Solution

For the production of gelatine products, LEWA provides a series of solutions for various process steps:

- By using multiplex pumps for recipe metering or complete systems, LEWA provides hygienic alternatives in the entire process for producing gelatine.

- For each component of the recipe metering (sugar and gelatine solution, color, flavor, acid, etc.) a metering unit is used that consists of at least one LEWA metering pump and a downstream static mixer.

- As early as the project stage, calculations are carried out for optimizing the suction side conditions.

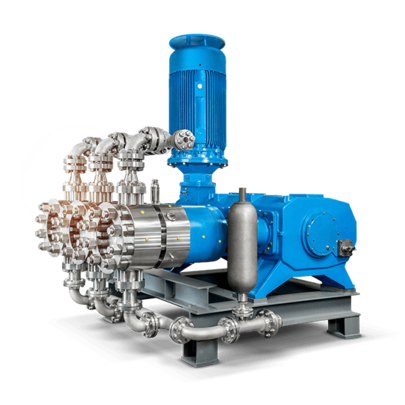

- LEWA multiplex process pumps with a hygiene-compliant diaphragm pump head are the tried-and-tested solution for sterile metering of gelatine into a cooler.

- LEWA multiplex pumps always convey with the greatest precision, even at a counterpressure from 20 to 50 bar, which can arise during the drying process.

- Sanitary/hygiene-compliant design of the pumps used with the least dead space

- Wetted parts are FDA-compliant as well as tested and documented for USP Class VI

- Material certificates in accordance with EN 10204 3.1

- Surfaces of the pump polished mechanically (316/316L-1.4401/1.4404: RA < 0.8µm) or polished mechanically and electro-polished (1.4435: RA < 0.5µm).

- Easy to clean in accordance with recognized industrial standards (EHEDG, QHD, FDA and USP Class VI-compliant)

- The pumps can be sterilized with hot water or steam at up to 150 °C.

Background

How is gelatine produced?

There is a distinction made between bone gelatin, which is obtained from long bones of the legs of calves and cattles and dermic gelatin, which is derived from tanneries waste, pork rind and cows’ and cattles’ heads.

The bones are cleaned, shredded and macerated. The tricalcium phosphate in the bone tissue is removed with dilute hydrochloric acid. Then, it is multiply watered and treated with lime water (“liming”). The next steps are the neutralization of the acid and further washing procedures.

The gelatin is extracted from the washed-out bone collagen in multiple steps, pre-cleaned in separators and afterwards filtrated.

The filtration is a typical application for metering pumps: Diatomaceous earth or perlite slurries are added to the alluvial filter. Flow rates are below 360 l/h and pressures are below 8 bar.

The separation yields an aqueous gelatin solution with a concentration of approximately 6 %. The gelatin content is increased to approx. 30 % in a single or multi-stage vacuum evaporation column. The viscosity goes up to 1500 mPa∙s. This solution now is fed to a drying process.

This is the main application area for multiplex pumps. The task of these pumps is the germ-free metering of the gelatin into a cooler with subsequent fragmentation and drying. The transition from gel-type state to solid state leads to back pressures from 20 to 50 bar.

Industries

Pumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsPumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsProducts

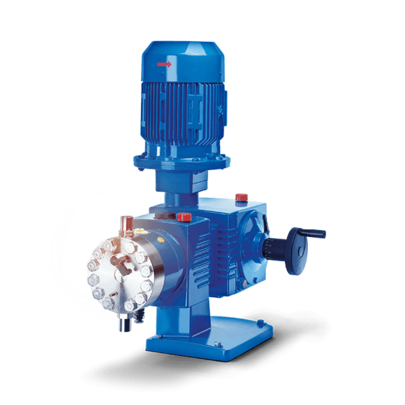

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecoflow®: Hygienic Diaphragm Metering Pumps

Discover the LEWA ecoflow® in its hygienic version, designed for sanitary applications. This versatile metering pump maintains its renowned all-around performance while meeting the stringent hygienic standards required in pharmaceutical and food production industries.

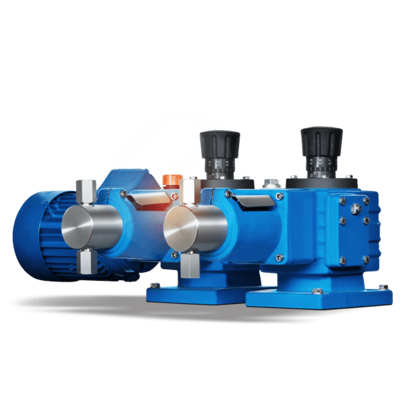

More DetailsLEWA ecoflow® Packed Plunger Metering Pumps

Opt for the LEWA ecoflow packed plunger metering pump, a robust and reliable choice for hassle-free fluid metering. Available in multiple models to suit diverse processes, it's the metering pump trusted by industry leaders for consistent performance.

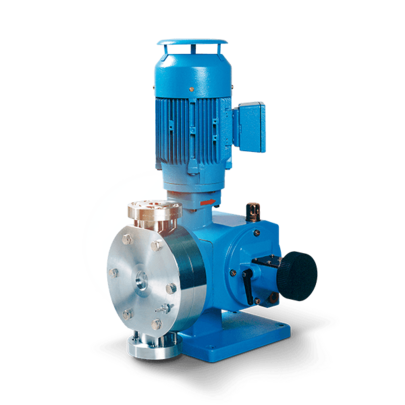

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

More DetailsLEWA ecodos®: Sanitary / Hygienic Diaphragm Metering Pumps

The LEWA ecodos is also offered in a sanitary/hygienic version, expertly meeting all operational standards for pharmaceutical and food production metering pumps.

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More DetailsPomac rotary lobe pump

The flexible and economical positive-displacement pump for hygienic standard applications all the way to complex sterile applications with low-viscosity, viscous and/or shear-sensitive media.

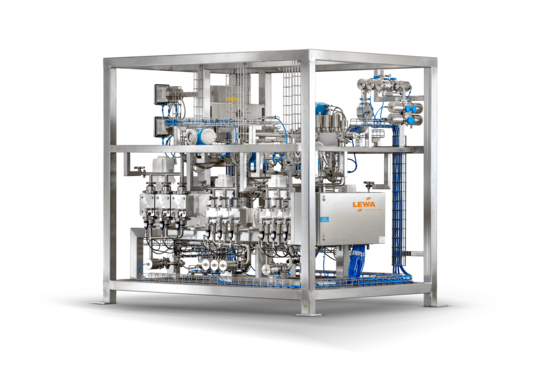

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details