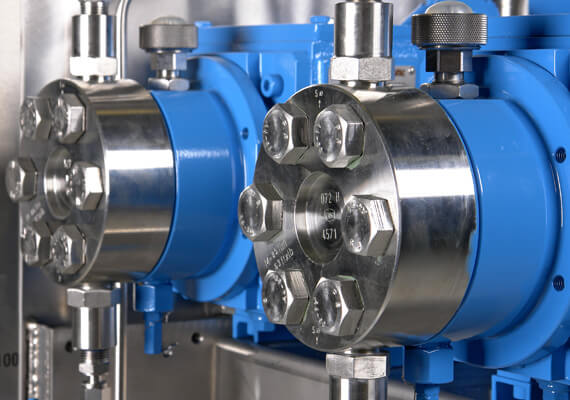

Pump synchronization

Less pulsation - more effective stand-by concepts

By synchronizing pumps, you can avoid pulsations in pipeline systems and also create effective standby concepts.

Two or more pumps are synchronized via an electronic crankshaft coupling. This means that pumps can be arranged in separate areas. Various effects are achieved via the controlled phase shift. For example, undesirable pulsations and / or resonances can be avoided. In addition, synchronization has a positive impact on the implementation of less expensive and more effective stand-by concepts.

Animated pump synchronization

Simulate different operating states of a system with and without pump synchronization in our animation. Pay particular attention to the differences in pressure pulsation in the piping system.

- Choose the lower right area the operating condition

- Follow the instructions in the pop-ups

- p

+5,86 %

Druck

-5,86 %

- Druckpulsation Anlage

- 50 % Volumenstrom Pumpe 1

- 50 % Volumenstrom Pumpe 2

- 50 % Volumenstrom Pumpe 3

+5,86 %

Druck

-5,86 %

- Druckpulsation Anlage

- 100 % Volumenstrom Pumpe 1

+5,86 %

Druck

-5,86 %

- Druckpulsation Anlage

- 50 % Volumenstrom Pumpe 1

- 50 % Volumenstrom Pumpe 2

+5,86 %

Druck

-5,86 %

- 50 % Volumenstrom Pumpe 1

- 50 % Volumenstrom Pumpe 2

+5,86 %

Druck

-5,86 %

- 50 % Volumenstrom Pumpe 1

- 50 % Volumenstrom Pumpe 2

+5,86 %

Druck

-5,86 %

- 50 % Volumenstrom Pumpe 1

- 50 % Volumenstrom Pumpe 2

Pumpensynchronisation

am Beispiel TRIPLEX G3G

Druckpulsation

Auswahl der Pumpe zur Reparatur

Auswahl der Pumpe zur Reparatur

(60° Versatz)

(60° Versatz)

(60° Versatz)

Vergleich der Druckpulsationsdiagramme

Customer benefit

The benefit of pump synchronization for systems is obvious: The technology is protected and breakdown and maintenance times are reduced. By increasing efficiency, operation of the entire system becomes more cost-effective. Lower investment costs (compare three smaller pumps with two large pumps).

Advantages:

- Better utilization thanks to operation of every pump in the lower frequency range.

- Dedicated maintenance and standby pumps unnecessary

- Lower pump life cycle costs

- Reduction of resonance and pulsations in pipeline systems

- Pumps can be switched off and on without reduction of flow rate in the overall system

- Pump synchronization is a proven and reliable LEWA technology

Features

Electronic control characteristics:

- Only one guide signal

- Automatic conversion of the guide signal and phase delay dependent on the number of pumps

- Easy transition of system to maintenance status by cutting pumps in and out

Required components:

- Frequency converter for each pump

- Encoder system for each pump

- Control unit for synchronization