"The production of sulfate granules for chemical water treatment in a continuous process is a very delicate matter," says Torsten Moller, sales representative for LEWA in Sweden. Moller is managing the project with the customer. During the dilution of concentrated sulfuric acid, it reacts strongly with water. In the static mixing installation, temperatures of up to 300 °C can suddenly arise, while the aggressiveness of the acid steadily increases. "In the event of failures, defects or unplanned shutdowns of the plant, backflow from the mixer into the pumps can occur," Moller added. "The units must therefore be able to withstand the dangerous acid and high temperature as well as pressure fluctuations and must not have vulnerable seals."

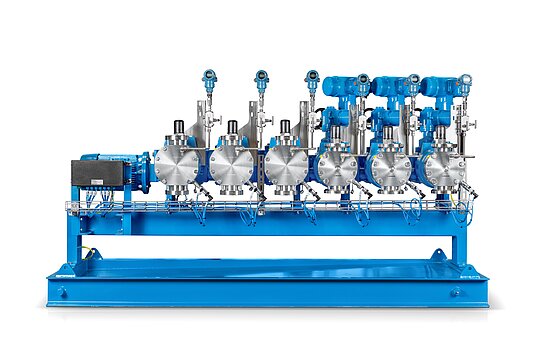

At the Swedish production site there had been already two combined LEWA pump systems in use, each with five pump heads, for the production of sulfate granules since 1989 and 1990, respectively. The chemical company was extremely satisfied with these for more than 30 years. However, the Leonberg-based pump specialist no longer carries these older models in its product range, so the corresponding spare parts are no longer available. "The customer was convinced of the reliability and high functionality of the LEWA units based on their many years of experience, so I suggested replacing the discontinued models with new pumps from the same manufacturer to ensure production for the coming decades," Moller says. "This also gave us the opportunity to significantly reduce pulsation and therefore the size of the pulsation dampers on the new pumps."

Optimal synchronization of the six pump heads over 360 degrees

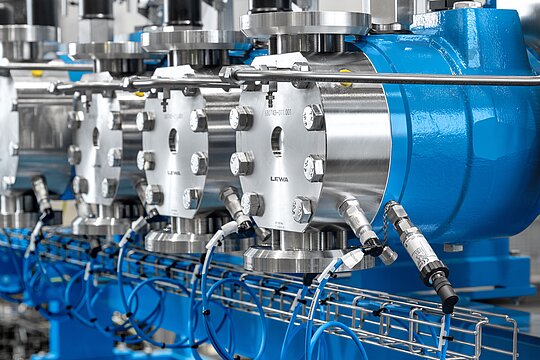

Especially for this highly sensitive application, the pump specialist developed a LEWA ecoflow combination pump with a total of six M900 pump heads: three each for the sulfuric acid and the process water. "In order to safely pump the 85 to 98 percent sulfuric acid, the units have to be hermetically tight," Moller explains. "The ecoflow range meets this requirement." For the acid pump, the choice was made for the LDE3 model, which is made of highly corrosion-resistant Hastelloy so that it can withstand the aggressive medium. The smaller LDD3 model is sufficient for the process water pump. To avoid problems in the event of backflow of diluted sulfuric acid from the mixer into the pumps, the customer chose 316L stainless steel for the material, since it has good acid resistance. In order to be able to flexibly dilute the sulfuric acid depending on the end product, the LDD3 features electrical stroke length setting from 0 to 30 mm.

To ensure that the two media are conveyed into the static mixer without a hitch and that strong chemical reactions do not occur, a constant flow rate must be ensured. "To keep pulsation as low as possible, we shifted the phases of the individual pump heads of a medium by 120 degrees each," explains Moller. "In addition, the frequencies of the LDD3 and the LDE3 differ by 60 degrees." The phase shift of 0/120/240 degrees for the process water and 60/180/300 degrees for the sulfuric acid results in nearly perfect pump synchronization over 360 degrees. Because of how well the six pump heads work together, the new system manages with significantly smaller pulsation dampers than before.

LEWA Smart Monitoring ensures continuous production

As the heart of the plant, the new LEWA combination will ensure the continuous production of sulfate granules. So that nothing is left to chance, the units were equipped with innovative LEWA Smart Monitoring. The system not only enables precise control of the pump, but also automatically monitors all key operating figures around the clock and detects malfunctions and process deviations in real time. Due to the combination of integrated sensor technology and compatible evaluation software, the system seamlessly records changes in pulsations or signs of wear on the pump valves, for example. This produces up to 13,000 values per second, which the algorithm uses to calculate meaningful key figures. This also makes it possible to trace which components are causing the detected deviations. "For example, if a valve stops working properly, maintenance personnel immediately know which valve in the pump is involved," Moller explains. "It is no longer necessary to open all twelve valves individually and check them manually, which saves a lot of working time."