LEWA’s hygienic food processing solutions

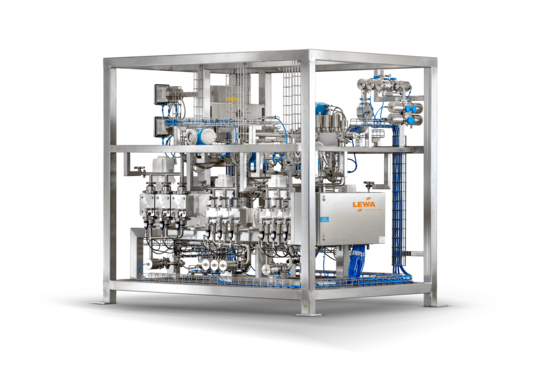

LEWA creates custom-made, complete solutions that are ready to implement in your applications. Accurately metering flavors and colors, in proportion to the flow of acid and gelatin, is crucial to ensure the quality and compliance of your finished products.

Our services range from supplying individual metering units to completely engineering and commissioning injection, mixing, and control systems for batch preparation of products using molding machines, as well as interfaces for existing process control systems. The implementation includes the analysis and application of CE/ATEX 2014/34/EU regulations for potentially flammable products.

The integrity of each process, as well as reliable products and formulas that comply with regulations are core requirements in food technology. Easy cleaning and hygienic aspects are key: each process must remain closed. In every phase of production, manufacturers must avoid the contamination of process fluids.

LEWA supplies precise system solutions that are tailored to the food and beverage industries’ homogenization, mixing, and filling processes.

Advantages

Advantages of LEWA color and flavor metering systems:

- Suitable for all types of flavors and colorants, including plant-based substances

- Extremely compact system

- Highly customizable injection flow, from 0.5 to 100 mg/min

- Reliable, flexible processes guaranteed through mass flow rate control and regulation

- Ability to store up to 100 recipes and replicate processes

- Injected products will not deteriorate due to heat generated by the system

- No coagulation due to cold spots

The entire system is easy to use and maintain:

- Smart layout and easily accessible pipe system

- Hinged doors with wide openings

- Easily removable side parts (for maintenance)

- Materials that come in contact with your products comply with Food Grade regulations

- Automatic cleaning cycle with water and/or additives

Industries

Pumps and Systems for the Food and Beverage Industry

LEWA supports producers and plant construction companies in the food and beverage industries with pumps and systems for homogenization and dispersion, as well as for other processing operations in the food industry. We work with you to plan all the important process-related operations, such as conveying, metering, mixing, heating, and cooling so that you can process your raw product cost-effectively.

More DetailsProducts

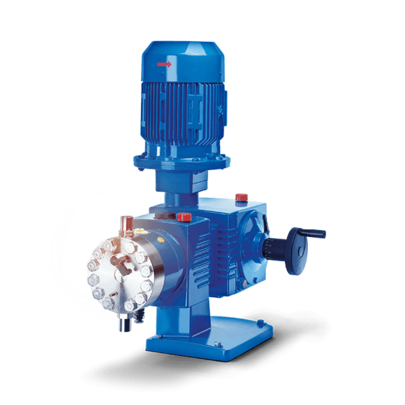

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

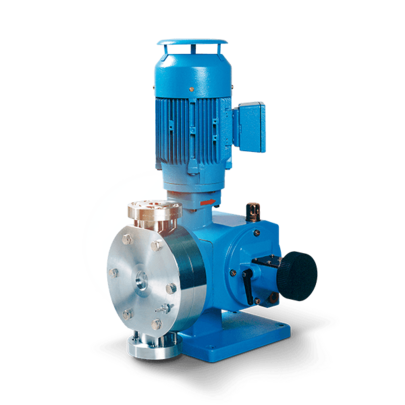

More DetailsLEWA ecoflow®: Hygienic Diaphragm Metering Pumps

Discover the LEWA ecoflow® in its hygienic version, designed for sanitary applications. This versatile metering pump maintains its renowned all-around performance while meeting the stringent hygienic standards required in pharmaceutical and food production industries.

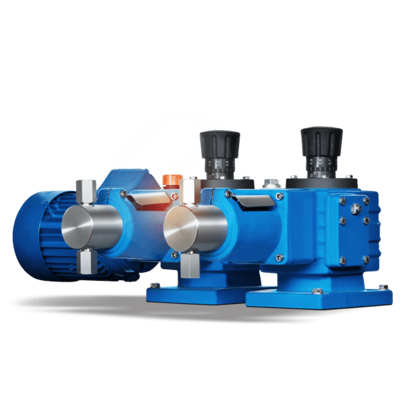

More DetailsLEWA ecoflow® Packed Plunger Metering Pumps

Opt for the LEWA ecoflow packed plunger metering pump, a robust and reliable choice for hassle-free fluid metering. Available in multiple models to suit diverse processes, it's the metering pump trusted by industry leaders for consistent performance.

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

More DetailsLEWA ecodos®: Sanitary / Hygienic Diaphragm Metering Pumps

The LEWA ecodos is also offered in a sanitary/hygienic version, expertly meeting all operational standards for pharmaceutical and food production metering pumps.

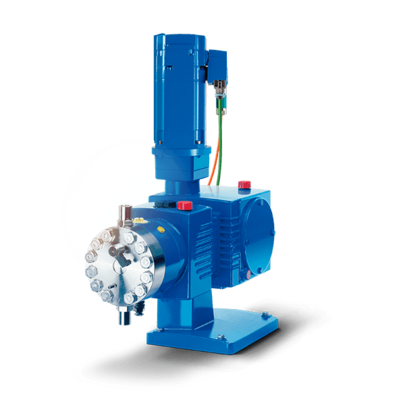

More DetailsLEWA intellidrive®:Mechatronic Diaphragm Metering Pump Technology

Customize both suction and discharge strokes to fit your precise specifications with the LEWA intellidrive® diaphragm metering pump. This technology allows you to individually shape pumping characteristics, ensuring optimal metering for your applications.

More DetailsCustomer-Specific Metering, Mixing or Filling Systems from LEWA

Customer-specific batch/continuous systems for your production process. Metering, mixing, filling, separating, controlling temperature: We work with you to develop the ideal process-related sequence and produce the system that fits your production process – right up to the end product.

More Details