Solution

LEWA pumps are used in a wide variety of processes for the production of biodiesel and other biofuels.

Depending on the particular application, different pumps that optimally meet the respective requirements are used:

- Conventional process for producing biodiesel with LEWA ecosmart pumps for metering of additives (up to 300 l/h, up to 80 bar, ambient temperature)

- Alternative process for producing synthetic fuels with LEWA ecoflow or LEWA triplex as high-temperature process pump for increasing reactor pressure (15 m³/h, up to 250 bar, up to 350 °C)

- Esterification of organic fats or oils with methanol in the high-pressure process with LEWA triplex, process pump as feed pump for oil or methanol, (100 to 2400 l/h, up to 250 bar, up to 100°C)

- Thermal decomposition of organic waste with a LEWA metering pump as feed pump for biomass (100 l/h, up to 320 bar), ambient temperature and a recirculation pump (250 bar, 350 °C)

- Newly developed synthesis process for the Bioliq® pilot system at KIT Karlsruhe with various LEWA metering pumps and high-temperature pumps

Areas of application

LEWA pumps in various processes for biofuel production:

Illustration

Process description

Process

Alternative process for synthetic fuel production:

Gasification of carbon-containing raw materials for the production of synthetic gas (CO+H2), which is subsequently converted into a long-chained fuel using Fischer-Tropsch synthesis. In the last process step (hydrocracking), the desired BTL fuel (synfuel) is generated at temperatures < 200°C and a process pressure up to 90 bar.

For more information about this, visit: www.bioliq.de

High pressure 2nd generation

Background

The use of biofuels offers significant advantages in comparison to fossil energy sources:

- Environmentally friendly by reducing CO2 emissions in accordance with the Kyoto Protocol

- Excess capacities of industrial agriculture can be used sensibly

- Political independence from oil states, global availability of the raw material

- Can be used with current and future engine technology, because production of a synthetic fuel can be "customized"

Biofuel production 1st generation:

Vegetable-oil-based fuels

| Source | Fuels | Targets |

|---|---|---|

Oil-bearing plants from agriculture production:

|

|

|

Biofuel production 1st generation:

Bioethanol:

| Source | Fuels | Targets |

|---|---|---|

Renewable resources

|

|

|

Biofuel production 2nd generation:

Synthetic fuels (synfuels):

| Source | Fuels | Targets |

|---|---|---|

Gasification of renewable resources, biogenic and renewable residual materials:

|

|

|

Biofuel production 3rd generation:

Hydrogen

| Source | Fuels | Targets |

|---|---|---|

| From biomass through thermochemical and microbiological processes as well as from electrolysis, powered by photovoltaic systems and wind power plants. |

|

|

Legend:

| Term | Description |

|---|---|

| Biofuels: Synfuels: BTL: GTL: CTL: CNG: LPG: ETBE: FAME: RME: | Renewable fuels and propellants Designer fuels Biomass to liquid Gas to liquid Coal to liquid Compressed natural gas Liquefied petroleum/propane gas Ethanol tertiary butyl ether Fatty acid methyl ester Raps methyl ester |

Industries

Pumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsMetering Packages and Pumps for Power Plants and Power Suppliers

LEWA supports power plant operators and power suppliers with pumps and systems for conveying, metering, and mixing different fluids. We not only provide power plants with our products, but also develop solutions for wastewater treatment plants, gas bottlers, biogas producers, regional power suppliers, and hydrogen producers.

More DetailsProducts

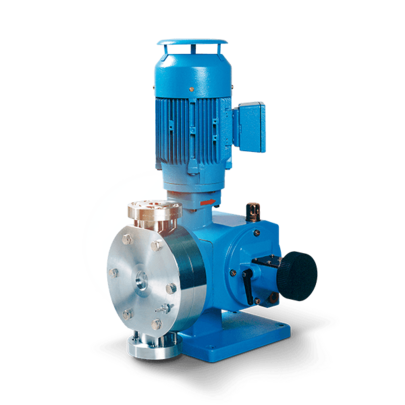

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

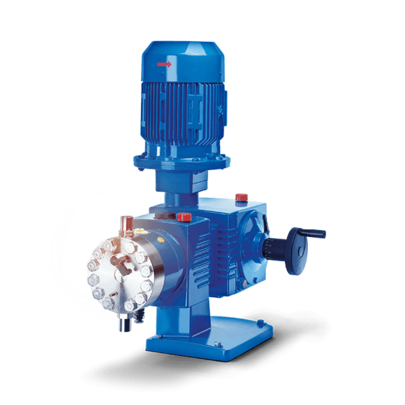

More DetailsLEWA ecosmart®: Diaphragm Metering Pumps

Experience the innovative LEWA ecosmart, a compact diaphragm metering pump offering multiplex capabilities at a competitive price. We assure the renowned LEWA quality, backed by our 70 years of market expertise. Choose LEWA ecosmart for smart metering pump solutions without compromising on quality or performance.

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

More DetailsLEWA ecodos®: Sanitary / Hygienic Diaphragm Metering Pumps

The LEWA ecodos is also offered in a sanitary/hygienic version, expertly meeting all operational standards for pharmaceutical and food production metering pumps.

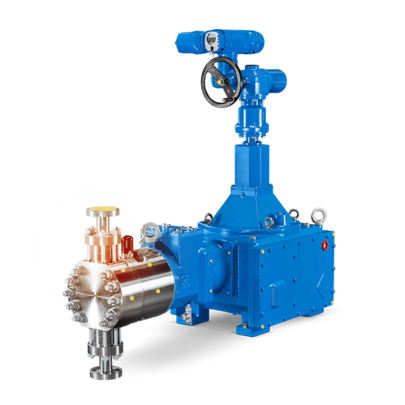

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

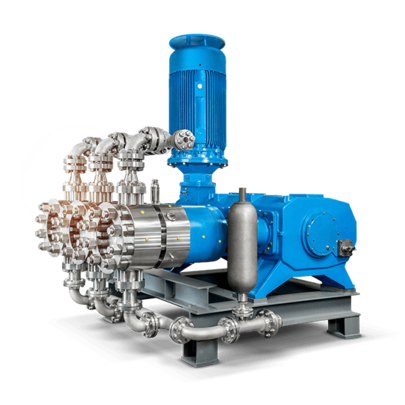

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More DetailsPomac rotary lobe pump

The flexible and economical positive-displacement pump for hygienic standard applications all the way to complex sterile applications with low-viscosity, viscous and/or shear-sensitive media.

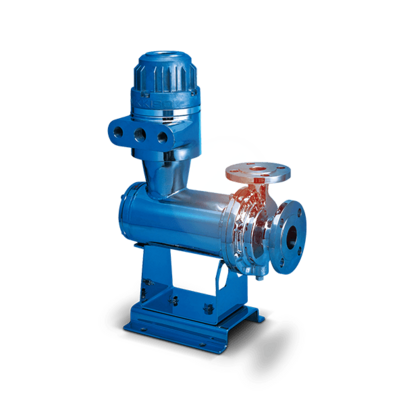

More DetailsNIKKISO NON-SEAL canned motor pump

The NIKKISO NON-SEAL canned motor pump has been designed specifically for the chemical industry. To do this, the centrifugal pump is designed in accordance with API 685.

More Details