Metering systems from LEWA

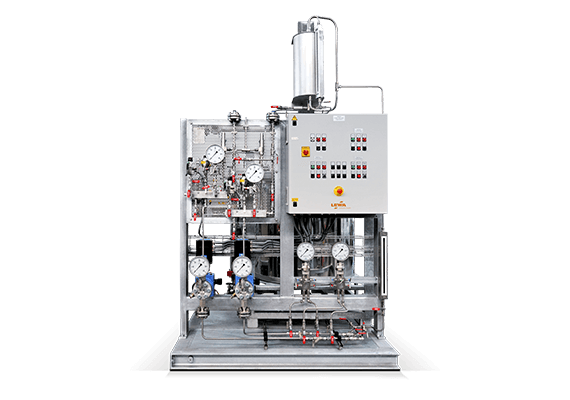

A custom-designed system for every application.

Metering, cooling, heating, controlling, regulating – our customer-specific metering systems ensure the interaction of the pump, instrumentation, and accessories. LEWA takes your application and specification, your interface logic, and your ideas into consideration and implements them accurately and comprehensively.

We handle all the preliminary planning, on-site data collection, and testing and calculation of the secondary systems and pressure conditions. The metering system or filling system is integrated into your new or existing plant.

Good reasons to choose a metering system from LEWA

LEWA designs and builds turnkey metering systems in closed loop control with monitoring and plausibility testing equipment for various production processes.

Years of experience for perfect metering system designs

We have many years of experience in mixing liquids of different viscosities at various temperatures and pressure levels. And we use this knowledge when creating customer-specific metering systems for companies in various industries.

Experts in metering and injection processes

Our process expertise, which creates perfect results in metering and injection processes, is in demand across the world. We also have a wealth of experience in dealing with required dwell times, idle periods, post-mixing, and heat addition and removal for process reactions.

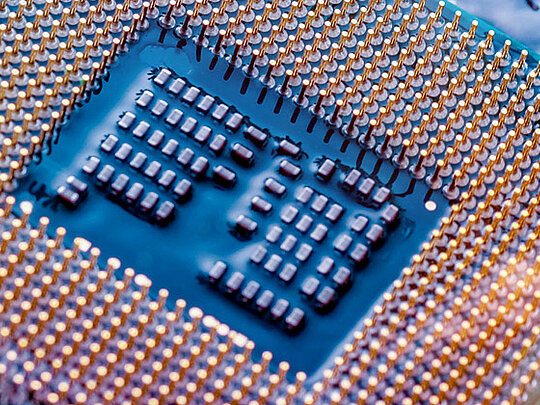

The control system as the intelligence center of the metering system

Precise, fast control of the metered flow in the case of changes to setpoint values or other deviations ensures that the end product is always of top quality. This is achieved by a control system developed by LEWA, which continuously monitors the plausibility of set values and actual values. Our systems are equipped with PLC interfaces to Profibus DP, CAN, MOD-Bus or Ethernet, for example.

LEWA pumps are at the heart of our systems

We prefer to use our own diaphragm metering pumps manufactured in-house for our metering, mixing and filling systems. These are characterized by continuous stroke length and speed adjustment, ensuring an accurate and wide adjustment range. Pressure has virtually no influence on the metering characteristic, which makes monitoring easy and precise. What's more, high metering accuracy paired with a flow measurement and monitoring system ensures reliable and reproducible production.

Integration of third-party components

Our expertise also helps when it comes to integrating other pump types, provided that these lead to a better result based on the application, the flow rate or the composition of the pumping fluid: All components are adapted to meet your requirements perfectly.

Compliance with all international standards and norms

We clarify all national and international standards and regulations, as well as customer-specific and product-specific requirements, during the design phase. Our systems are developed in accordance with TÜV, API, and other specifications.

LEWA supplies metering systems that meet customer requirements perfectly. To achieve this, we use our tried-and-tested modular system with various components in line with the needs of the specific application.

| Basic components | Additional components |

|---|---|

|

|

Options

Intellidrive technology

Using the highly-dynamic servomotor, you can adjust the stroke of the pump to the requirements of your system and your process.

