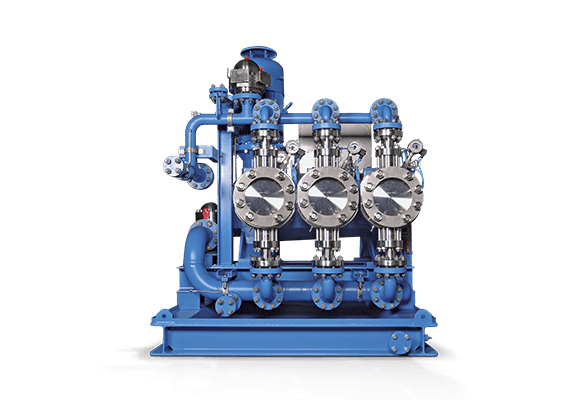

More DetailsLEWA Pump Skids

Ready-to-operate, custom-designed pump units with a small-footprint design. We choose all the pumps, materials, and accessories for these pump skids.

More DetailsLEWA Bellows Pulsators

The perfect solution for generating oscillating fluid flows in vertical vessels for a quicker chemical reaction.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details