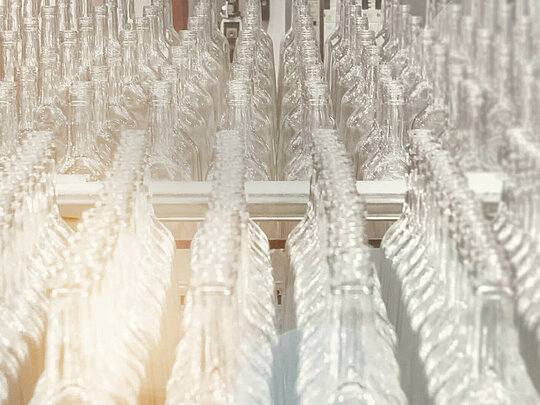

Food & Beverage Industry

Precise System Solutions for Hygienic Processes with LEWA

Process integrity, recipe compliance, and product reliability are fundamental requirements in food technology, with hygienic considerations and cleanability at the forefront. It is crucial that the process remains sealed to prevent any contamination of the media at every production stage.

LEWA delivers precise system solutions tailored to the needs of the food and beverage industry for critical processes such as homogenization, mixing, and filling. Our pumps and systems ensure your production meets the highest standards of hygiene and efficiency

Areas of Application for LEWA Pumps and Systems in the Food Industry

Our products allow you to convey and meter, as well as process and homogenize.

| Product applications | Typical tasks | Examples of subindustries |

|---|---|---|

| Areas of applications in the food and beverage industry | Conveying low-viscosity and viscous media |

|

| Proportionally metering additives, e.g., flavorings, acids, vitamins, color pigments, in a precise and controlled manner |

| |

| Mixing/dispersing/homogenizing |

| |

| Filling |

| |

| Tempering |

| |

| Spraying for drying and preparing food under medium to high pressure |

| |

| Treating with SO2, O2, and preservatives |

| |

| Extraction, e.g., with CO2 |

| |

| Coatings |

|

Our pumps and systems convey, meter, and process a multitude of substances for the production of foods and beverages.

| Substance | Examples of end products | |

|---|---|---|

| Typical conveyed, metered and processed substances | Gelatin, chocolate |

|

| Sugar, glucose mixtures |

| |

| Waxes, wetting agents |

| |

| Oils |

| |

| Vegetable oils, vinegar, (oil in water emulsions) |

| |

| Enzymes |

| |

| Yogurts, creams |

|

Solutions in the Food and Beverage Industry

Illnesses and allergies from contaminated food are tragically common, highlighting the critical need for stringent food safety, recipe compliance, and process integrity. LEWA equipment meets these needs by enabling precise food processing and homogenization, ensuring the highest quality for your customers.

Our products feature hermetic seals that prevent cross-contamination and abrasion-related contamination, while their optimal cleanability upholds sanitary conditions. The hygienic design of our systems complies with both national and international standards, underscored by EHEDG certifications for relevant products.

LEWA's expertly engineered pumps and process-safe systems are specifically designed for tasks like homogenization, ensuring consistent recipe adherence and dependable product quality that is both reproducible and cost-effective over time.

In collaboration with technical commissions, end users, and regulatory bodies, we actively participate in the creation and revision of industry guidelines. This partnership ensures our solutions always meet the evolving needs of our customers and that our expertise remains current

Advantages of the LEWA Pumps and Systems in the Food & Beverage Industry

High end pumps, equipment and systems

We deliver high-end pumps integrated into complete systems and units for your specific applications. In doing so, we of course rely on the tried-and-tested LEWA quality.

Easy to clean

An especially important advantage for pharmaceutical and food industry is that our systems can be quickly and easily cleaned with cleaning chemicals or hot steam.

Minimization of unproductive times

Our systems are extremely reliable and low maintenance. Thus, you can get the maximum out of your production and avoid costly downtime.

Sanitary & hygienic design

Highly polished surfaces and a minimal dead space construction are the basis for a system design that meets all the industry's hygienic standards.

Economic solutions

We always deliver economic pumps, systems and units with minimized energy consumption, high efficiency, low maintenance and a long lifetime.

Tried and tested modular system

We design our systems and units in modular design with numerous engine and pump head combinations for different applications.

Special materials

On request, we can build systems with special materials such as Hastelloy, titanium, duplex stainless steel or further materials. If you are interested, please contact our product manager.

Patented sandwich diaphragm

Our patented diaphragm metering pumps use metal or PTFE sandwich diaphragms with Diaphragm Protection System (DPS) for maximum operational safety.

International standards

LEWA pumps, systems and units are compliant with major international standards such as DVGW G280, WHG, PED, ISO 9001, ASME, ATEX and TA-Luft. Of course, you can also define your own standards.

