Solutions

Safe pumping of fuels through metering of antistatic additives using LEWA metering systems

- Autarkic closed loop system

- Self-monitoring and regulating system: The conductivity of the fuel is continuously measured and monitored by means of appropriate instruments or sensors

- LEWA smart control

- Fast achievement of the desired concentrate, no long settling times

- Coverage of a large control range

- Mixing tank with electric agitator

- Drip trays for 100 % of the system’s capacity

- Leakage control, level indicator, flow meter, check and shut-off valves

- High quality materials such as stainless steel 316/316L (1.4401/1.4404)

- Consideration of common legal norms and standards (ATEX, WHG, TA-Luft)

Background

Every material or object contains positive and negative electrical charges. Normally, the electrical charges are balanced out. The object is electrically neutral. An electrostatic charge occurs when the object is moved. The charge arises from a contact or friction between two objects and a subsequent separation. The process is referred to as a triboelectric effect or as tribo-electricity. There is an electron transfer from one material or substance to another. The effect occurs both for solids and liquids.

Due to the low conductivity of fuels, the described effect occurs at conveying substances such as gasoline, petroleum or kerosene. If discharge sparks form, this can lead to a fatal explosion in an appropriate atmosphere. The consequences range from the loss of the product through the destruction of equipment and machinery to the mortal danger of people working in the vicinity of the pipeline.

For this reason, a small amount of antistatic agent is added to the fuels. Antistatic additives reduce the risk of electrostatic charge by improving the dissipation of excess electrical charges.

LEWA metering systems ensure a correct addition of antistatic agents to set the fuel’s conductivity. Often only extremely small amounts are required. A diluted antistatic agent solution can then be provided in a mixing container. The diluted solution is added from the mixing container into the fuel pipeline in small quantities. Using appropriate instruments and a control cabinet with LEWA smart control, the conductivity of the fuel in the pipeline is constantly monitored and, if necessary, re-adjusted in a closed loop.

Industries

Chemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsProducts

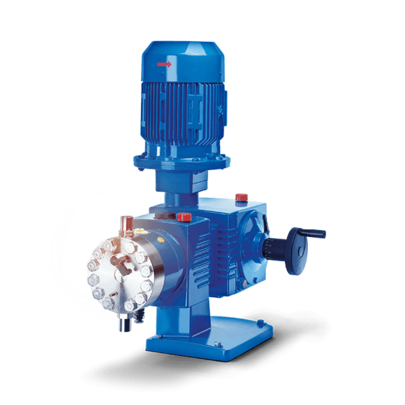

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

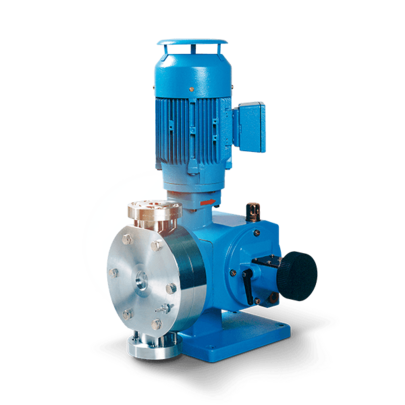

More DetailsLEWA ecodos®: Mechanical Diaphragm Metering Pumps

The LEWA ecodos metering pump delivers absolute reliability, cost-efficiency, and adaptability for applications preferring non-diaphragm actuation. Trust in our proven modular system to design the optimal metering pump tailored to your specific needs.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details