Different drive types

We flexibly react to environmental conditions: Pumps in our Chemical Injection Packages are driven by electric (solar energy), compressed air, gas or diesel engines.

CIP/SIP capability for pharma applications

For applications in pharmaceutical, cosmetic and food industry, we offer our pumps and systems in sanitary & hygienic design, which fulfils all standards and norms.

Customized valves

LEWA uses numerous special types of valves such as specially hardened valves for liquified gases or valves with minimal dead space for the food and pharmaceutical production.

Pipelines according to all standards

The piping of our systems can be designed according to different standards: dairy pipe, DIN, ANSI, JIS, Ermeto, Swagelok, Aminco HP, Tri-Clamp etc.

Examination by experts and authorities

We also gladly provide performance diagrams and certificates of static pressure tests also by TÜV, Germanischer Lloyd’s, Lloyd’s R. of S. or other authorities.

Global commissioning

With our global service network, we take your equipment into operation and provide technical service directly at your location - both onshore and offshore.

Complete documentation

Receive supporting documents and certificates, including the operating instructions, as well as design and test details in different languages.

Testing, acceptance and inspection

We make sure that everything works: LEWA offers numerous services, including factory acceptance test (FAT) at the manufacturing site or at your site (SAT), NDT and PMI.

Technical data

Thanks to our tried-and-tested modular system plus our extensive portfolio of pumps, we can create custom systems that always meet customer requirements exactly.

Performance data

| Discharge pressure, min. [bar] | Discharge pressure, max. [bar] | Flow rate, min. [ml/h] | Flow rate, max. [ml/h] | Operation, min. [°C] | Operation, max. [°C] | Viscosity [mPa∙s] |

|---|---|---|---|---|---|---|

| 0 | 1200 | 10 | 180 | -40 | +400 | < 1500000 |

Installation dimensions*

We consistently ensure that the footprint of our systems is kept to a minimum. Pumps, gear units, motors, and piping always have the most compact design possible.

| L [m] | W [m] | H [m] | Segment weight** [max. to] | Vessel [m³] |

|---|---|---|---|---|

| 10.0 | 3.5 | 4.0 | 32 | 50 |

* Installation dimensions are approximate

** Larger systems in modular design; other limitations may be imposed by transport restrictions and installation dimensions approved by the customer.

Industries

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsGas Odorization with LEWA Pumps and Metering Packages

Natural gas, oxygen, and nitrogen are odorless but potentially dangerous. This is why these gases are "odorized" with as strong a smelling substance as possible. For more than 40 years, LEWA has been developing systems for the odorization of gases such as natural gases, biogases, and liquefied gases. This process is enormously important, so the odorizing system has to operate precisely and reliably.

More DetailsPumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Plastics Industry

We offer you special expertise for all compounding processes in the plastics processing industry (addition of waxes, flame retardants, and lubricants). Contact our experts! We're happy to give you advice about metering and pumping solutions for the plastics industry such as in polyethylene processing.

More DetailsPumps and Systems for the Manufacture of Detergents and Cleaners

LEWA offers continually operating, formula-controlled systems for the manufacture of household and industrial cleaners in all commercially available surfactant concentrations – from raw product to end product. Contact our experts and let us advise you – we will work with you to configure pumps and systems for the manufacture of detergents and for the production of other cleaners.

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsPumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsMetering Packages and Pumps for Power Plants and Power Suppliers

LEWA supports power plant operators and power suppliers with pumps and systems for conveying, metering, and mixing different fluids. We not only provide power plants with our products, but also develop solutions for wastewater treatment plants, gas bottlers, biogas producers, regional power suppliers, and hydrogen producers.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsPumping solutions for mining and metal and mineral processing

From the explosives manufacturing, ore extraction and metal and mineral recovery to effluents treatment and final product finishing, our solutions have helped our clients to save energy and consumables while keeping high operational safety and low cost of ownership.

More DetailsApplications

Additive metering for plastics

LEWA provides system solutions for metering additives for plastics. Ask our additive metering experts for more information!