Applications

Caustic soda production

At LEWA, find out about custom plants for producing and diluting different bases like caustic soda. Ask our experts for more information.

More DetailsExtraction with supercritical fluids

Processes with supercritical fluids in pharmaceutical, food and beverage industries. Ask our experts for more information!

More DetailsChemical metering in high-pressure cleaning systems

LEWA metering and process diaphragm pumps meet the specific demands for the production of melamine (trimerization of urea). Consult us!

More DetailsProduction of edible oil

LEWA diaphragm metering pumps are used for the production of edible oil. We are happy to assist with your individual production process.

More DetailsPharmaceutical spray drying

LEWA provides accurate and efficient diaphragm metering pumps for pharmaceutical spray drying. Consult us!

More DetailsMetering flavoring agents

Metering of flavoring agents by LEWA metering systems using the process of brewing alcohol-free beers as an example.

More DetailsButter production

In order to sustain consistent quality of spreadable butter, ingredients like rapeseed oil, water, and brine are metered flexibly and fully automatically with ecoflow pumps.

More DetailsHomogenization of milk

With LEWA homogenization systems, producers of dairy products can achieve uniform particle size, moisture, and color, for example, in infant formula, and prevent the milk concentrate within it from creaming.

More DetailsProduction of gelatine

In the production of gelatin and in the fabrication of gelatin products, LEWA pumps and systems are used. We would be happy to give you more information!

More DetailsFiltration with diatomite

When beer, wine and fruit juices are filtered, the LEWA ecodos sanitary/hygienic pump is used, which is designed for handling diatomite suspensions.

More DetailsYoghurt production

Pomac rotary lobe pumps are used for transferring yogurt products to the filling station. We will be happy to give you more information about industrial yogurt production!

More DetailsHigh purity systems

Pumps and high purity systems from LEWA are a tried-and-tested solution in the pharmaceutical & biotechnology industry. We are happy to assist with your individual high purity system.

More DetailsDilution of emulsifiers

With its metering systems and diaphragm pumps, LEWA offers the right solution for recipe-compliant emulsifier dilution.

More DetailsExtracting omega-3 fatty acids using supercritical CO2

LEWA offers optimum pump solutions for these processes, which perform their tasks safe, permanently reliable and efficiently

More DetailsProducts

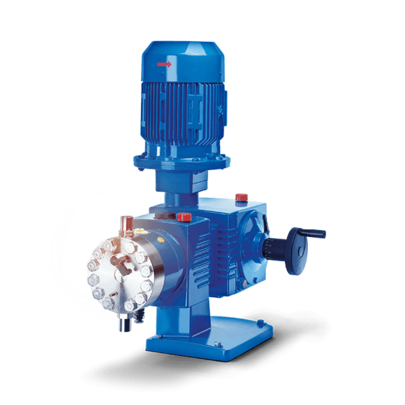

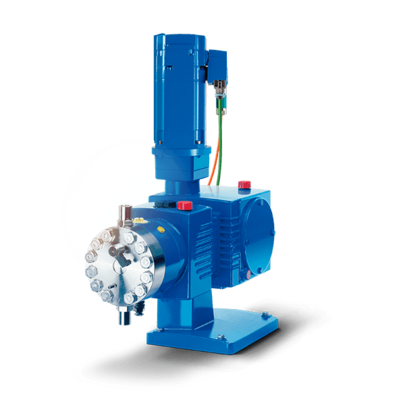

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

More DetailsLEWA ecoflow®: Hygienic Diaphragm Metering Pumps

Discover the LEWA ecoflow® in its hygienic version, designed for sanitary applications. This versatile metering pump maintains its renowned all-around performance while meeting the stringent hygienic standards required in pharmaceutical and food production industries.

More DetailsLEWA ecoflow® Packed Plunger Metering Pumps

Opt for the LEWA ecoflow packed plunger metering pump, a robust and reliable choice for hassle-free fluid metering. Available in multiple models to suit diverse processes, it's the metering pump trusted by industry leaders for consistent performance.

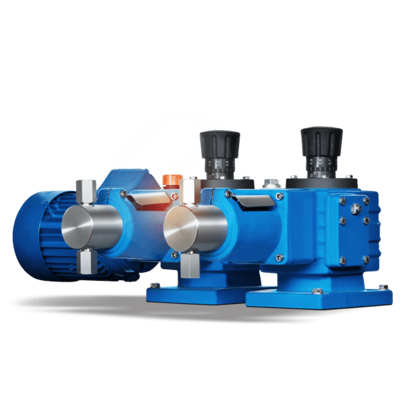

More DetailsLEWA ecosmart®: Diaphragm Metering Pumps

Experience the innovative LEWA ecosmart, a compact diaphragm metering pump offering multiplex capabilities at a competitive price. We assure the renowned LEWA quality, backed by our 70 years of market expertise. Choose LEWA ecosmart for smart metering pump solutions without compromising on quality or performance.

