Solutions

High pressure? Hot temperatures? No problem!

Advantages of LEWA remote-head diaphragm pumps:

- Operating temperatures up to +500 °C

- Pump heads with hydraulically actuated PTFE diaphragm for operating pressures up to +500 bar

- Hermetically tight

- Permanent diaphragm monitoring

- Space-saving design

Background

Handling heavy oil residues – but how?

Crude oil must be cleaned, broken and refined after production until the final products suitable for sale are produced. About 95% of the oils can be processed directly in refineries. Five percent of heavy oil are left. Hydroconversion helps to exploit these leftovers by producing clean fuels and petrochemical raw materials. Various catalytic processes remove heteroatoms, such as sulfur or nitrogen, and convert large carbon-water molecules into smaller ones. The hydroconversion ensures a clean, residue-free oil processing of almost 100%.

Industries

Pumps and Metering Systems for Distillation Plants and Applications in Refineries

Crude oil must be cleaned, separated, and converted (refined) until the final products suitable for sale are made (e.g., gas, diesel, heating oil, lubricants, propane, butane). LEWA supports you with pumps and metering systems, which are used in the refining process during chemical metering. Application with our products are distillation plants, coker, cracker, or visbreaker, for example. Ask our experts for more information!

More DetailsChemical Pumps and Metering Packages for the Chemical Industry

When critical, environmentally hazardous, toxic, or flammable fluids and suspensions need to be reliably conveyed or metered in high-pressure processes, there is no alternative to hermetically sealed metering pumps, process diaphragm pumps, and metering systems from LEWA. Hermetically sealed LEWA pumps with pressures up to 1200 bar are the first choice for the production of chemical intermediate and end products. Contact our experts and let us advise you about your individual chemical pump or system solution!

More DetailsProducts

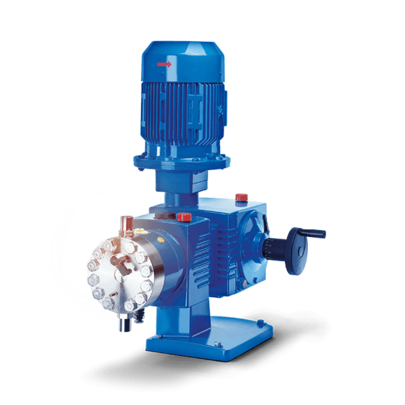

LEWA ecoflow® Diaphragm Metering Pump

LEWA ecoflow: The Innovative Universal Metering Pump with DPS Diaphragm Protection. Trusted across all industries, this modular system pump excels in a wide range of applications. Experience unparalleled versatility and reliability with our ecoflow, the ultimate choice in metering pump technology.

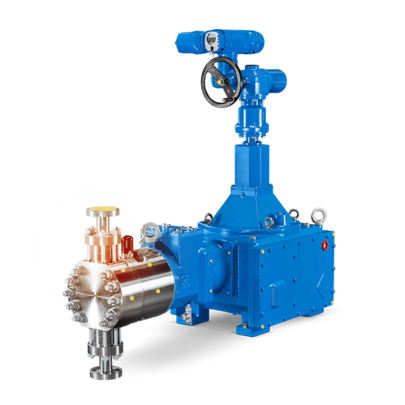

More DetailsLEWA ecoflow®: Process Pumps for High-Pressure Applications

The innovative ecoflow diaphragm process pump excels in high-pressure applications across industries including oil and gas, refinery, petrochemicals, pharmaceuticals, biotechnology, and food and beverage production.

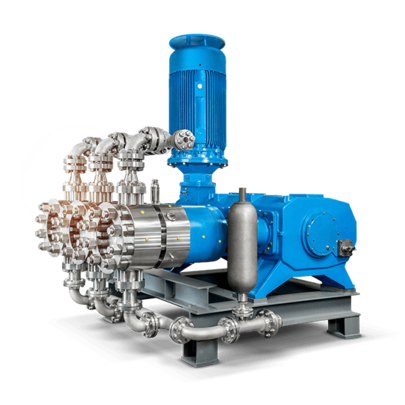

More DetailsLEWA triplex®: Compact Process Pumps for High-Pressure Applications

The LEWA triplex process diaphragm pump stands out as one of the world's most compact high-pressure pumps, ideal for installation in confined spaces. Renowned for its robustness, it has demonstrated exceptional performance across various high-pressure processes in multiple industries.

More Details