Solution

Remote-head metering pumps are used for coal injection because they offer the following benefits:

- Reliable operation thanks to spatial separation of the valve head and displacement system

- A falling hydraulic connecting line (if necessary, with cooling jacket) prevents sedimentation in the fluid chamber.

- A flushing pump keeps slurry particles away from the plunger seal.

- The hermetic seal of our pump technology ensures reliable conveyance of potentially hazardous substances, which are required for the chemical reaction (e.g. hydrocyanic acid or hydrogen sulfide).

- Any gas bubbles that have accumulated are carried away through the gas removal valve and into the main line by a small discharge flow.

Background

How and why is coal refined?

Coal refinement enables the production of various successor products from coal. Raw lignite cannot be used until it has been processed in a coal refinery, for example, by being made into briquettes, pulverized lignite or fluidized-bed lignite.

One kind of coal refinement is coal liquefaction, which uses the Fischer-Tropsch method, among others. For this, the coal must first be gasified at temperatures over 1000 °C while steam and air or oxygen are fed. The resulting synthetic gas is then cooled. During this process, phenol, liquid ammonia, carbon dioxide, hydrogen sulfide, hydrocyanic acid and organic components are removed from the gas. Then the synthetic gas is converted into hydrocarbons (such as paraffins and alcohols) in a heterogeneous catalytic reaction.

A Fischer-Tropsch synthesis results in various end products such as synthetic gasoline, diesel, heating oil and diverse raw materials for the chemical industry.

Industries

Pumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumping solutions for mining and metal and mineral processing

From the explosives manufacturing, ore extraction and metal and mineral recovery to effluents treatment and final product finishing, our solutions have helped our clients to save energy and consumables while keeping high operational safety and low cost of ownership.

More DetailsProducts

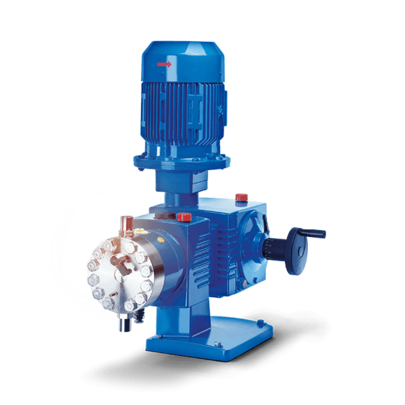

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

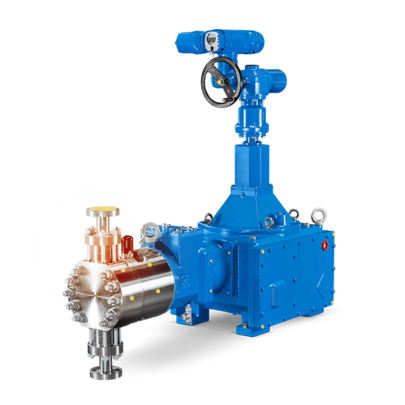

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

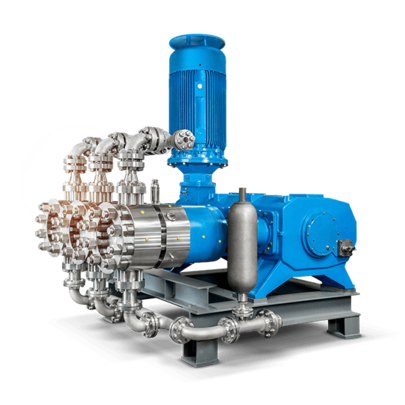

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More Details