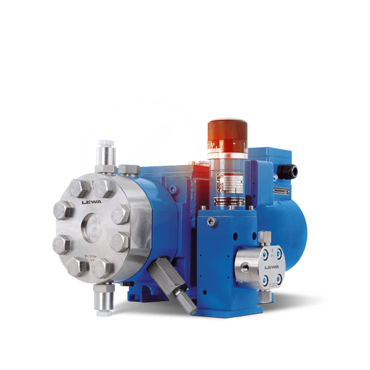

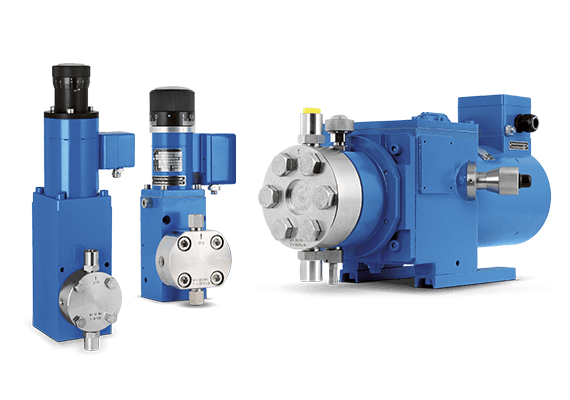

LEWA MAH, MBH and MLM micro-metering pumps

Smallest flow rates, highest efficiency.

In the demanding sectors of the oil and gas industry, gas odorization, and energy production, precision in metering minuscule fluid amounts is critical, often adjusted to variable reference values.

The LEWA MAH, MBH, and MLM micro-metering pumps are engineered for such specialized requirements. These pumps boast an exceptionally broad control range for ultimate metering flexibility, ensuring precise small flow rates. Equipped with four solenoid power sizes, they cater to a comprehensive spectrum of applications.

Additionally, the series offers smaller pump types with non-Ex-protected solenoids for operations requiring higher pressure. Coupled with two specially designed control systems, these micro-metering pumps from LEWA adapt seamlessly to a multitude of specific tasks, embodying efficiency and versatility in micro-metering technology.

Key Benefits of LEWA Micro-Metering Pumps: Precision & Flexibility

LEWA micro-metering pumps excel as precision metering devices, featuring a hydraulically actuated metal diaphragm coupled with a solenoid actuator for unmatched accuracy and control.

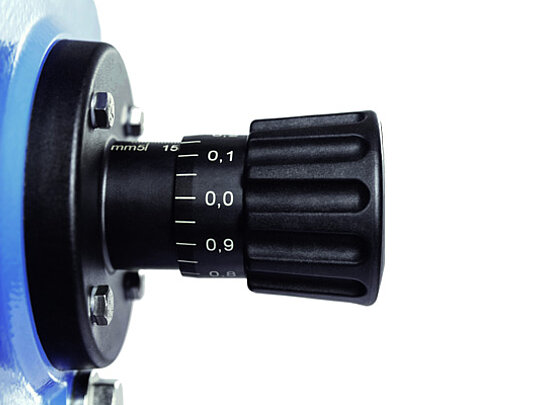

Extremely large adjustment range

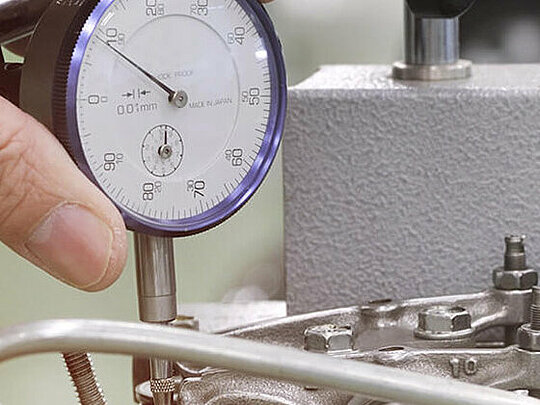

Precision is our strength: LEWA micro-metering pumps provide maximum metering flexibility through an extremely large control range of 1:1000. This allows us to fulfill the most stringent requirements for sensitive metering tasks in various industries.

Safety and reliability in extreme operating states

For us, safety and reliability comes first: The pump is not subjected to damage, even after operating errors occur or in extreme operating states. We offer maximum protection for user and machine through built-in safety mechanisms - not only when excess primary pressure is present, but also when the pressure or suction line is closed.

