Application

Maximum performance with LEWA odorizing systems. 1,000,000 standard cubic meters per hour.

Network operators transport natural gas through gigantic gas transport networks to power plants, industrial operations and, using local networks, to private households throughout Germany. At distinct hubs, large quantities of gas arrive that are subsequently funneled into different sub-networks and various directions. A gas pressure controller and measuring system ensures compliance with mandatory safety regulations and processing without a hitch. It also regulates the inlet pressure to the required outlet pressure rating. At this stage, the gas is usually odorized—a measure intended to make the unintentional escape of gas recognizable early on for everybody. Thus, safety risks and accidents can be prevented, and gas leaks can be detected in a timely manner.

At this point, LEWA comes into play. For decades, LEWA has been building systems for gas odorization and has acquired unparalleled expertise regarding processes and applications.

In 2015, a major natural gas network operator enlisted this expertise. Using an odorizing system of the OD 4200 type specifically manufactured for this customer, it was possible to develop a solution that takes the on-site conditions into account and matches the customer's difficult process requirements optimally. Tetrahydrothiophene (THT), an organic sulfur compound with an intense odor, is used as the odorant. Using the OD 4200, THT odorizes quantities of up to one million standard cubic meters per hour.

Not only is the OD 4200 the largest odorizing system ever produced by LEWA, but it is also currently the largest of its kind in Germany.

Solutions

The OD 4200 mega-odorizer. One customized solution, many benefits.

The following properties make the OD 4200 an optimal solution for the application at the hub of the gas network:

- 3 pressure-shock resistant supply containers with a capacity of 4,200 l of odorant (3 x 1,400 l)

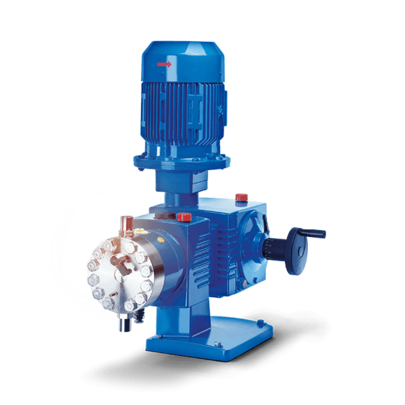

- Throughput of the required gas quantities using 4 LEWA ecoflow diaphragm metering pumps of the LDB type

- Throughput of up to 1,000,000 standard cubic meters per hour against a pressure of 70 bar

- High metering accuracy and automatic shutoff by pressure switch in case of fault

- Every 100 hours, pump 1 and pump 4 take turns as reserve pumps to prevent the valves from clogging, etc.

- Automatic report of faults to the main control unit on the customer's side

- Metering control using an electronic supervising system in the control cabinet

- 4 LEWA OCU odor control systems (controlled by PLC on the customer's part) including 4 SPU and SIOU network and power supply units and 4 EXU input cards

- Determination of the filling level using a capacitive probe

- Prevention of vessels from overflowing using a solenoid valve control card (automatic shutoff of the solenoid valve)

- Measurement of the odorant flow by 4 flow meters in the odorizing system or in the discharge line to the injection point

- Wetted parts made of 1.4404, 1.4571, 316SS steel, PTFE, perfluor elastomer or glass

- Cleaning the pump heads and the suction and pressure lines using 4 flushing systems

- In case of leakage, the escaping odorant is caught in a trough, which is tested in accordance with the steel trough directive

- Activated carbon filters for odor control in the ventilation lines of the vessels (including a three-way valve for the connection of a vapor return line)

- Flame protection filters as protection against explosions in the air venting line

OD 4200 installation dimensions

| L [m] | W [m] | H [m] |

|---|---|---|

| 4,50 | 1,95 | 3,10 |

Background

Why is natural gas odorized? What requirements does the odorant have to meet?

Natural gas odorization is an important safety measure, not just for gas purchasers and customers. Formerly used city or cokery gases had a strong intrinsic odor and rarely required odorization. Meanwhile, the commonly used natural gas is cleaned and almost odorless. In order to be able to immediately detect leakage in the gas network, the natural gas odorization is mandatory as a safety measure. The gases added during the odorization generate specific warning odors. This prevents the formation of explosive gas/air mixtures, which are highly dangerous.

The odorants used in the odorization of natural gas must fulfill special safety requirements. Their odor must be perceptible even at a high dilution, and unmistakably induce the association with gas leakage. The odorant must therefore smell unpleasant and distinctive.

In Germany, volatile organic sulfur compounds are frequently used as odorant. Their typical savor is evocative of the smell of rotten eggs. Often the odorless saturated sulfur heterocycle tetrahydrothiophene (THT) is used in concentrations of 12 to 25 mg/m³. Frequently, also mercaptan mixtures are in use.

There are also odorants free of sulfur. Unlike the odorization with the sulfur-containing substances THT or Mercaptan, sulfur-free odorants have the advantage that no additional sulfur oxides are formed during the combustion of natural gas. Examples of sulfur-free odorants are mixtures of ethyl acrylate (> 50%), methyl acrylate and 2-ethyl-3-methylpyrazine. These substances produce a solvent-like odor which, according to a study by the DVGW, is still associated with natural gas by operators. But, the effectiveness of these substances is still controversial.

(Source: Wikipedia.de, "Odorierung", 10/2016).

Industries

Gas Odorization with LEWA Pumps and Metering Packages

Natural gas, oxygen, and nitrogen are odorless but potentially dangerous. This is why these gases are "odorized" with as strong a smelling substance as possible. For more than 40 years, LEWA has been developing systems for the odorization of gases such as natural gases, biogases, and liquefied gases. This process is enormously important, so the odorizing system has to operate precisely and reliably.

More DetailsMetering Packages and Pumps for Power Plants and Power Suppliers

LEWA supports power plant operators and power suppliers with pumps and systems for conveying, metering, and mixing different fluids. We not only provide power plants with our products, but also develop solutions for wastewater treatment plants, gas bottlers, biogas producers, regional power suppliers, and hydrogen producers.

More DetailsProducts

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA Odorizing Systems

LEWA has been building odorizing systems for gases such as natural gas, oxygen, nitrogen, and carbon dioxide for more than 40 years. LEWA odorizing systems meter the odorant in question reliably, proportionally, and economically.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details