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

More DetailsLEWA ecodos®: Sanitary / Hygienic Diaphragm Metering Pumps

The LEWA ecodos is also offered in a sanitary/hygienic version, expertly meeting all operational standards for pharmaceutical and food production metering pumps.

More DetailsLEWA intellidrive®:Mechatronic Diaphragm Metering Pump Technology

Customize both suction and discharge strokes to fit your precise specifications with the LEWA intellidrive® diaphragm metering pump. This technology allows you to individually shape pumping characteristics, ensuring optimal metering for your applications.

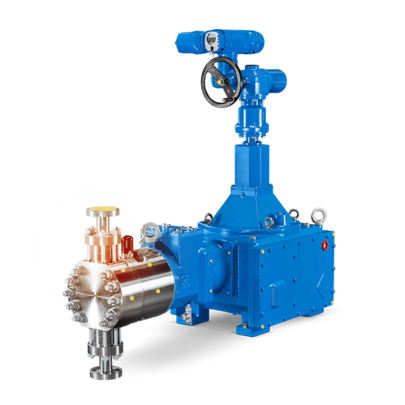

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

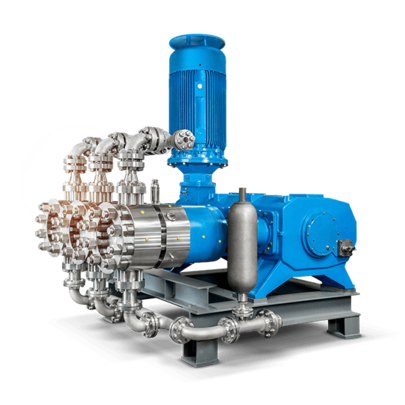

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

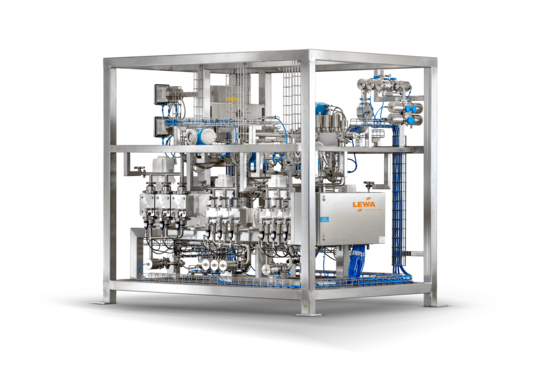

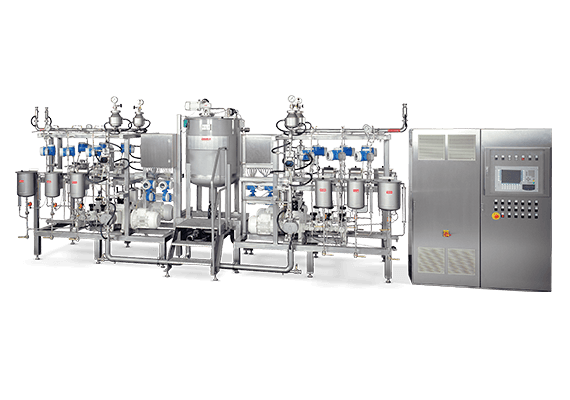

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

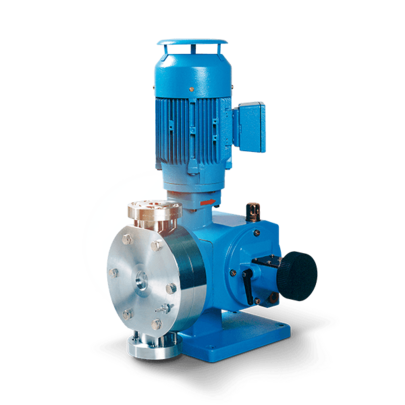

More DetailsLEWA triplex®: High-Pressure Homogenizing Process Pumps

The LEWA triplex homogenizing pump utilizes hermetic diaphragm technology, making it ideal for sensitive applications such as ready-to-drink products, infant food, nutraceuticals, and enteral nutrition. Designed to handle demanding fluids, it finds optimal use in the food, beverage, and pharmaceutical industries.

More DetailsHNPM - Micro annular gear pump series HL

Micro annular gear pumps accomplish conventional micro fluidic tasks effectively and efficiently and open up new technological fields.

.

More Details