Low maintenance and service life costs

LEWA micro-metering pumps have minimal life cycle costs. They achieve this advantage compared to other micro-metering pumps with high energy efficiency, low operating and maintenance costs and an extremely long lifetime of the diaphragm and process valves.

Vacuum sealed

LEWA micro-metering pumps are not only leak-proof, but also absolutely odor-tight. This ensures that no contamination can occur.

Suitable for virtually all fluids

The micro-metering pumps are suitable for many different fluids. Whether they are dangerous, toxic, abrasive, viscous, environmentally harmful or sensitive fluids, the user-specific configuration always gives you the correct diaphragm metering pump.

Integrated pressure relief valve (only for MLM)

A pressure relief valve in the hydraulic part of the diaphragm pump prevents potential overload situations in operation. This valve is individually adjustable and can therefore be adapted to different operating situations.

Superior metal diaphragm technology

The metering pumps are equipped with sophisticated metal diaphragm technology, which enables discharge pressures up to 500 bar. At the same time, they still meter very precisely at an accuracy of ± 1%.

Dry-run safe

The pumps are dry-run safe. No sliding seals or packages are inserted. This guarantees the highest process safety.

Compliance with common standards

LEWA micro-metering pumps fulfill common standards such as DVGW G280. They are also explosion-protected up to EX-Zone 1.

Features of LEWA Micro-Metering Pumps: Engineered for Precision

MAH series without explosion protection

For non-hazardous applications, we manufacture our MAH-series microflow pumps also without explosion protection. Thus we can offer you even more economical micro metering pumps.

Specially adapted control unit

Rely on precision and our experience: We offer you several specially adapted controls for hazardous and non-hazardous zone (for example, MPM, MSG, OLK, OKR.)

Flow meters

A pump is only as good as its control and regulation system. That's why we provide precise flow meters in different variations for accurate control.

Special design materials

If the process demands it, wetted parts such as pumps heads and valves will be made of special materials such as stainless steel 316/316L (1.4401/1.4404), Hastelloy or Duplex steel and PVC.

Heating and cooling jacket

With heating and cooling jackets, our pumps are suitable for almost any temperature and can convey fluids at low temperatures or extreme heat.

Customized valves

LEWA uses numerous special types of valves such as specially hardened valves for liquified gases or valves with minimal dead space for the food and pharmaceutical production.

Integration into process control systems

The signal acquisition of process control systems is achieved analogously or digitally. Flow rate is adjusted via electric or pneumatic stroke adjustment, alternatively by motor drive (FU).

Complete documentation

In the process of documentation, we consider your requirements and provide inspection records, print samples, diagrams of output characteristics and registration papers on request.

Technical Data

The LEWA series M micro-metering pump is available in numerous performance and size variants. We are happy to assist you in selecting the suitable pump for your application.

Drive unit data

With the various micro-metering pump variants MAH, MBH and MLM – available with or without explosion protection – we cover flow rates from 0.01 to 55 l/h and discharge pressures from 4 to 560 bar.

| Type | Without Ex protection | With Ex protection | ||

|---|---|---|---|---|

| Flow rate [l/h] | At max. pressure [bar] | Flow rate [l/hr] | At max. pressure [bar] | |

| MAHmin. | 0.01 | 50 | 0.01 | 30 |

| MAHmax. | 1.6 | 6 | 1.6 | 4 |

| MBHmin. | - | - | 1.7 | 50 |

| MBHmax. | - | - | 2.4 | 16 |

| MLMmin. | - | - | 0.5 | 560 |

| MLMmax. | - | - | 55.0 | 5.7 |

Installation dimensions

Various sizes for any intended use: MAH, MBH and MLM differ significantly in their dimensions, MAH and MLM are each available in two different sizes.

| Type | L [mm] | B [mm] | H [mm] |

|---|---|---|---|

| MAH 3 | 102 | 110 | 260 |

| MAH 5/8 | 102 | 120 | 260 |

| MBH 8/10 | 155 | 195 | 510 |

| MLM 15/40 -3 | 450 | 140 | 260 |

| MLM 15/40 -20 | 450 | 180 | 260 |

Industries

Pumps and Packages for the Production of Crude Oil and Natural Gas

LEWA has been your expert in pumps and packages since the 1950s. With us, you get everything from a single source: Our custom-built packages are used all around the world for offshore crude oil and natural gas production. From China to the United Arab Emirates, strong partners rely on our expertise for crude oil exploration applications.