More DetailsAmine treatment

At LEWA, you receive pumps and systems for amine treatment in power plants. Ask our experts for more information.

More DetailsDownstream processing

LEWA systems and gradient mixers are used in downstream processing of chemicals and biotechnology. We look forward to receiving your inquiry!

More DetailsFabric softeners

At LEWA, find out about plants and systems for fabric softener production. Our experts are happy to talk to you about your custom solution!

More DetailsPolymerization

LEWA manufactures metering pumps and metering systems for polymerization which optimally meet the necessary requirements. We are happy to help.

More DetailsExtruder blowing agents

Precise metering of blowing agents into extruders with LEWA systems. We provide you insights on the metering accuracy and process optimization solutions from LEWA.

More DetailsExtraction with supercritical fluids

Processes with supercritical fluids in pharmaceutical, food and beverage industries. Ask our experts for more information!

More DetailsPharmaceuticals production

Metering pumps and metering systems must meet the following demands of pharmaceutical production.

More DetailsPharmaceutical spray drying

LEWA provides accurate and efficient diaphragm metering pumps for pharmaceutical spray drying. Consult us!

More DetailsPhosphate precipitation

Metering of phosphate precipitants with diaphragm pumps in sewage treatment plants. We provide you with tailored advice and work out concepts for you.

More DetailsMetering flavoring agents

Metering of flavoring agents by LEWA metering systems using the process of brewing alcohol-free beers as an example.

More DetailsMetering of silane

LEWA systems meter any silane type reliably, precisely as well as in constant consistency and purity, regardless of chemical or physical attributes or process requirements.

More DetailsProduction of biofuels

Biofuels are produced using metering and process pumps from LEWA in the remote-head design. Learn more about these and other applications!

More DetailsFlue gas cleaning by means of metering sulfur | LEWA

When using an electrofilter for flue gas cleaning, metering sulfur improves the filtration efficiency. LEWA has the solution!

More DetailsProduction of gelatine

In the production of gelatin and in the fabrication of gelatin products, LEWA pumps and systems are used. We would be happy to give you more information!

More DetailsGas odorization in the natural gas distribution grid

At hubs in the gas distribution network, big amounts of natural gas are forwarded. LEWA odorization unit OD 4200 is able to odorize gas amounts of up to 1.000.000 m³/h.

More DetailsBattery test facilities

LEWA supplies metering systems for the testing ofelectric vehicle batteries on battery test stands - for example with the aid of a water-glycol mixture. Find out more here!

More DetailsAdding antistatic agents to improve the conductivity of fuel

Antistatic additives or antistatic agents prevent the electrostatic charging of fuels which occurs due to the friction in the pipelines during transport. Use LEWA metering systems for this application!

More DetailsAdjustment of cleaning agent concentration for electronic components

LEWA metering systems adjust concentrations of cleaning agents for the immersion cleaning of electronic components.

More DetailsProduction of creams

With its metering systems and diaphragm pumps, LEWA offers the right solution for recipe-compliant production of creams.

More DetailsSulfuric acid injection in copper heap leaching

LEWA process pumps are used to reinject sulfuric acid at 98% into the main pipelines that go to the heap leach sprinklers.

More DetailsDispersing

With the diaphragm metering pumps and streamlined suspension valves, LEWA offers the suitable solution for the metering of fluids with solid particles.

More DetailsAdditive dosing for fuels

LEWA supplies both diaphragm metering pumps and process diaphragm pumps for additive dosing in fuels. We provide you with the right pump and advice for your application.

More DetailsDownloads

LEWA Dosier-und Mischanlagen - komplette Lösungen aus einer Hand. (DE)

In vielen verfahrenstechnischen Produktionsanlagen spielt das Dosieren und Mischen von Flüssigkeiten als Verfahrensschritt eine wichtige Rolle, der für die Qualität des Endproduktes mit verantwortlich ist.

4 MB

| pdf |

18.02.2022

LEWA metering and mixing systems-complete solutions from a single source. (EN)

In many manufacturing plants, the metering and mixing of liquids plays an important role as a

procedural step that ensures the quality of the end product.

4 MB

| pdf |

18.02.2022