Solutions

The following advantages are offered by LEWA metering diaphragm pumps:

- Hermetically tight: No foreign substances or germs penetrate nor valuable substances escape, ensuring the highest standards of hygiene, thus product recalls are prevented

- Fulfills high pressure requirements: Precise metering and mixture for quality assurance is ensured

- Fulfillment of GMP requirements in the cosmetics sector:

- No use of alcohols and preservatives require a high hygienic status of the pump

- Compositions according to new trends: sensitive natural products are gently metered

- Can be used for a wide variety of cosmetics (shaving creams, shower creams, etc.

- Flexibly adjustable: The flow rate can be adjusted by means of a manual stroke adjustment for different recipes

- CIP and SIP possible

- Recipe constancy and reliability

- Use of FDA-compliant material

- Heated pump heads: Better control of viscosity e.g. the fat phase

- Allergenic gaskets

Background

Finely dosed

In the production of skin creams, various ingredients such as paraffins, hydrocarbons, vegetable fats and oils, and animal waxes are utilized. In order to stabilize the emulsion-like cream structures, emulsifiers are used. Some creams with a high water content need to be preserved for durability. The LEWA diaphragm pumps and systems meter and mix water, alcohols, perfumes, glycerin and other substances necessary for the production of skin cream.

Industries

Pumps and Systems for the Production of Personal Care Products

Processes with strict quality and hygiene requirements, such as GMP or the need to avoid preservatives, require the right equipment. We support you in the selection and the design of hygienic components and systems for producing personal care products. Contact our experts and let us advise you – we will work with you to develop customized metering solutions for your process, such as for manufacturing personal care products.

More DetailsPumps and Systems for the Pharmaceuticals, Life Sciences and Biotechnology Industries

As the leading manufacturer of pumps and pump systems for the pharmaceutical, life sciences, and biotechnology industries, LEWA supports you during the development of complete solutions, which meet your process requirements exactly. Special expertise is required in the production of pharmaceuticals in order to ensure that legal requirements are met. Reliability when it comes to production, documentation, and validation are our top priorities.

More DetailsProducts

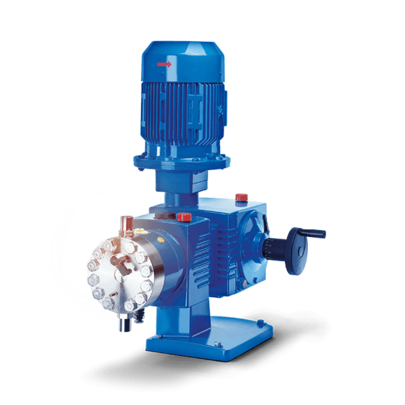

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

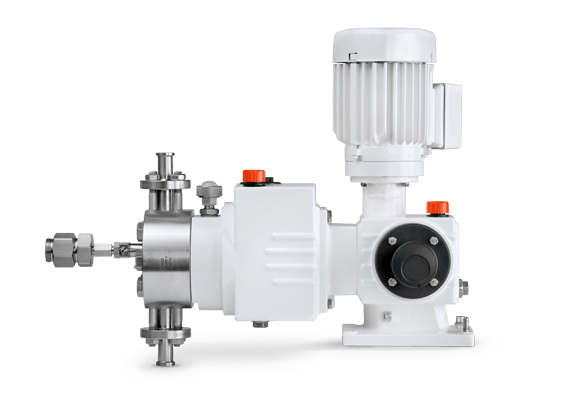

More DetailsLEWA ecoflow®: Hygienic Diaphragm Metering Pumps

Discover the LEWA ecoflow® in its hygienic version, designed for sanitary applications. This versatile metering pump maintains its renowned all-around performance while meeting the stringent hygienic standards required in pharmaceutical and food production industries.

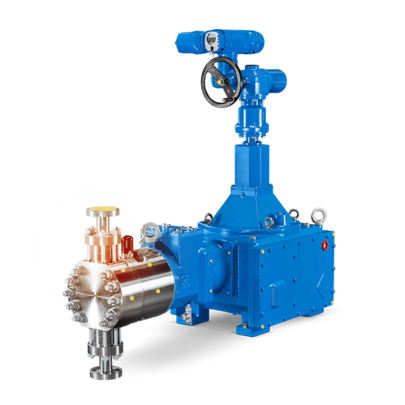

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

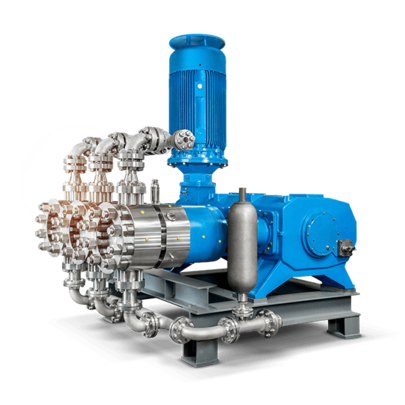

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More DetailsCustomer-Specific Metering Systems from LEWA

Turnkey metering system in closed loop control with monitoring and plausibility testing equipment. Your individually configured metering system with an optimally designed pump for fluid metering in automated processes.

More Details