More DetailsGas Odorization with LEWA Pumps and Metering Packages

Natural gas, oxygen, and nitrogen are odorless but potentially dangerous. This is why these gases are "odorized" with as strong a smelling substance as possible. For more than 40 years, LEWA has been developing systems for the odorization of gases such as natural gases, biogases, and liquefied gases. This process is enormously important, so the odorizing system has to operate precisely and reliably.

More DetailsPumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsPumps and Metering Packages for the Petrochemical Industry

We have supplied durable pumps and metering systems for applications such as the hydrocracking process for over 50 years. Petrochemicals generate starting products for the manufacture of plastics, pharmaceuticals, colorants, detergents, and other products. Contact our experts and allow us to provide you with detailed information about metering and pumping solutions for the hydrocracking process!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsPumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsMetering Packages and Pumps for Power Plants and Power Suppliers

LEWA supports power plant operators and power suppliers with pumps and systems for conveying, metering, and mixing different fluids. We not only provide power plants with our products, but also develop solutions for wastewater treatment plants, gas bottlers, biogas producers, regional power suppliers, and hydrogen producers.

More DetailsPumps and Metering Systems for Other Industries

LEWA offers customized solutions and references for almost all industries in which processes require exact metering or the reliable conveyance of fluids. As specialists in fluid handling, we of course also have experience in areas outside of our key markets.

More DetailsApplications

LEWA MAH, MBH, MLM micro-metering pumps can be found in numerous applications:

Proportional metering of fluids in variable main currents, e.g. inline blending, natural gas odorization, additive supply, regulation of physical material values to main currents or large volumes with a good mixture in higher-level control circuits, e.g. coloring, viscosity, pH values.

Metering of silane

LEWA systems meter any silane type reliably, precisely as well as in constant consistency and purity, regardless of chemical or physical attributes or process requirements.

More DetailsContinuous metering of extremely small quantities with LEWA intellidrive

Minimum flow rates down to 1 ml/h: With LEWA intellidrive technology, we already have created solutions for many applications with very small flow rates.

More DetailsOil-free CO2 cooling with LEWA pumps

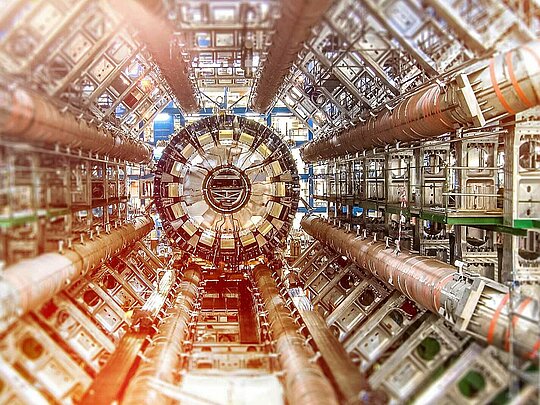

LEWA diaphragm metering pumps provide a constant oil-free CO2 cooling of silicon sensors in particle physics research center CERN.

More DetailsDilution of emulsifiers

With its metering systems and diaphragm pumps, LEWA offers the right solution for recipe-compliant emulsifier dilution.

More DetailsExtracting omega-3 fatty acids using supercritical CO2

LEWA offers optimum pump solutions for these processes, which perform their tasks safe, permanently reliable and efficiently

More DetailsDispersing

With the diaphragm metering pumps and streamlined suspension valves, LEWA offers the suitable solution for the metering of fluids with solid particles.

More DetailsDownloads

LEWA Micrometering pumps (USA)

Micro-metering pumps with diaphragm technology for metering fluids in laboratories and test centers.

1 MB

| pdf |

18.02.2022

LEWA Mikrodosierpumpen (DE)

Mikrodosierpumpen mit Membrantechnologie für die Dosierung von Flüssigkeiten in Labor und Technikum.

2 MB

| pdf |

18.02.2022

LEWA Micrometering pumps (EN)

Micrometering pumps with diaphragm technology for metering fluids in laboratories and test centers.

2 MB

| pdf |

18.02.2022